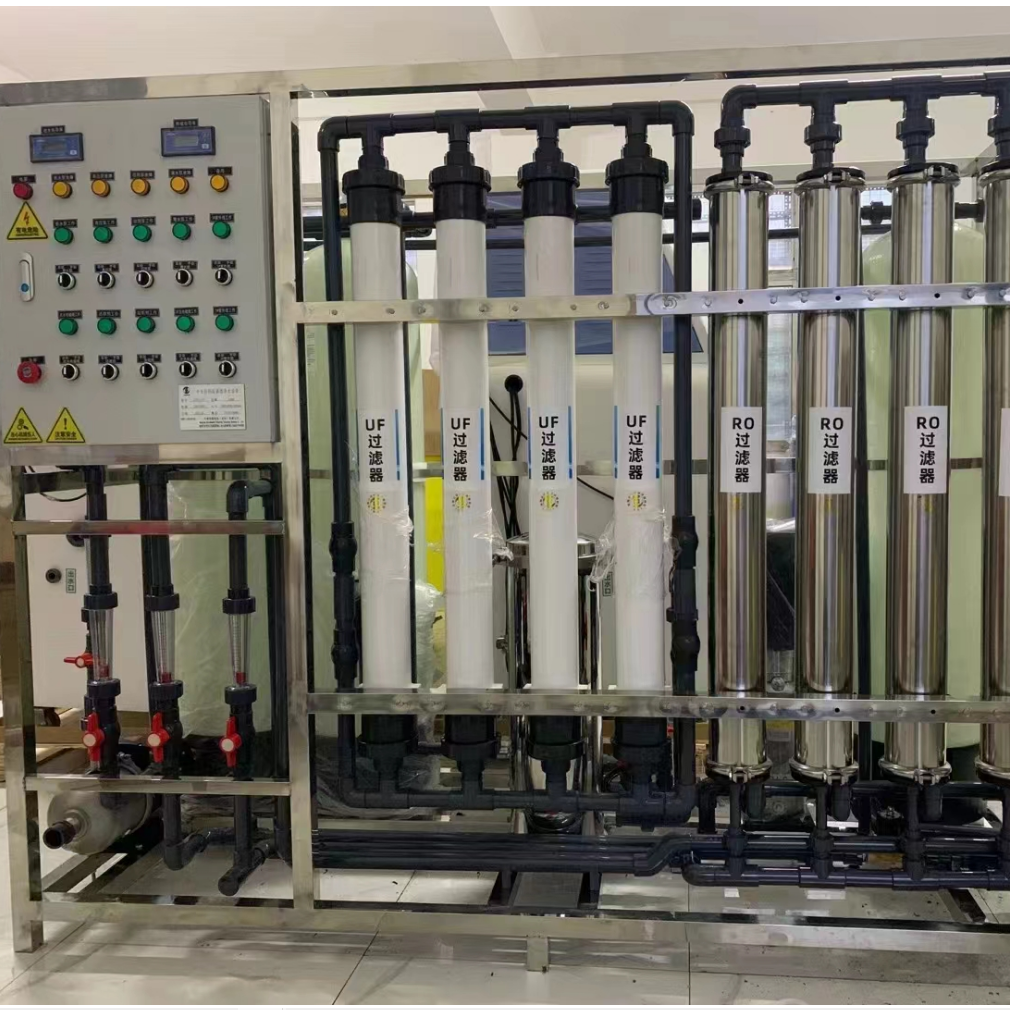

Système d'osmose inverse Fabricant de matériel d'osmose inverse pour l'eau

Source high-quality Ultrafiltration systems directly from Stark Water, a leading UF equipment manufacturer. We specialize in advanced UF equipment and its integration with Reverse Osmosis systems for comprehensive water purification, offering tailored solutions for diverse industrial and commercial needs.

Description du produit

In the global landscape of water purification, the demand for high-quality Ultrafiltration (UF) technology is continuously growing, driven by stringent water quality standards and the need for efficient pre-treatment solutions. Stark Water stands as a prominent UF equipment manufacturer, dedicated to designing, producing, and supplying advanced Ultrafiltration systems that deliver exceptional clarity and contaminant removal. Our commitment to direct manufacturing ensures that every piece of UF equipment meets the highest standards of performance, reliability, and long-term value.

As a Leading UF Equipment Manufacturer: Quality and Expertise

Our identity as a specialized UF equipment manufacturer means we control the entire production process, from concept and design to fabrication and rigorous testing. This comprehensive approach offers distinct advantages to our clients:

- Guaranteed Quality: Strict quality control procedures at every stage ensure that each UF system is built to exacting standards, providing consistent performance and durability.

- Direct from Source: Clients benefit from direct sourcing, which often translates to competitive pricing and transparent communication regarding product specifications and capabilities.

- Expertise and Innovation: Our dedicated R&D and engineering teams continuously work on enhancing UF technology, incorporating the latest advancements in membrane science and system design to offer cutting-edge solutions.

- Customization (OEM/ODM): As a manufacturer, we offer extensive OEM and ODM capabilities, allowing for the customization of UF systems to meet specific client requirements, branding needs, or unique project parameters.

We supply a wide range of UF equipment, from individual modules to complete skid-mounted systems, ready for seamless integration into diverse water purification applications.

Integrating Ultrafiltration with Reverse Osmosis System Water Purification

Ultrafiltration plays a pivotal role in optimizing overall water purification systems, particularly when integrated with a reverse osmosis system. While RO effectively removes dissolved solids, UF excels at physically removing suspended solids, turbidity, colloids, bacteria, and viruses. When used as a pre-treatment for RO, UF significantly enhances the performance and extends the lifespan of sensitive RO membranes by:

- Reducing Fouling: Preventing larger particles and microorganisms from accumulating on the RO membrane surface.

- Lowering SDI: Achieving a very low Silt Density Index (SDI), a critical parameter for RO feed water quality.

- Minimizing Chemical Use: Reducing the need for chemical pre-treatment often associated with conventional RO pre-filtration.

This synergy creates highly efficient water purification systems capable of treating a broad spectrum of raw water sources, delivering exceptional water quality for even the most demanding industrial, municipal, and commercial needs. Our expertise as a UF equipment manufacturer allows us to design and provide integrated solutions for superior water treatment.

Paramètres du produit

As a leading UF equipment manufacturer, Stark Water designs and produces Ultrafiltration systems with versatile and high-performance specifications. Here are typical and customizable technical parameters:

| Paramètres | Spécifications / Options de personnalisation |

|---|---|

| Concentration sur les mots-clés essentiels | uf equipment manufacturer capabilities and product specifications. |

| Capacité du système | Customizable, ranging from 1 m³/hr to 1000+ m³/hr (or GPM equivalent). Specified as per client requirements. |

| Technologie de filtration | Ultrafiltration (UF) Filtration sur membrane. |

| Type de membrane | Hollow Fiber UF Membrane (e.g., PVDF, PES, PAN), chosen based on feed water characteristics and application. |

| Taille des pores | Typically 0.01 μm – 0.1 μm (e.g., 0.02 μm, 0.03 μm), selected for specific contaminant removal. |

| Mode de fonctionnement | Outside-in or Inside-out flow. Can be operated in dead-end or cross-flow filtration modes. Designed for optimal flux. |

| Pression de fonctionnement | Typically 0.05 – 0.2 MPa (0.5 – 2 Bar / 7 – 29 PSI). Low pressure operation, customized for efficiency. |

| Compatibilité des sources d'eau brute | Municipal Water, Well Water, Surface Water (rivers, lakes), Pre-treated Wastewater. Customizable based on detailed raw water analysis. |

| Résultats Qualité de l'eau | Turbidity Reduction: >99%; TSS Reduction: >99%; Bacteria/Virus Removal: >99.9999% (log 6 reduction or higher). SDI < 3. Achieves clarity suitable for RO feed. |

| Système de contrôle | Fully Automatic PLC Control with HMI. Customized for specific automation needs, including auto-backwash, chemical cleaning-in-place (CIP) sequences, alarm management, and remote monitoring/SCADA integration. |

| Alimentation électrique | 3 Phase (380V/415V/460V, 50Hz/60Hz) or Single Phase (220V), customized as per regional standards. |

| Matériaux de construction |

|

| Dimensions | Customized skid-mounted or modular design to fit client’s specific space requirements. |

| Température de fonctionnement | 5°C - 45°C (selon le matériau pour une plage plus large). |

| Certification | Designed and manufactured to meet relevant international standards (e.g., ISO, CE, upon request). OEM/ODM capabilities include meeting specific client standards. |

Industrie concernée

As a leading UF equipment manufacturer, Stark Water supplies its high-quality Ultrafiltration systems for a broad spectrum of industrial, municipal, and commercial sectors requiring advanced physical separation and robust pre-treatment. Our UF equipment is ideal for:

- Municipal Drinking Water Treatment: Provides primary purification or robust pre-treatment for urban waterworks, effectively removing turbidity, suspended solids, bacteria, and viruses from surface water sources to produce safe potable water.

- Reverse Osmosis System Water Pre-treatment: Essential for protecting sensitive RO membranes from fouling by suspended solids, colloids, and microorganisms, significantly extending RO membrane lifespan and reducing cleaning frequency.

- Wastewater Treatment & Reuse: Core component in advanced municipal and industrial wastewater treatment facilities (e.g., as part of Membrane Bioreactor (MBR) systems or tertiary treatment), producing high-quality effluent suitable for discharge, irrigation, or industrial reuse.

- Food & Beverage Industry: Used for clarification of process water, juices, wine, beer, and other beverages; and pre-treatment prior to sterile processes, ensuring product clarity and safety.

- Pharmaceuticals & Biotechnology: Provides purified water for process use and pre-filtration for sterile applications, ensuring high purity and compliance.

- Industrial Process Water: Supplies clean process water for various manufacturing operations, preventing fouling of equipment and improving product consistency.

- Tour de refroidissement et eau d'alimentation des chaudières : Élimine les solides en suspension et la charge microbienne de l'eau d'appoint, empêchant ainsi l'entartrage et l'encrassement biologique et améliorant l'efficacité des grands systèmes d'utilité publique.

- Mining Operations: For treating process water and wastewater containing high levels of suspended solids and colloids.

- Fabrication de produits électroniques (Pré-UPW) : Employé dans les étapes de prétraitement des systèmes d'eau ultra-pure (UPW), assurant l'élimination des particules afin de protéger la purification en aval pour la fabrication de produits électroniques sensibles.

- OEM/ODM Partnerships: We manufacture UF equipment for other system integrators, distributors, and equipment suppliers under their brand, providing custom-designed solutions for their markets.

Avantage 1

Stark Water, as a dedicated UF equipment manufacturer, offers the significant advantage of direct-from-manufacturer quality and extensive customization capabilities. We control the entire production process from R&D to fabrication and testing, ensuring every Ultrafiltration system is built to the highest standards of performance and durability. This direct approach translates into guaranteed product authenticity, reliable support, and competitive pricing due to reduced intermediaries. Furthermore, our OEM/ODM capabilities allow us to custom-engineer UF equipment precisely to your unique specifications—including capacity, dimensions, raw water characteristics, and integration needs—providing a tailored solution that optimizes efficiency and perfectly fits your project requirements, ensuring seamless integration with your reverse osmosis system or standalone purification plant.

Avantage DEUX

Our Ultrafiltration equipment delivers superior filtration performance and optimized integration with Reverse Osmosis system water purification, enhancing overall water treatment efficiency. UF membranes provide a robust physical barrier, effectively removing suspended solids, turbidity, colloids, bacteria, and viruses, achieving exceptional water clarity. When utilized as a pre-treatment for RO, our UF equipment significantly extends the lifespan of sensitive RO membranes by preventing fouling, reducing chemical usage, and improving RO feed water quality. This synergy ensures more reliable and cost-effective operation for your entire water purification system, minimizing maintenance, reducing downtime, and consistently producing high-quality pure water for various demanding industrial, municipal, and commercial applications, thereby maximizing your return on investment.

Produits apparentés

Produits similaires

- Système de dessalement de l'eau de mer

STARK Factory prix compétitif 2000LPH système de dessalement de l'eau de mer système de traitement de l'eau système de filtrage

Lire la suite

FAQ

Q1 : Quelle est la durée de vie du système d'osmose inverse ?

La durée de vie d'un système d'osmose inverse dépend de la qualité de l'eau et de l'entretien. En règle générale, la membrane dure 2 à 3 ans, tandis que le système lui-même peut durer plus de 10 ans s'il est bien entretenu.

Q2 : Le système peut-il être personnalisé en fonction des différentes conditions de l'eau ?

Oui, tous nos systèmes sont entièrement personnalisables. Nous analysons vos besoins en matière de rapports sur l'eau et d'applications avant de vous proposer des solutions sur mesure.

Q3 : Quelles sont les normes auxquelles répondent les équipements STARK ?

Nos produits sont conformes aux normes CE et ISO 9001 et peuvent être conçus pour répondre à des réglementations régionales spécifiques ou à des normes industrielles sur demande.

Q4 : Quel est le délai de livraison des systèmes STARK RO ?

Les systèmes standard sont expédiés dans un délai de 7 à 15 jours. Pour les commandes personnalisées, le délai peut aller jusqu'à 20-25 jours en fonction de la complexité.

Q5 : Fournissez-vous une assistance technique ou des conseils d'installation ?

Oui. Nous fournissons une documentation technique complète, des conseils à distance par vidéo et nous pouvons envoyer des ingénieurs à l'étranger sur demande.

Q6 : Qu'est-ce qui est inclus dans votre devis ?

Notre devis comprend le système RO complet, le panneau de contrôle, les pompes, les unités de prétraitement et tous les accessoires nécessaires. Les outils d'installation et les pièces de rechange peuvent être inclus sur demande.