Marine Reverse Osmosis System 20 m³/d | Shipboard Freshwater | STARK Water

Reverse osmosis ship system for reliable onboard freshwater: a compact marine RO skid delivering 20 m³/day, built with 316L/duplex wetted parts, PLC control, auto-flush and lay-up modes. Class-friendly documentation (GA, P&ID, IOM, FAT) and global spares ensure smooth installation and service at sea.

Product Description

Shipboard Reverse Osmosis for Reliable Freshwater at Sea

Designed for engine-room conditions, the STARK Marine RO converts seawater into potable water with lower energy use and faster start/stop than traditional evaporators. The skid integrates pre-filtration, high-pressure pumping, RO membranes and remineralization, with online conductivity and ΔP monitoring to keep OPEX predictable.

Why choose Marine RO over evaporators

Lower energy & heat load in the engine room

Compact footprint and modular expansion (parallel skids)

Simpler maintenance with standard filters and CIP ports

Better water quality control with continuous TDS monitoring

Marine-grade construction

Materials: 316L or duplex 2205/2507 options, A4 fasteners

Controls: PLC + HMI, auto-flush, alarms, optional VFD

Protection: IP54/IP55 electricals, anti-vibration mounts, corrosion-resistant coating

Docs: GA drawings, nozzle plan, P&ID, IOM, FAT/SAT templates for class compliance

Operations & OPEX

Auto-flush and lay-up routines minimize fouling during port stays or off-season. Typical specific energy: 3.5–5.5 kWh/m³ (temperature and recovery dependent). Consumables (cartridge filters, antiscalant) are standard marine supplies; membranes are compatible with major brands.

Note: Capacities and energy values vary with seawater temperature, TDS and recovery setpoint. Contact us for sizing based on crew number and route.

Product Parameter

| Parameter | Value |

|---|---|

| Permeate capacity | 20 m³/day @ 25°C, 35,000 mg/L TDS |

| Recovery range | 30–45% (temperature & fouling dependent) |

| Specific energy | 3.5–5.5 kWh/m³ (typical) |

| Membrane configuration | 8040 SWRO × 4 (DuPont/Toray compatible) |

| HP pump | SS316/duplex, optional VFD |

| Piping & frame | 316L standard, duplex option; marine coating |

| Instrumentation | Conductivity, pressure, ΔP, flow, temperature |

| Controls | PLC + HMI, auto-flush, alarms, lay-up mode |

| Electrical | 380–440 V, 50/60 Hz, 3-phase |

| Protection | IP54 / IP55 |

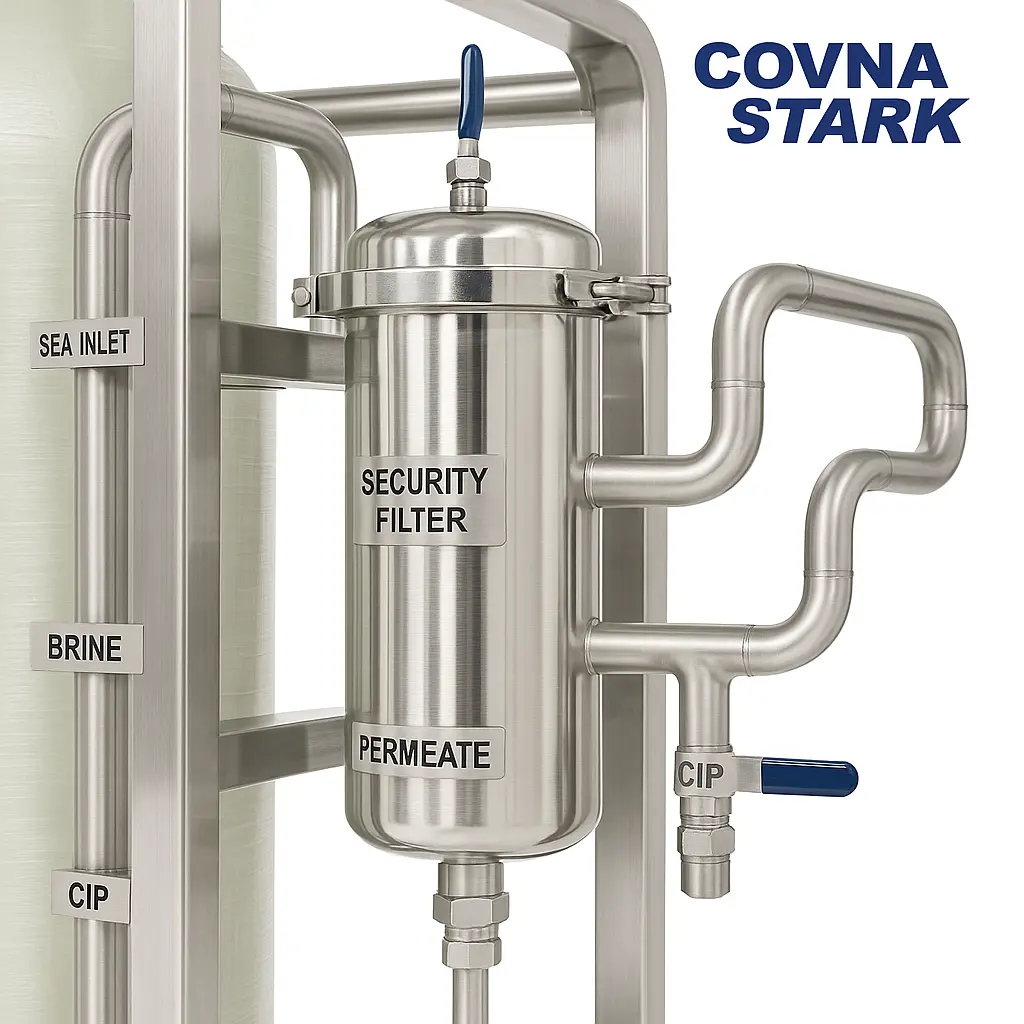

| Connections | Seawater inlet / brine / permeate / CIP ports |

| Footprint (L×W×H) | ~1800 × 900 × 1700 mm |

| Weight | ~650 kg |

| Documentation | GA, P&ID, IOM, FAT (class-friendly) |

| Options | Duplex materials, UV/chlorination, remineralization |

Applicable Industry

Marine vessels: cargo ships, OSVs, trawlers, ferries & Ro-Ro, patrol boats, cruise & expedition vessels

Offshore assets: platforms, barges, near-shore construction

Retrofit/Upgrade: evaporator replacement, redundancy skids, seasonal routes with variable intake quality

Advantage One

Advantage 1 — Lower Energy & Easier Operation

Replaces evaporators to cut energy and heat load

Fast start/stop, auto-flush and lay-up for port stays

Online monitoring (TDS/ΔP) keeps water quality and OPEX under control

Modular (N+1) design for redundancy and maintenance windows

Advantage TWO

Advantage 2 — Built for Marine Duty

316L/duplex wetted parts, anti-vibration mounts, marine coating

IP54/55 electrics, PLC + HMI with alarms and event logs

Class-friendly documentation for smooth approval and acceptance

Global spares & remote support to minimize downtime

Related Products

Related products

- Reverse osmosis system

STK-9T RO System Water Treatment Machine Commercial Reverse Osmosis System

Read more - Reverse osmosis system

1000L reverse osmosis system water desalination purification water treatment plant

Read more

FAQ

Q1: How long does the reverse osmosis system last?

The lifespan of a reverse osmosis system depends on water quality and maintenance. Typically, the membrane lasts 2–3 years, while the system itself can last over 10 years with proper care.

Q2: Can the system be customized based on different water conditions?

Yes, all our systems are fully customizable. We analyze your water report and application needs before providing tailored solutions.

Q3: What standards does STARK equipment comply with?

Our products comply with CE, ISO 9001, and can be designed to meet specific regional regulations or industry standards upon request.

Q4: What is the delivery time for STARK RO systems?

Standard systems are shipped within 7–15 days. For customized orders, lead time may extend to 20–25 days depending on complexity.

Q5: Do you provide technical support or installation guidance?

Yes. We provide full technical documentation, remote guidance via video, and can dispatch engineers internationally upon request.

Q6: What is included in your quotation?

Our quotation includes the full RO system, control panel, pumps, pre-treatment units, and all necessary fittings. Installation tools and spare parts can be included upon request.