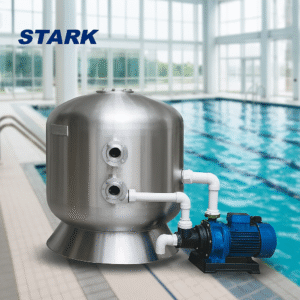

Carbon Steel Mechanical Filter Housing – Epoxy & Rubber Lined Series (Heavy Duty)

Stark Carbon Steel Mechanical Filter (STK2 Series) offers a cost-effective solution for large-scale filtration. Manufactured from heavy-duty Q235B steel (up to 10mm thick), it features optional Epoxy Coating or Rubber Lining for superior corrosion resistance in municipal and seawater applications.

Product Description

Cost-Effective Solution for Mega-Scale Filtration.

For vessel diameters exceeding 1500mm, stainless steel becomes prohibitively expensive. The Stark STK2 Carbon Steel Series provides robust structural integrity at a fraction of the cost. With models ranging from Ø500mm up to a massive Ø3200mm, it handles flow rates up to 120 T/h per unit.

Anti-Corrosion Options:

1. Epoxy Coated: Economical choice for standard fresh water applications.

2. Rubber Lined (3-5mm): Premium protection for Seawater Desalination or abrasive sand filtration. The rubber layer effectively resists chloride corrosion and the physical abrasion of moving media.

Note: Price includes the pressure vessel only. External piping, valve manifolds, and media are sold separately.

Lining Specs & Spark Testing:

Quality assurance is critical for lined vessels. To view our rubber lining thickness standards, spark test reports (for pinholes), and detailed dimensional drawings, please reference the technical data at our manufacturing division:

Stark Manufacturing – Carbon Steel Vessel Specs

.

Product Parameter

Below are the specifications for our STK2 Carbon Steel series. Available with Epoxy or Rubber Lining.

| Model | Size (DxH) | Flow (T/h) | Thickness | Ref: Sand | Ref: Carbon | Ref: Resin | Action |

|---|---|---|---|---|---|---|---|

| MMFC-D500×1900 | Φ500×1220 | 2-3 | 3.0mm | 245kg | 80kg | 175L | Inquiry |

| MMFC-D1000×2500 | Φ1000×1500 | 8-12 | 4.0mm | 1200kg | 400kg | 800L | Inquiry |

| MMFC-D1500×2850 | Φ1500×1500 | 18-27 | 5.0mm | 2700kg | 900kg | 1775L | Inquiry |

| MMFC-D2000×3600 | Φ2000×1800 | 32-47 | 6.0mm | 5700kg | 1900kg | 3800L | Inquiry |

| MMFC-D2500×4000 | Φ2500×2000 | 49-74 | 8.0mm | 9900kg | 3300kg | 6575L | Inquiry |

| MMFC-D3200×5350 | Φ3200×2500 | 80-120 | 10.0mm | 20200kg | 6750kg | 13475L | Inquiry |

*Material: Q235B Carbon Steel. Options: Epoxy Coating or Rubber Lining. Standard design pressure 0.6-1.0 MPa.

Applicable Industry

- Seawater Desalination (SWRO):

Rubber-lined carbon steel vessels are the industry standard for SWRO pre-treatment, offering excellent resistance to high-salinity corrosion. - Municipal Water Treatment:

Cost-effective replacement for concrete sand filter pools. A single Ø3200mm vessel can handle 120 tons/hour, ideal for city water supply upgrades. - Large Industrial Cooling:

Robust side-stream filtration for power plants and steel mills, where durability and large flow capacity are paramount.

Advantage One

Advanced Corrosion Protection (Rubber Lining)

For harsh environments, paint isn’t enough. Our Rubber Lining Option involves bonding a 3-5mm layer of natural rubber to the interior.This lining provides dual protection: it is chemically inert to chlorides (seawater) and mechanically resilient, absorbing the impact of sand particles during backwashing to prevent abrasion.Advantage TWO

Massive Scale Engineering (Up to Ø3200mm)

We specialize in heavy-duty fabrication. Our flagship MMFC-D3200 model features a 3.2-meter diameter and 10mm wall thickness.Capable of processing 120,000 liters per hour, these mega-vessels reduce the footprint of your filtration plant by minimizing the number of tanks required.Related Products

Related products

- Stainless Steel Products

Sanitary Stainless Steel Multi-Cartridge Filter Housing – Quick-Open Clamp Series

Read more - Stainless Steel Products

Stainless Steel Mechanical Filter Housing – Multimedia Sand & Carbon Vessel

Read more

FAQ

Q1: How long does the reverse osmosis system last?

The lifespan of a reverse osmosis system depends on water quality and maintenance. Typically, the membrane lasts 2–3 years, while the system itself can last over 10 years with proper care.

Q2: Can the system be customized based on different water conditions?

Yes, all our systems are fully customizable. We analyze your water report and application needs before providing tailored solutions.

Q3: What standards does STARK equipment comply with?

Our products comply with CE, ISO 9001, and can be designed to meet specific regional regulations or industry standards upon request.

Q4: What is the delivery time for STARK RO systems?

Standard systems are shipped within 7–15 days. For customized orders, lead time may extend to 20–25 days depending on complexity.

Q5: Do you provide technical support or installation guidance?

Yes. We provide full technical documentation, remote guidance via video, and can dispatch engineers internationally upon request.

Q6: What is included in your quotation?

Our quotation includes the full RO system, control panel, pumps, pre-treatment units, and all necessary fittings. Installation tools and spare parts can be included upon request.