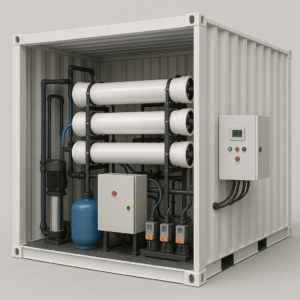

Dual-Stage Containerized RO System for High TDS and Critical Water Purification

Conquer complex water purification challenges with Stark Water’s Dual-Stage Containerized RO System. This advanced containerized reverse osmosis unit is engineered for high TDS and critical water purification, delivering ultra-pure water with rapid deployment and robust performance for demanding industrial and commercial applications globally.

Product Description

For industries facing extremely challenging water sources characterized by high Total Dissolved Solids (TDS) or requiring exceptionally stringent purity standards, conventional single-stage Reverse Osmosis (RO) systems may fall short. Furthermore, logistical demands for rapid deployment in remote or temporary locations necessitate self-contained solutions. The Stark Water Dual-Stage Containerized RO System is meticulously engineered to address these formidable challenges, providing a comprehensive and highly robust answer for high TDS and critical water purification.

Dual-Stage Containerized Reverse Osmosis: Unmatched Purity for High TDS Water

Our advanced containerized reverse osmosis system employs a dual-stage (double-pass) RO configuration, representing a significant leap in purification capability. While a single RO stage effectively removes the majority of contaminants, a second pass further refines the water, significantly reducing residual ions, increasing overall contaminant rejection, and producing water of exceptionally high purity. This dual-stage design is particularly vital for:

- High TDS Water: Effectively treating raw water sources with very high dissolved solids concentrations, ensuring the final permeate meets stringent purity requirements.

- Critical Water Purification: Achieving ultra-pure water quality levels required by sensitive industries where even trace impurities are unacceptable (e.g., electronics, pharmaceuticals, power generation).

- Enhanced Contaminant Removal: Providing an additional barrier against challenging impurities like silica, boron, and complex organics, which may not be fully removed in a single pass.

The entire system is pre-assembled, piped, wired, and tested within a standard shipping container, ensuring plug-and-play functionality and robust protection from harsh environmental conditions.

Rapid Deployment and Robust Protection for Industrial Applications

The containerized nature of this reverse osmosis system offers unparalleled advantages for various demanding industrial and commercial applications. Being fully self-contained, it allows for:

- Rapid Deployment: Systems are ready for immediate connection upon arrival, drastically reducing on-site installation time and costs, critical for emergency response or project acceleration.

- Mobility and Flexibility: Easily transported by road, rail, or sea, making it ideal for remote sites, temporary projects, disaster relief, or mobile operations.

- Protection from Elements: The container provides inherent protection from extreme weather, dust, and security risks, ensuring optimal operating conditions and extending equipment lifespan.

- Minimal Civil Works: Significantly reduces the need for costly and time-consuming civil construction, simplifying project logistics.

This robust integration makes the system highly reliable and durable, suitable for continuous operation in challenging industrial environments.

Comprehensive Integration for Uncompromising Water Quality

The Dual-Stage Containerized RO System integrates all necessary purification stages for high TDS and critical water purification. This typically includes advanced pre-treatment (multi-media filters, activated carbon, anti-scalant dosing, micron filters), the dual-stage RO modules, high-pressure pumps (often with energy recovery devices for large units), and an advanced PLC control system with HMI for fully automatic operation and real-time monitoring. Optional post-treatment (e.g., EDI, UV sterilization, remineralization) can also be integrated to achieve specific final water quality requirements. This comprehensive approach ensures consistently high-quality pure water, protects valuable downstream equipment, and contributes to sustainable water management through efficient resource utilization.

Product Parameter

Stark Water’s Dual-Stage Containerized RO System is engineered for robust, high-purity, and mobile water purification. Here are its key technical specifications:

| Parameter | Specification / Customization Options |

|---|---|

| Core Keyword Focus | containerized reverse osmosis design and capabilities. |

| System Configuration | Dual-Stage (Double-Pass) Reverse Osmosis (RO) System. Custom capacities available. |

| Pure Water Capacity | Customizable, ranging from 1 m³/hr to 200+ m³/hr (approx. 4.4 GPM to 880+ GPM). Multi-container solutions for larger capacities. |

| Raw Water Source Compatibility | Highly versatile for Brackish Water (TDS up to 15,000 ppm), or Seawater (TDS up to 45,000 ppm) with appropriate pre-treatment. Designed for High TDS and Critical Water Purification. |

| RO Membrane Type | High-rejection Thin-Film Composite (TFC) RO Membranes (e.g., 8040 series), specifically selected for high TDS/dual-stage applications (e.g., SWRO or BWRO membranes). |

| Overall Salt Rejection Rate | ≥99.8% – 99.9% (after second stage RO, for very high purity). |

| Output Water Quality | Very low TDS, high resistivity, significantly reduced silica, boron, and trace contaminants. Meets stringent industrial specifications for critical applications. Meets WHO drinking water standards (if applicable). |

| Water Recovery Rate | 40% – 75% (BWRO); 30% – 50% (SWRO). Optimized for specific raw water and energy efficiency. |

| High-Pressure Pumps | Heavy-duty, energy-efficient, corrosion-resistant pumps for both RO stages (often with VFDs). |

| Pre-treatment System |

Designed for high TDS or specific challenging raw water characteristics. |

| Post-treatment (Optional) | EDI, UV Sterilization, Remineralization, Degasification. Integrated based on final water quality requirements. |

| Container Type | Standard ISO Shipping Container (e.g., 20ft, 40ft, High Cube). Custom modifications for access, insulation, HVAC. |

| Control System | Advanced Fully Automatic PLC Control with HMI. Comprehensive monitoring of multiple RO stages, CIP, alarms. Remote monitoring/SCADA integration. |

| Power Supply | 3 Phase, 380V/415V/460V, 50Hz/60Hz (Customizable). Integrated power distribution. |

| Construction Material |

|

| Deployment | Designed for rapid transport and plug-and-play installation. |

| Certification | Designed to meet relevant international standards (e.g., ISO, CE, ASME, FDA/GMP where applicable). |

Applicable Industry

Stark Water’s Dual-Stage Containerized RO System is a highly specialized and indispensable solution for industries and sectors requiring exceptionally pure water from challenging high TDS sources, with demands for rapid deployment and robust operation. Its capabilities make it ideal for:

- Oil & Gas Industry (Onshore/Offshore): Providing high-purity water for drilling, fracking, steam injection, and camp water supply, often from brackish or produced water sources in remote locations.

- Mining & Metals Industry: For treating highly mineralized process water or wastewater, achieving high purity for reuse or environmental discharge in remote mining sites.

- Pharmaceutical & Biotechnology (Remote/Temporary): Supplying high-purity water for certain manufacturing processes or pilot plants where stringent quality (e.g., PW) is required in flexible locations.

- Power Generation (Remote/Temporary): Providing high-purity boiler feed water or cooling water for power plants in remote areas or for temporary energy projects, often treating high TDS sources.

- Emergency & Disaster Relief: Rapid deployment of ultra-pure water production for critical needs in crisis zones, capable of treating challenging raw water.

- Military & Humanitarian Operations: Supplying high-ppurity potable and utility water in various operational theaters or remote camps.

- Coastal Communities & Island Nations (High Salinity/Critical Use): Providing ultra-pure drinking water or process water from very high salinity seawater, where standard SWRO is insufficient for final purity.

- Chemical Manufacturing (Specialty): For producing very high purity water for sensitive chemical reactions or dilutions, where specific trace contaminants from high TDS sources must be removed.

- Electronics & Semiconductor Manufacturing (Auxiliary/Remote): Providing high-purity water for specific process lines or remote fabrication sites.

- Large-Scale Agricultural & Hydroponic Projects: Treating high TDS water for precise nutrient solutions where ultra-purity is crucial.

Advantage One

Stark Water’s Dual-Stage Containerized RO System offers the significant advantage of ultimate purity for high TDS water via dual-stage RO filtration. This advanced containerized reverse osmosis unit employs a double-pass RO configuration that meticulously purifies even the most challenging raw water sources with high Total Dissolved Solids. The two sequential RO stages effectively reduce residual ions, silica, boron, and other difficult-to-remove contaminants to exceptionally low levels, producing water of ultra-pure quality. This unparalleled purification capability is critical for sensitive industrial applications like electronics, pharmaceuticals, and power generation, where even trace impurities are unacceptable, ensuring product integrity, preventing equipment fouling, and meeting the most stringent water quality specifications.

Advantage TWO

Our Dual-Stage Containerized RO System provides the dual advantage of rapid deployment and robust performance in a fully containerized solution. As a complete containerized reverse osmosis unit, it is factory-assembled, pre-tested, and ready for immediate plug-and-play operation upon arrival, drastically minimizing on-site installation time and costs. The rugged container provides inherent protection from harsh environmental conditions, making it ideal for remote, temporary, or mobile industrial applications. This robust design, combined with the advanced purification capabilities of dual-stage RO for high TDS and critical water purification, ensures consistent, high-quality pure water production with unparalleled reliability and operational flexibility, even in the most demanding and challenging locations globally.

Related Products

Related products

- Container reverse osmosis system

40FT Containerized RO System for Industrial and Export Water Treatment Projects

Read more - Container reverse osmosis system

20FT Containerized RO System for Compact and Mobile Water Treatment

Read more - Container reverse osmosis system

STARK industrial Containerized RO Purification Systems Containerized Chemical Water Reverse Osmosis System

Read more

FAQ

Q1: How long does the reverse osmosis system last?

The lifespan of a reverse osmosis system depends on water quality and maintenance. Typically, the membrane lasts 2–3 years, while the system itself can last over 10 years with proper care.

Q2: Can the system be customized based on different water conditions?

Yes, all our systems are fully customizable. We analyze your water report and application needs before providing tailored solutions.

Q3: What standards does STARK equipment comply with?

Our products comply with CE, ISO 9001, and can be designed to meet specific regional regulations or industry standards upon request.

Q4: What is the delivery time for STARK RO systems?

Standard systems are shipped within 7–15 days. For customized orders, lead time may extend to 20–25 days depending on complexity.

Q5: Do you provide technical support or installation guidance?

Yes. We provide full technical documentation, remote guidance via video, and can dispatch engineers internationally upon request.

Q6: What is included in your quotation?

Our quotation includes the full RO system, control panel, pumps, pre-treatment units, and all necessary fittings. Installation tools and spare parts can be included upon request.