Plastic & Acrylic Flow Meter (Rotameter) | Stark Water

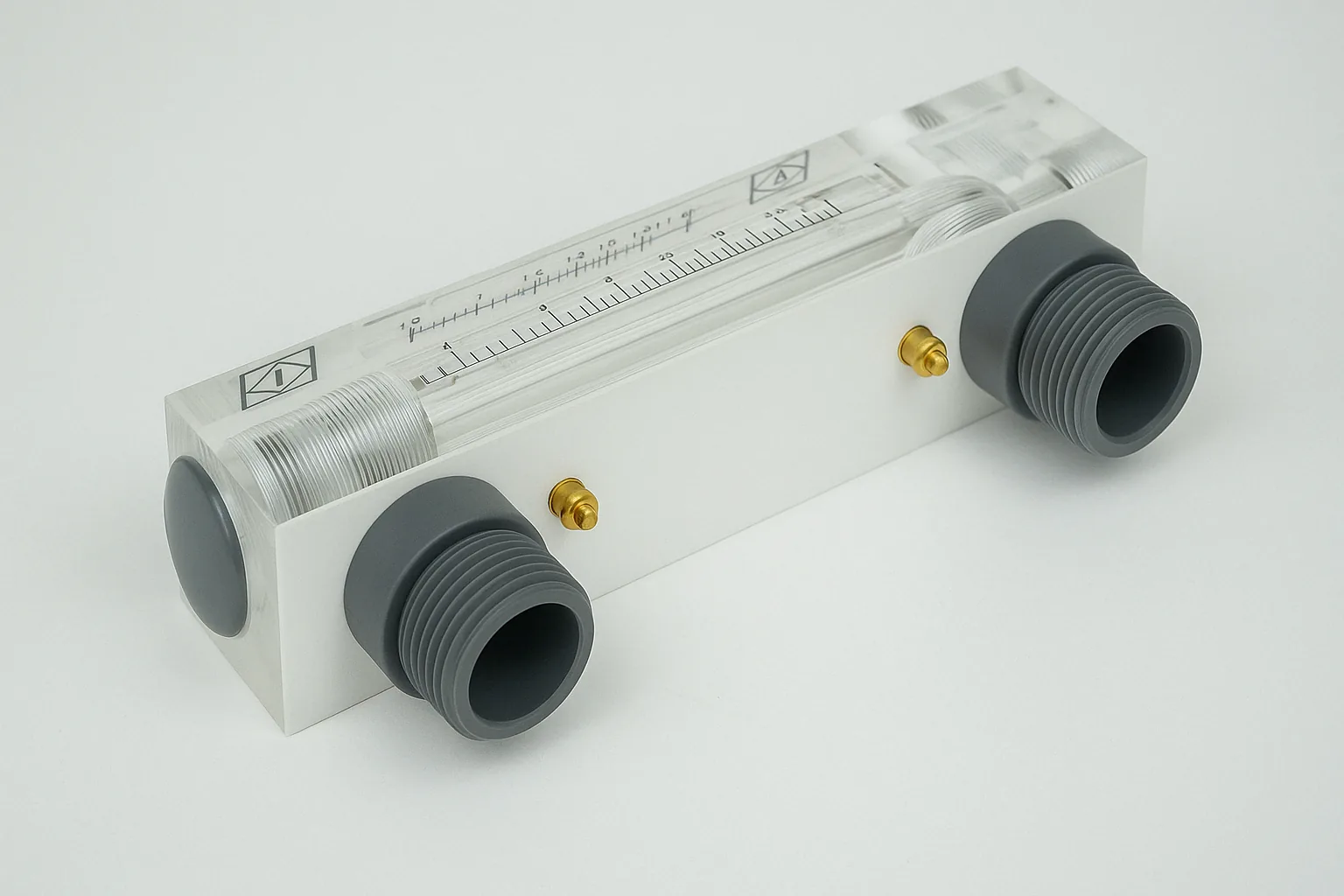

Plastic acrylic flow meter (rotameter) by STARK provides clear, accurate indication of water and air flow for RO skids, dosing lines, and HVAC loops.

Product Description

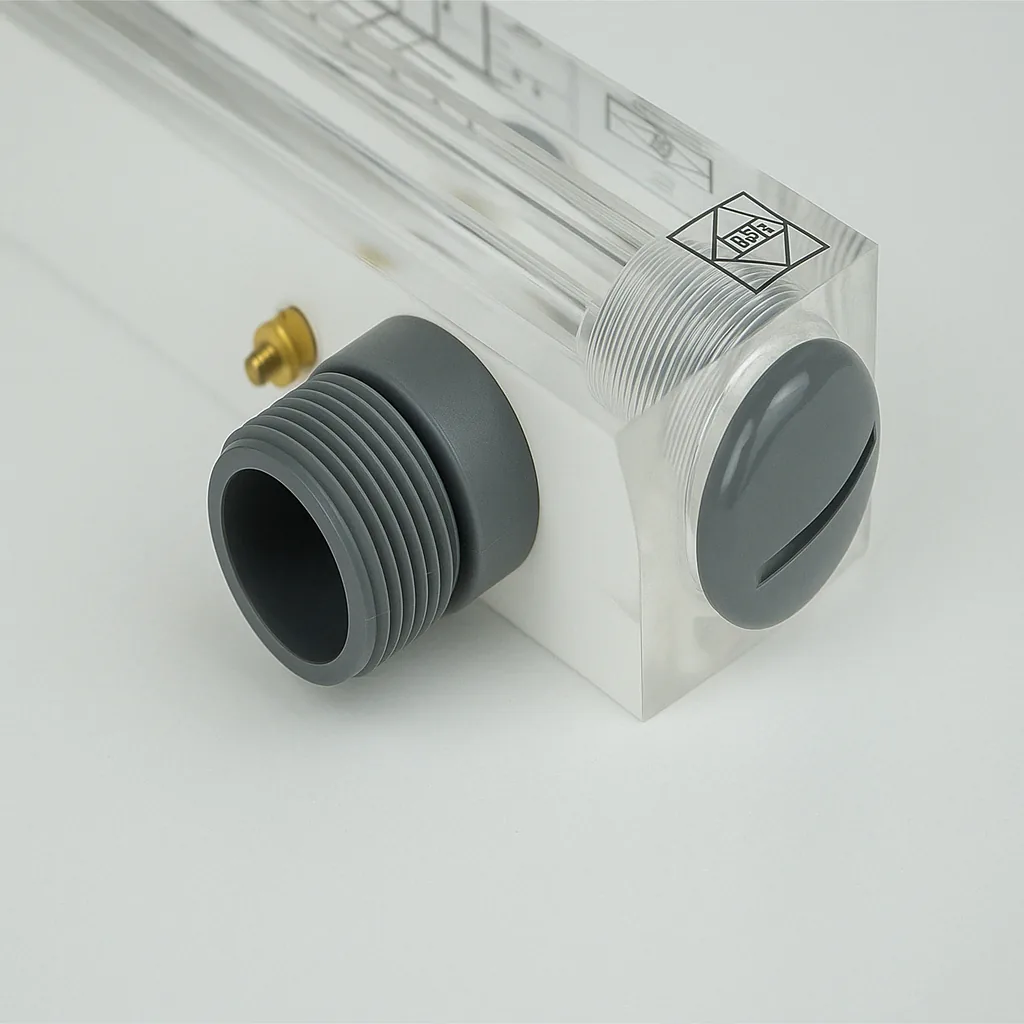

Standard bodies are PVC or PP with a clear acrylic tube for excellent readability and impact resistance. Units include stainless-steel or optional plastic floats (range-dependent), O-ring seals, and union end connections for quick installation and service. Calibration can be supplied in L/h, L/min, m³/h or GPM to suit project specifications.

- Clean scale printing with protective window; optional dual-scale (water/air)

- Compact form factor for panel or in-line mounting

- Good chemical compatibility for typical water-treatment fluids

- Each unit tested for leakage and scale accuracy before shipment

Product Parameter

| Measurement Principle | Variable area (rotameter) with float in tapered acrylic tube |

|---|---|

| Media | Water or air (other compatible liquids/gases on request) |

| Body / Tube | PVC or PP body; clear acrylic tube |

| Float | Stainless steel / PTFE / PVC (per flow range) |

| Seals | EPDM standard; FKM (Viton) optional |

| Nominal Sizes | DN15–DN50 (1/2″–2″) typical; others on request |

| Connections | Union/threaded or solvent-weld; BSP/NPT available |

| Flow Ranges (water @20 °C) | Approx. 10–100 L/h up to 1–10 m³/h (model-dependent) |

| Accuracy | ±4% of full scale (typical rotameter accuracy) |

| Max Pressure | 0.6–1.0 MPa depending on size and material |

| Max Temperature | 0–60 °C (consult STARK for higher or chemical service) |

| Mounting | Vertical installation, flow from bottom to top |

| Compliance | Manufactured under STARK QA; pressure/leak tested |

Note: Final BOM (tube length, float material, scale units, and end connections) will be confirmed after your process data sheet is reviewed.

Applicable Industry

- Reverse osmosis skids — permeate and concentrate monitoring

- Sand/carbon filters — backwash and rinse flow checks

- Chemical dosing systems — coagulant/antiscalant lines

- Cooling water & HVAC loops — visual flow confirmation

- Compressed air distribution — branch line balancing

- Laboratory & pilot plants — quick setup and verification

Advantage One

Advantage 1 — Clear, Reliable Indication

- High-clarity acrylic tube with printed scale and reference pointer

- Simple mechanical design — no power supply required

- Union ends for fast installation and maintenance

- Multiple scale options (L/h, L/min, m³/h, GPM) and custom logo

Advantage TWO

Advantage 2 — Robust Materials & Support

- PVC/PP body and corrosion-resistant wetted parts

- EPDM or FKM seals to match your chemical conditions

- Factory leakage/accuracy testing and spare parts availability

- Global technical support and fast lead time from STARK

Related Products

Related products

- Water Treatment Accessories

Stainless Steel RO Membrane Housing – 8″ Side Entry Series (300 PSI)

Read more

FAQ

Q1: How long does the reverse osmosis system last?

The lifespan of a reverse osmosis system depends on water quality and maintenance. Typically, the membrane lasts 2–3 years, while the system itself can last over 10 years with proper care.

Q2: Can the system be customized based on different water conditions?

Yes, all our systems are fully customizable. We analyze your water report and application needs before providing tailored solutions.

Q3: What standards does STARK equipment comply with?

Our products comply with CE, ISO 9001, and can be designed to meet specific regional regulations or industry standards upon request.

Q4: What is the delivery time for STARK RO systems?

Standard systems are shipped within 7–15 days. For customized orders, lead time may extend to 20–25 days depending on complexity.

Q5: Do you provide technical support or installation guidance?

Yes. We provide full technical documentation, remote guidance via video, and can dispatch engineers internationally upon request.

Q6: What is included in your quotation?

Our quotation includes the full RO system, control panel, pumps, pre-treatment units, and all necessary fittings. Installation tools and spare parts can be included upon request.