Usine de traitement d'eau Éléments de cartouche de filtre à membrane RO Membrane d'osmose inverse remplacée

Description du produit

Each membrane element is housed in a durable, chemical-resistant wrap that ensures stability under varying pressures and temperatures. With consistent salt rejection rates (up to 98.5%) and a high permeate flow rate, our RO membrane cartridges are ideal for applications that demand purity, efficiency, and reliability.

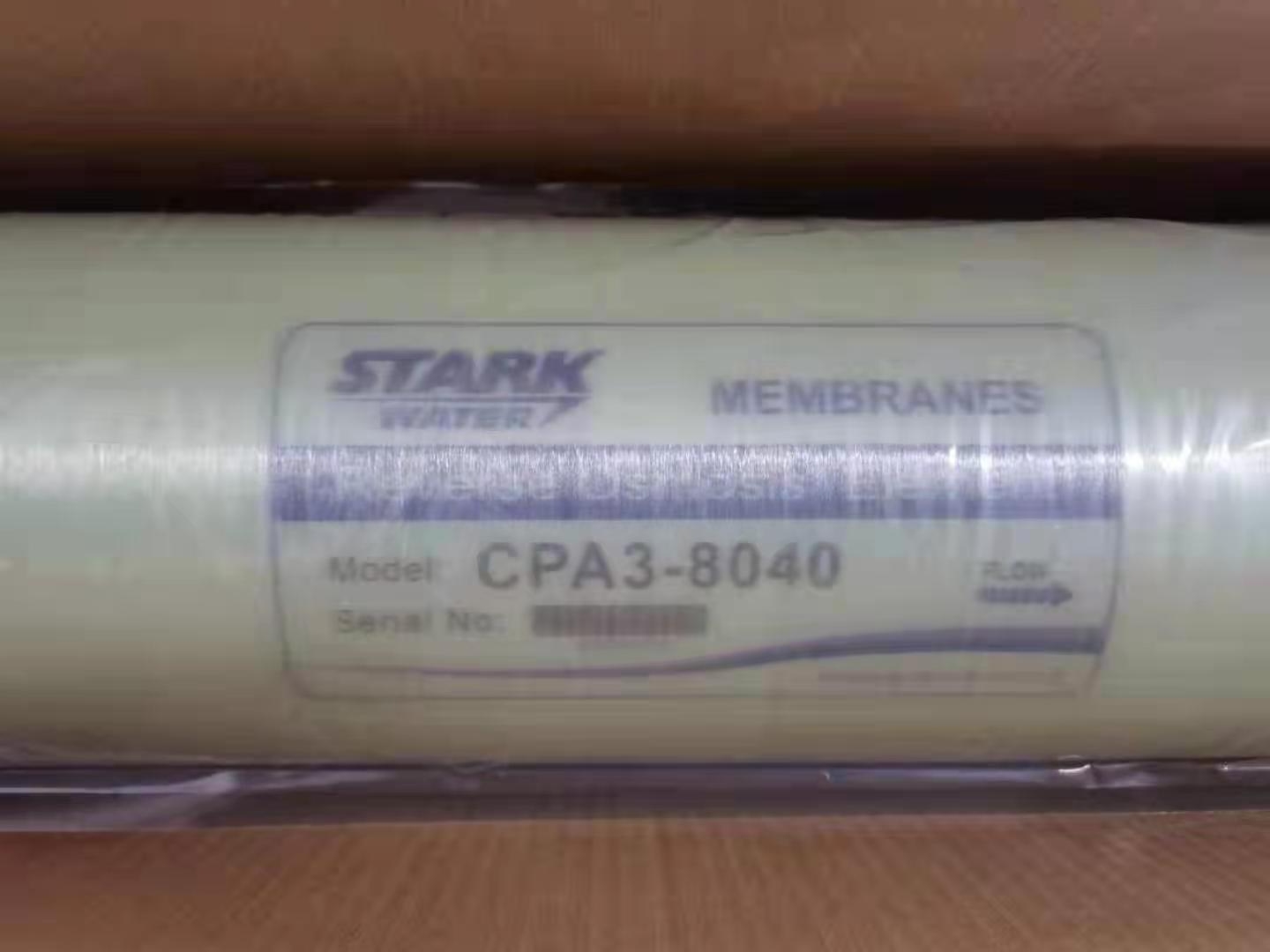

STARK provides a wide range of configurations—including 4040 and 8040 sizes—suitable for small commercial RO systems to large-scale municipal water plants. Each membrane undergoes quality control testing to ensure performance consistency before shipping.

Whether used as a replacement cartridge or as part of a new installation, STARK’s membrane elements are designed to integrate smoothly with standard reverse osmosis systems, offering minimized downtime and easy replacement procedures. The membranes are suitable for brackish water, tap water, and pre-treated seawater systems.

Industries we serve include pharmaceutical manufacturing, food & beverage processing, electronics production, and municipal drinking water treatment. The cartridges also support custom OEM/ODM requirements to match specialized RO system designs.

Paramètres du produit

- Product Type: Reverse Osmosis Membrane Cartridge

- Membrane Material: Thin-Film Composite (TFC)

- Available Sizes: 4040 / 8040 (Custom sizes available upon request)

- Operating Pressure: 150 – 300 psi (10 – 20 bar)

- Max Operating Temperature: 45°C (113°F)

- Taux de rejet du sel : ≥98.5%

- Permeate Flow Rate: 2400 – 11000 GPD (depending on size)

- pH Range (Continuous Operation): 3 – 10

- Chlorine Tolerance: <0.1 ppm (pre-treatment required)

- Connector Type: Standard male/female end caps or customized fittings

- Certifications: ISO 9001, CE (optional NSF on request)

Industrie concernée

- Pharmaceutical & Biotech: Used in ultra-pure water systems for drug formulation, rinsing, and lab-grade applications.

- Food & Beverage: Applied in bottled water production, ingredient blending, and CIP rinse cycles to meet hygiene standards.

- Electronics & Semiconductors: Ensures ultrapure water quality for chip cleaning, circuit board manufacturing, and precision rinsing processes.

- Municipal Water Supply: Integrated into public water treatment plants for removing hardness, heavy metals, and pathogens.

- Seawater Desalination: Used in brackish and seawater RO systems for producing potable or industrial-grade water.

- Chemical & Textile Industries: Facilitates demineralized water generation for chemical blending, dyeing, and rinsing operations.

- Commercial Buildings & Institutions: Installed in schools, hospitals, and hotels to ensure safe and reliable water delivery.

Avantage 1

Advantage 1: Superior Filtration Efficiency

The STARK reverse osmosis membrane cartridge delivers exceptional salt rejection performance, achieving up to 98.5% removal of dissolved solids, organics, and heavy metals. Its advanced thin-film composite structure ensures optimal filtration precision while maintaining high flow rates. This results in reduced energy consumption and enhanced operational efficiency, especially in large-scale water treatment applications. Whether you’re operating in a pharmaceutical-grade clean environment or a high-demand industrial process, the membrane maintains consistent water quality over extended operation periods.Avantage DEUX

Advantage 2: Durability and Easy Maintenance

Constructed with robust, high-performance materials, the STARK reverse osmosis membrane cartridge is engineered to withstand harsh water conditions and long operational hours. Its chlorine-tolerant design (≤0.1 ppm) and broad pH compatibility (3–10) help reduce fouling and membrane degradation, ensuring extended service life. The standardized 4040 and 8040 configurations allow for easy installation and replacement, minimizing system downtime. With minimal cleaning cycles required and lower frequency of replacements, users benefit from reduced maintenance costs and higher system uptime—making it a cost-effective long-term solution for continuous water purification needs.Produits apparentés

Produits similaires

FAQ

Q1 : Quelle est la durée de vie du système d'osmose inverse ?

La durée de vie d'un système d'osmose inverse dépend de la qualité de l'eau et de l'entretien. En règle générale, la membrane dure 2 à 3 ans, tandis que le système lui-même peut durer plus de 10 ans s'il est bien entretenu.

Q2 : Le système peut-il être personnalisé en fonction des différentes conditions de l'eau ?

Oui, tous nos systèmes sont entièrement personnalisables. Nous analysons vos besoins en matière de rapports sur l'eau et d'applications avant de vous proposer des solutions sur mesure.

Q3 : Quelles sont les normes auxquelles répondent les équipements STARK ?

Nos produits sont conformes aux normes CE et ISO 9001 et peuvent être conçus pour répondre à des réglementations régionales spécifiques ou à des normes industrielles sur demande.

Q4 : Quel est le délai de livraison des systèmes STARK RO ?

Les systèmes standard sont expédiés dans un délai de 7 à 15 jours. Pour les commandes personnalisées, le délai peut aller jusqu'à 20-25 jours en fonction de la complexité.

Q5 : Fournissez-vous une assistance technique ou des conseils d'installation ?

Oui. Nous fournissons une documentation technique complète, des conseils à distance par vidéo et nous pouvons envoyer des ingénieurs à l'étranger sur demande.

Q6 : Qu'est-ce qui est inclus dans votre devis ?

Notre devis comprend le système RO complet, le panneau de contrôle, les pompes, les unités de prétraitement et tous les accessoires nécessaires. Les outils d'installation et les pièces de rechange peuvent être inclus sur demande.