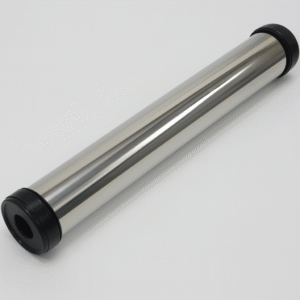

STARK High Quality Customized Membrane Housing best membrane housing 8 Inch Ro Membrane Housing

Optimize your RO system with Stark Water’s High Quality Customized Membrane Housing. As the best membrane housing for 8-inch RO elements, this durable customized membrane housing is precisely engineered to meet your specific industrial reverse osmosis needs, ensuring superior performance and leak-proof reliability.

Description du produit

In the realm of high-performance Reverse Osmosis (RO) systems, the membrane housing is far more than just a containment vessel; it’s a precision-engineered pressure vessel that directly impacts system efficiency, safety, and lifespan. The Stark Water High Quality Customized Membrane Housing stands as the definitive choice for demanding industrial and commercial applications, representing the best membrane housing solution specifically tailored to your unique operational requirements. This is where bespoke design meets uncompromising quality, ensuring optimal performance for your RO purification infrastructure.

Precision Tailoring: The Essence of a Customized Membrane Housing

The core advantage of our offering lies in its truly customized membrane housing design. We understand that every industrial RO system has specific pressure demands, water chemistries, spatial constraints, and integration needs. Our engineering process involves close collaboration to precisely tailor every aspect of the 8 Inch Ro Membrane Housing:

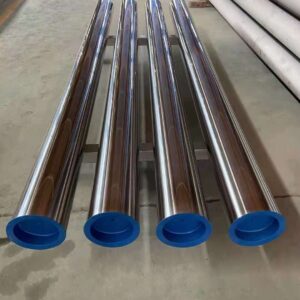

- Material Selection: From standard SUS304 to highly corrosion-resistant SUS316L or even Duplex Stainless Steel, chosen based on feedwater aggressivity and pressure requirements.

- Pressure Rating: Designed to safely accommodate specific operating pressures, from standard brackish water RO (e.g., 300 PSI, 450 PSI) to high-pressure seawater desalination (e.g., 1000 PSI, 1200 PSI).

- Porting & Configuration: Customizable end-entry or side-entry ports, various port sizes, and configurations for single or multiple membrane elements (e.g., 1-element to 7-element housings).

- Connection Types: Tailored to your piping system (threaded, flanged, victaulic connections).

- Finition de la surface : Internal and external finishes optimized for hygiene, corrosion resistance, and aesthetics (polished, passivated, painted).

This meticulous customization ensures flawless integration into your existing or new RO plant, maximizing performance, minimizing installation complexities, and providing a perfect fit that generic housings cannot offer.

High Quality & Best Membrane Housing for 8 Inch RO Elements

Our commitment to delivering the best membrane housing is reflected in our unwavering focus on high quality. Each 8 Inch Ro Membrane Housing is manufactured using advanced techniques and undergoes rigorous testing to meet stringent industry standards:

- Superior Weld Integrity: Automated welding processes ensure strong, consistent, and leak-proof seams crucial for high-pressure containment.

- Precision Machining: Ensures exact internal dimensions for optimal membrane seating, preventing bypass and maximizing permeate quality.

- Robust Sealing: High-quality O-rings and end-cap designs provide an absolutely sealed environment, preventing leaks and guaranteeing purified water integrity.

- ASME Code Compliance: Available with ASME U-Stamp certification upon request for ultimate pressure vessel safety and regulatory compliance.

This dedication to high quality and precision engineering ensures exceptional durability, extended operational lifespan, and unparalleled reliability for your industrial RO system, protecting your valuable membranes and guaranteeing consistent water purification.

Paramètres du produit

| Paramètres | Spécifications / Options de personnalisation |

|---|---|

| Concentration sur les mots-clés essentiels | Customized membrane housing et de ses capacités. |

| Taille de la membrane compatible | 8-Inch Diameter x 40-Inch Length (8040) RO Membrane Elements. Custom configurations for 1 to 7+ elements per vessel. |

| Construction matérielle | Stainless Steel (SUS304, SUS316L, or Duplex Stainless Steel). Specified by client for chemical compatibility and pressure. |

| Pression de fonctionnement max. Pression de fonctionnement | Customizable: 300 PSI, 450 PSI, 600 PSI, 1000 PSI, 1200 PSI, or other pressure ratings as required. |

| Type de conception | End-entry or Side-entry ports. Multi-port options (e.g., 2.5″ to 4″ side ports). |

| Connexions portuaires | Threaded (NPT/BSP), Flanged (ANSI/DIN), Victaulic, or custom connections. |

| Type d'embout | Quick-Lock, Threaded, or Bolt-on for secure closure and easy membrane replacement. |

| Matériau d'étanchéité | EPDM, Viton (FKM), Buna-N (NBR) O-rings, selected based on temperature and chemical compatibility. |

| Finition de la surface interne | Polis (par exemple, Ra < 0,6 μm) ou électropolis pour une hygiène et un débit optimaux. |

| Finition de la surface extérieure | Satin, Matte, Brushed, or Painted. |

| Max. Température de fonctionnement | Jusqu'à 49°C (120°F) pour les joints standard ; plus élevés avec des matériaux spécialisés. |

| Matériel de montage | Comprend des selles de montage et des sangles en acier inoxydable. |

| Essais et certification | Hydrostatic pressure tested; ASME Boiler and Pressure Vessel Code (Section VIII, Div 1) U-Stamp available upon request for specific pressure ratings. CE Mark available. |

| Customization Scope | Full ODM capability for bespoke dimensions, pressure ratings, material grades, porting arrangements, and integration features. |

Industrie concernée

- Large Industrial RO Water Treatment Plants: Tailored for municipal drinking water purification, general industrial process water, and utility water systems, ensuring precise water quality and robust operation.

- Installations de dessalement d'eau de mer et d'eau saumâtre : Custom-designed to safely contain RO membranes under extremely high pressures, critical for efficient desalination in coastal cities, island nations, and offshore platforms.

- Pharmaceutical & Biotechnology Production: Engineered for RO systems producing high-purity water (PW, WFI pre-treatment) for drug manufacturing, laboratory use, and sterile processes, meeting stringent GMP and regulatory standards.

- Fabrication de produits électroniques et de semi-conducteurs : Bespoke housings for RO systems that are part of ultra-pure water (UPW) generation facilities, ensuring absolute containment and purity for sensitive chip fabrication and component rinsing.

- Production d'électricité : Customized for RO systems providing boiler feed water pre-treatment and cooling tower make-up water in power plants, optimized for specific pressure and temperature conditions to prevent scaling and corrosion.

- Industrie alimentaire et des boissons : Custom-fitted for RO systems producing high-purity water for beverage formulation (bottled water, soft drinks, breweries), dairy processing, and food ingredient preparation, ensuring product consistency and safety.

- Chemical Processing: Tailored for RO systems purifying water for chemical formulations, dilutions, and various process applications, ensuring purity and preventing unwanted reactions, often in corrosive environments.

- Traitement et réutilisation des eaux usées : Custom-designed for RO stages in advanced industrial or municipal wastewater treatment plants, producing high-quality effluent for discharge or reuse, adhering to specific regulatory compliance.

Avantage 1

Avantage DEUX

Produits apparentés

Produits similaires

- Accessoires pour le traitement de l'eau

Stainless Steel RO Membrane Housing – 8″ Side Entry Series (300 PSI)

Lire la suite - Boîtier de la membrane

Stainless Steel RO Membrane Housing – 4″ End Entry Series (300 PSI)

Lire la suite - Boîtier de la membrane

STARK 4040/8040 Ro FRP Membrane Housing Fabrick High Pressure Vessel Price

Lire la suite

FAQ

Q1 : Quelle est la durée de vie du système d'osmose inverse ?

La durée de vie d'un système d'osmose inverse dépend de la qualité de l'eau et de l'entretien. En règle générale, la membrane dure 2 à 3 ans, tandis que le système lui-même peut durer plus de 10 ans s'il est bien entretenu.

Q2 : Le système peut-il être personnalisé en fonction des différentes conditions de l'eau ?

Oui, tous nos systèmes sont entièrement personnalisables. Nous analysons vos besoins en matière de rapports sur l'eau et d'applications avant de vous proposer des solutions sur mesure.

Q3 : Quelles sont les normes auxquelles répondent les équipements STARK ?

Nos produits sont conformes aux normes CE et ISO 9001 et peuvent être conçus pour répondre à des réglementations régionales spécifiques ou à des normes industrielles sur demande.

Q4 : Quel est le délai de livraison des systèmes STARK RO ?

Les systèmes standard sont expédiés dans un délai de 7 à 15 jours. Pour les commandes personnalisées, le délai peut aller jusqu'à 20-25 jours en fonction de la complexité.

Q5 : Fournissez-vous une assistance technique ou des conseils d'installation ?

Oui. Nous fournissons une documentation technique complète, des conseils à distance par vidéo et nous pouvons envoyer des ingénieurs à l'étranger sur demande.

Q6 : Qu'est-ce qui est inclus dans votre devis ?

Notre devis comprend le système RO complet, le panneau de contrôle, les pompes, les unités de prétraitement et tous les accessoires nécessaires. Les outils d'installation et les pièces de rechange peuvent être inclus sur demande.