Stark LP-4040 Industrial RO Membrane Element (High Flux 5L/min, 99.2% Rejection)

- Model: STK-LP4040 (Polyamide Composite Material)

- High Performance: 99.2% Salt Rejection with 5L/min High Flux.

- Energy Efficient: Operates at low pressure (0.9 MPa / 130 psi) to reduce energy costs.

- Stock Status: In Stock. 100 units available for immediate shipping.

- Special Offer: Bulk discount applies for orders of 10+ units.

Product Description

Stark High-Efficiency LP-4040 Industrial RO Membrane

The Stark STK-LP4040 is a “Low Pressure” (LP) series aromatic polyamide compound membrane element designed for commercial and industrial water treatment applications. It is engineered to deliver high permeate flow while operating at lower pressures, significantly reducing energy consumption and pump operating costs.

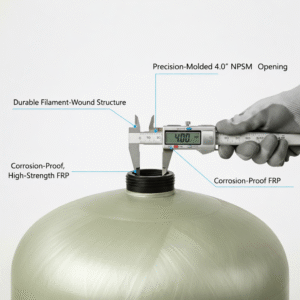

This standard 4-inch membrane element (4″ x 40″) is a universal fit for glass fiber or stainless steel pressure vessels, making it an ideal drop-in replacement for existing RO systems.

Key Features and Benefits

- Superior Salt Rejection: With an average rejection rate of 99.2%, it effectively removes dissolved salts, organics, and bacteria, ensuring high-quality permeate water.

- High Flux Output: Producing up to 5L/min (approx. 1900 GPD), this membrane maximizes water production efficiency.

- Energy Saving Design: Operates efficiently at a low testing pressure of 0.9 MPa (approx. 130 psi), lowering the load on high-pressure pumps compared to standard membranes.

- Durable Structure: Features a robust 7.8 m² effective membrane area with a 31mil-pp feed spacer to minimize fouling.

Stock Alert: Immediate Dispatch Available

We currently have a spot inventory of 100 units ready to ship. This batch allows for zero lead time, helping you avoid costly system downtime.

Bulk Discount: Contact our sales team for exclusive pricing on orders of 10 units or more.

Product Parameter

| Model | LP-4040 |

| Membrane Material | Polyamide Composite Material |

| Dimensions | Length: 1016mm (40″) | Diameter: 100mm (4″) |

| Effective Area | 7.8 m² |

| Average Permeate Flow | 5L/MIN (~1900 GPD) |

| Stable Rejection Rate | 99.2% (Min 99.0%) |

| Test Pressure | 0.9 MPa |

| pH Range | Operating: 3-10 | Cleaning: 2-11 |

| Feed Water Max Temp | 45°C |

*Test Conditions: 1000ppm NaCl solution, 25°C temperature, pH 7.5, and 20% recovery rate. Performance may vary ±15%.

Applicable Industry

The Stark LP-4040 is a versatile industrial component designed for a wide range of commercial and light industrial water treatment scenarios. Its balance of high flow and low energy consumption makes it the ideal choice for:

- Commercial Spot-Free Car Wash Systems:Produces ultra-pure water with low Total Dissolved Solids (TDS), ensuring a spot-free rinse finish for vehicles without the need for manual drying.

- Water Vending Machines & Kiosks:The high flow rate (5L/min) ensures rapid tank filling, allowing machines to serve more customers efficiently while maintaining fresh, great-tasting water.

- Laboratory & Hospital Water Purification:Acts as the primary pre-treatment stage for ultrapure water systems, effectively removing bacteria, pyrogens, and inorganic ions to meet strict clinical standards.

- Food & Beverage Production:Provides consistent, high-quality ingredient water for bottling plants, breweries, and coffee shops, ensuring that the taste of the final product remains pure and unaltered.

- Light Industrial Boiler Feed:Removes hardness and silica from feed water to prevent scaling in low-pressure boilers, significantly improving thermal efficiency and preventing pipe blockages.

- Hydroponics & Agriculture:Filters out harmful heavy metals and excess salts from well water, creating a nutrient-neutral base perfect for mixing custom fertilizer solutions.

Advantage One

Ultra-Low Pressure Operation for Maximum Energy Savings

The Stark STK-LP4040 is engineered with advanced “Low Pressure” (LP) polyamide composite technology. Unlike standard RO membranes that require high operating pressures, this model achieves optimal performance at just 0.9 MPa (approx. 130 psi).Why is this a major advantage?- Reduced Electricity Costs: Lower operating pressure means your high-pressure pumps don’t have to work as hard, significantly cutting down energy consumption by up to 30% compared to standard membranes.

- Extended Equipment Lifespan: Lower pressure puts less stress on pumps, pipes, fittings, and O-rings. This reduces the risk of leaks and mechanical failures, leading to lower maintenance costs over the system’s life.

- Cost-Effective Upgrade: It allows system integrators to use smaller, more affordable pumps for new installations without sacrificing water production volume.

Advantage TWO

Superior Permeate Quality with High Flux Technology

Productivity matters. The Stark LP-4040 features an optimized effective membrane area of 7.8 m², delivering a massive permeate flow rate of 5L/min (approx. 1900 GPD). This “High Flux” capability ensures you get more purified water in less time.Uncompromised Purity:- 99.2% Salt Rejection Rate: Utilizing a dense polyamide active layer, it effectively blocks dissolved salts, heavy metals, organics, and colloidal particles.

- Stable Performance: Even with variable feed water qualities (up to 1000ppm concentration), it maintains a minimum salt rejection of 99.0%, ensuring the safety and conductivity standards of your output water.

- Fouling Resistance: The smooth surface structure and 31mil feed spacer design help reduce the accumulation of contaminants, extending the cleaning cycle (CIP) intervals.

Related Products

Related products

FAQ

Q1: How long does the reverse osmosis system last?

The lifespan of a reverse osmosis system depends on water quality and maintenance. Typically, the membrane lasts 2–3 years, while the system itself can last over 10 years with proper care.

Q2: Can the system be customized based on different water conditions?

Yes, all our systems are fully customizable. We analyze your water report and application needs before providing tailored solutions.

Q3: What standards does STARK equipment comply with?

Our products comply with CE, ISO 9001, and can be designed to meet specific regional regulations or industry standards upon request.

Q4: What is the delivery time for STARK RO systems?

Standard systems are shipped within 7–15 days. For customized orders, lead time may extend to 20–25 days depending on complexity.

Q5: Do you provide technical support or installation guidance?

Yes. We provide full technical documentation, remote guidance via video, and can dispatch engineers internationally upon request.

Q6: What is included in your quotation?

Our quotation includes the full RO system, control panel, pumps, pre-treatment units, and all necessary fittings. Installation tools and spare parts can be included upon request.