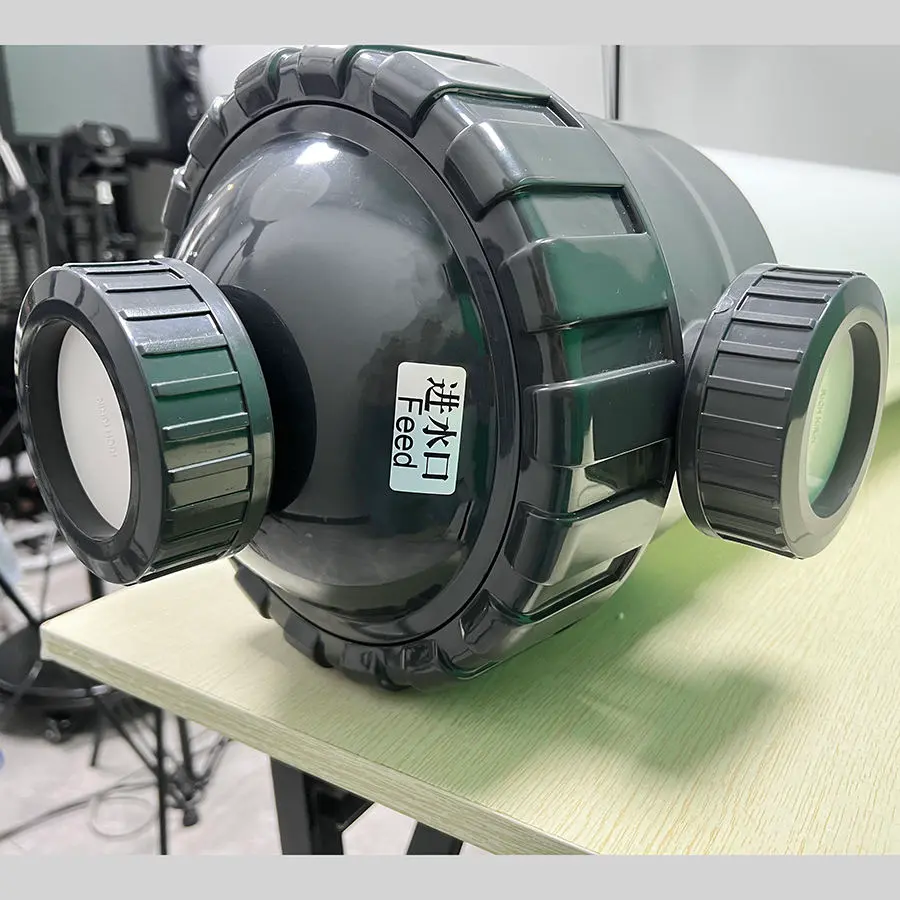

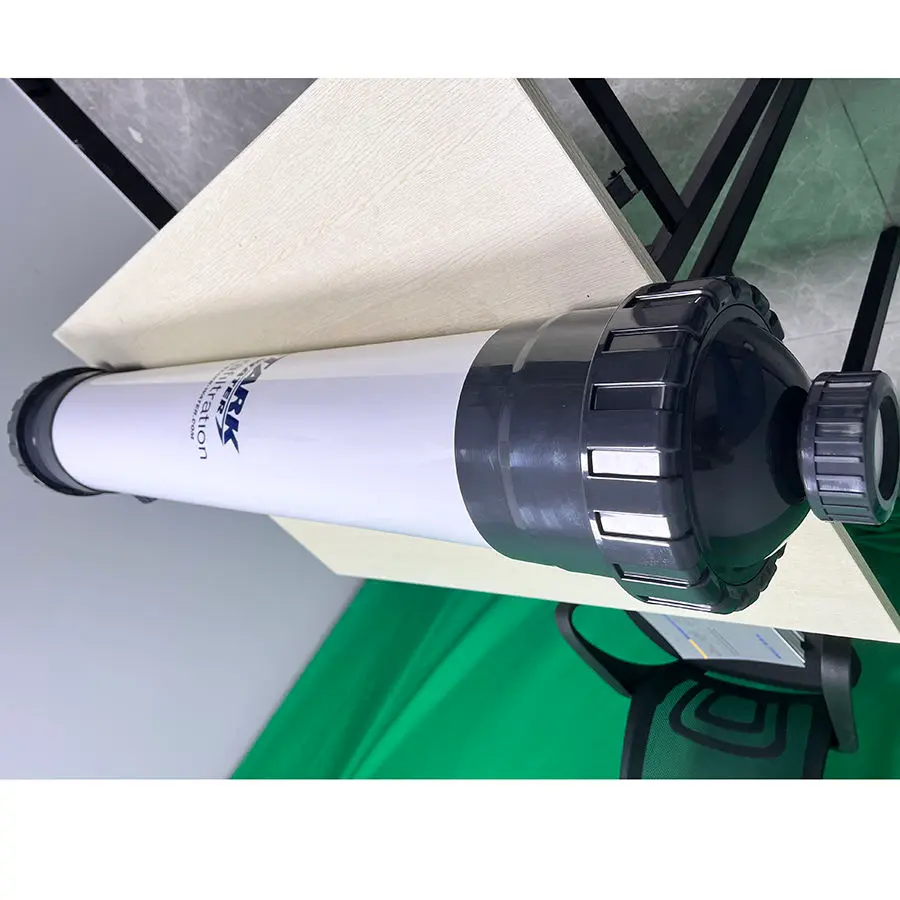

4040 RO Membrane | 4”×40” Reverse Osmosis Element (TFC) | STARK

Product Description

- Stable permeate quality: nominal rejection ≥ 99% on NaCl at 25 °C; smooth surface polyamide for consistent performance.

- Energy flexibility: standard BW elements run ~150–225 psi; LE options target lower pressure at similar flux.

- Serviceability: fits common 4040 vessels; EPDM brine seal; standard 3/4” interconnector ID.

- Designed for pretreatment trains: pair with 20 µm → 5 µm cartridges, carbon/anti-scalant, and UF/clarification as needed to control SDI and biofouling.

Engineering transparency: All ratings are typical and configurable. Guarantees are confirmed against your feed analysis (TDS/SDI, temperature, chlorine, scaling indices) and the selected operating window.

Product Parameter

Technical Parameters (typical values; model-dependent)

| Membrane Type | Thin-Film Composite (TFC) Polyamide |

|---|---|

| Element Size | 4.0″ × 40″ (4040), OD ~3.9″, ID 0.75″ |

| Active Area | ~7.5–8.5 m² (80–90 ft²), depending on model |

| Nominal Salt Rejection | ≥ 99.0% (BW); ≥ 99.2–99.5% for high-rejection variants |

| Typical Permeate Flow | ~2,000–2,800 GPD (7.6–10.6 m³/d) at 25 °C, 2,000 ppm NaCl, pH 7, 15% recovery |

| Operating Pressure | ~1.0–1.6 MPa (150–225 psi) BW/LE; max 4.1 MPa (600 psi) per model limit |

| Feed Water Temperature | 5–45 °C (flux rises with temperature) |

| pH Range (continuous / cleaning) | 2–11 / 1–13 |

| Free Chlorine Tolerance | 0 mg/L (TFC polyamide is chlorine-sensitive; dechlorinate upstream) |

| Max Feed SDI | < 5 recommended; lower for sensitive duties |

| Max Pressure Drop (per element) | ≤ 1.0 bar (15 psi) |

| Recommended Recovery | 10–20% per pressure vessel (system design-dependent) |

| End Connection | Standard 4040 brine seal and interconnector; EPDM O-rings |

| Available Variants | BW4040 (high rejection), LE4040 (low energy), FR4040 (fouling-resistant), SW4040 (seawater / higher pressure) |

| Test Conditions Note | Unless stated otherwise: 2,000 ppm NaCl, 25 °C, pH 7, 15% recovery; your results vary with temperature and pressure. |

Applicable Industry

- Commercial & light-industrial RO systems for municipal/brackish feeds

- Beverage & bottled water polishing

- Boiler make-up & process water

- Electronics pre-DI / polishing trains

- Wastewater reuse after clarification/UF

- Carwash, HVAC, humidification and rinsing lines

Advantage One

Advantage 1 — High Rejection with Flexible Energy Window

- Nominal ≥ 99% salt rejection on NaCl with stable permeate conductivity.

- Low-energy (LE) options to reduce pump pressure and operating cost.

- Fouling-resistant (FR) construction available for difficult feeds.

Advantage TWO

Advantage 2 — Easy Retrofit & OEM Support

- Compatible with standard 4040 pressure vessels and adapters.

- OEM/Private label available; documentation and QC traceability provided.

- Application engineering: element selection, pretreatment and dosing guidance based on your water analysis.

Related Products

Related products

FAQ

Q1: How long does the reverse osmosis system last?

The lifespan of a reverse osmosis system depends on water quality and maintenance. Typically, the membrane lasts 2–3 years, while the system itself can last over 10 years with proper care.

Q2: Can the system be customized based on different water conditions?

Yes, all our systems are fully customizable. We analyze your water report and application needs before providing tailored solutions.

Q3: What standards does STARK equipment comply with?

Our products comply with CE, ISO 9001, and can be designed to meet specific regional regulations or industry standards upon request.

Q4: What is the delivery time for STARK RO systems?

Standard systems are shipped within 7–15 days. For customized orders, lead time may extend to 20–25 days depending on complexity.

Q5: Do you provide technical support or installation guidance?

Yes. We provide full technical documentation, remote guidance via video, and can dispatch engineers internationally upon request.

Q6: What is included in your quotation?

Our quotation includes the full RO system, control panel, pumps, pre-treatment units, and all necessary fittings. Installation tools and spare parts can be included upon request.