160 m³/h UF Water Purifier | Hollow Fiber Ultrafiltration | STARK

Product Description

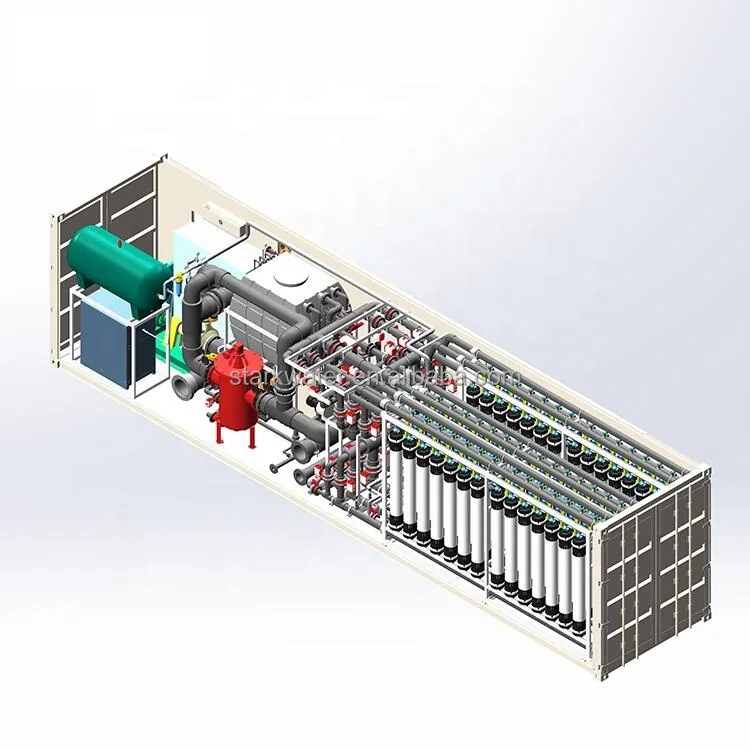

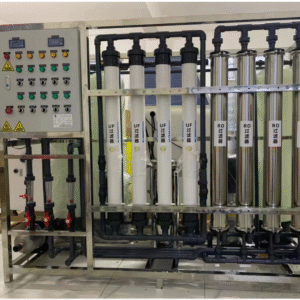

Each rack integrates backwash pumps, air scour and automated chemically enhanced backwash (CEB); periodic CIP (e.g., NaOCl/citric) restores permeability. The PLC sequences transmembrane pressure (TMP) limits, flux, backwash intervals and chemical dosing. Options include inline coagulation for difficult feeds, integrity testing, and UF→RO interlocks.

- Consistent filtrate SDI < 3 for RO pretreatment (when designed with inline coagulation/flux setpoints)

- Modular racks allow future capacity expansion beyond 160 m³/h

- Food-grade or industrial build; SS/UPVC wetted piping per duty

Note: Final design is engineered from feed turbidity/SDI, temperature and fouling indices. Pilot or jar-test data can be used to set flux, recovery and chemical regime.

Product Parameter

Technical Parameters

| Rated Capacity | 160 m³/h (continuous, configurable) |

|---|---|

| Membrane Type | Hollow fiber UF, PVDF or PES/PS, hydrophilic |

| Pore Size (nominal) | ~0.01–0.03 μm |

| Operation Mode | Dead-end with periodic backwash & air scour; CEB/CIP programmable |

| Typical Flux | 60–120 L/m²·h (temperature & feed dependent) |

| TMP Range | 0.05–0.25 MPa typical; max per module spec |

| Recovery | ~90–95% (accounting for backwash/CEB losses) |

| Feed Water Limits | Turbidity ≤ 50 NTU typical (higher with coagulation); SDI < 8 recommended |

| Backwash | Every 20–60 min; filtrate/air; 30–60 s cycles |

| Chemicals | CEB/CIP: NaOCl, citric, NaOH (ranges per membrane OEM); pH 2–12 service |

| Filtrate Quality | Low turbidity; bacteria removal to log levels typical of UF membranes |

| Controls | PLC/HMI with TMP/flux control, integrity/pressure interlocks, data logging |

| Materials | Skid SS304; process piping SS/UPVC/CPVC; instruments SS/PTFE seals |

| Electrical | 380–415 V/50 Hz or 460 V/60 Hz; VFD pumps |

| Footprint | Modular racks; layout per site & access aisles |

| Notes | Values are typical; final BOM & guarantees confirmed after feed study. |

Applicable Industry

- Municipal water & groundwater plants — clarification & polishing

- Industrial RO pretreatment — stable SDI and biofouling control

- Bottled water & beverage — particulate removal and clarity

- Wastewater tertiary treatment & reuse — low-turbidity filtrate

- Desalination pretreatment — seawater/brackish UF before SWRO/ BWRO

- Surface water treatment — algae & pathogen barrier

Advantage One

Advantage 1 — Stable Water Quality & RO-Ready

- UF barrier (~0.01–0.03 μm) for turbidity, colloids and most bacteria

- SDI control supports high RO uptime and longer membrane life

- Inline coagulation option for challenging surface waters

- Automatic integrity & pressure interlocks for safe operation

Advantage TWO

Advantage 2 — Automated, Service-Friendly Operation

- PLC/HMI sequences backwash, air scour, CEB and CIP with recipes

- Modular racks, front access to pumps & valves for quick service

- VFD pumps optimize energy at variable flux and temperature

- Remote support & spare parts through STARK global network

Related Products

Related products

FAQ

Q1: How long does the reverse osmosis system last?

The lifespan of a reverse osmosis system depends on water quality and maintenance. Typically, the membrane lasts 2–3 years, while the system itself can last over 10 years with proper care.

Q2: Can the system be customized based on different water conditions?

Yes, all our systems are fully customizable. We analyze your water report and application needs before providing tailored solutions.

Q3: What standards does STARK equipment comply with?

Our products comply with CE, ISO 9001, and can be designed to meet specific regional regulations or industry standards upon request.

Q4: What is the delivery time for STARK RO systems?

Standard systems are shipped within 7–15 days. For customized orders, lead time may extend to 20–25 days depending on complexity.

Q5: Do you provide technical support or installation guidance?

Yes. We provide full technical documentation, remote guidance via video, and can dispatch engineers internationally upon request.

Q6: What is included in your quotation?

Our quotation includes the full RO system, control panel, pumps, pre-treatment units, and all necessary fittings. Installation tools and spare parts can be included upon request.