Stark 500LPH reverse osmosis pretreatment water filter system

Optimize your Reverse Osmosis system’s performance and lifespan with Stark Water’s 500LPH Reverse Osmosis Pretreatment Water Filter System. This comprehensive pretreatment water filter system efficiently removes sediment, chlorine, and hardness, safeguarding your RO membranes and ensuring consistent pure water output for commercial and industrial applications.

Product Description

The longevity and efficiency of any Reverse Osmosis (RO) system are fundamentally dependent on the quality of its feed water. Without proper pre-treatment, RO membranes can quickly foul, scale, or become damaged, leading to costly downtime, frequent replacements, and diminished performance. The Stark Water 500LPH Reverse Osmosis Pretreatment Water Filter System is meticulously engineered to serve as the vital first line of defense, providing comprehensive and reliable conditioning for your RO feedwater.

The Critical Role of a Pretreatment Water Filter System for RO

Our 500LPH reverse osmosis pretreatment water filter system is specifically designed to prepare raw water for the delicate RO membranes. With a capacity of 500 liters per hour, it is ideally suited for small to medium-sized commercial and industrial RO plants. The primary goal of this pretreatment water filter system is to remove contaminants that could otherwise harm the RO membranes. These typically include:

- Suspended Solids & Turbidity: Particles like sand, silt, and rust can physically abrade or clog membrane surfaces.

- Chlorine & Chloramines: These disinfectants can chemically oxidize and irreversibly damage thin-film composite (TFC) RO membranes.

- Hardness (Calcium & Magnesium): These minerals precipitate as scale on the membrane surface, severely reducing water flow and rejection rates.

- Iron & Manganese: Can cause fouling and staining of membranes.

- Organic Matter: Can lead to biological fouling or accumulation on the membrane.

By effectively tackling these issues upstream, our system ensures the RO membranes operate under optimal conditions, maximizing their efficiency and greatly extending their operational lifespan.

Comprehensive Multi-Stage Filtration and Conditioning

The STARK 500LPH reverse osmosis pretreatment water filter system typically incorporates a series of interconnected stages to provide thorough water conditioning:

- Multi-Media Filtration: Often includes sand filters or multimedia filters to effectively remove larger suspended solids, turbidity, and sediment.

- Activated Carbon Filtration: Essential for removing free chlorine, chloramines, organic compounds, unpleasant tastes, and odors, protecting the RO membranes from chemical oxidation.

- Water Softening (Ion Exchange): If the raw water has significant hardness, an automatic water softener is integrated to remove calcium and magnesium ions, preventing scale formation on the RO membranes.

- Anti-scalant Dosing: A chemical dosing system may be included to inject anti-scalant, further inhibiting scale precipitation on the membrane surface, especially for challenging water chemistries or high recovery rates.

- Micron Cartridge Filtration: A final safety filter (e.g., 5-micron) removes any residual fine particulates that might have passed through previous stages, providing absolute protection for the RO membranes.

This integrated approach ensures robust protection and optimal performance for your downstream RO system, translating into consistent pure water output and reduced operational costs.

Product Parameter

Stark Water’s 500LPH Reverse Osmosis Pretreatment Water Filter System is engineered for efficient and reliable RO feedwater conditioning. Here are its key technical specifications:

| Parameter | Specification / Customization Options |

|---|---|

| Core Keyword Focus | pretreatment water filter system design and capabilities. |

| System Capacity | 500 Liters Per Hour (LPH) / 0.5 m³/hr / approx. 2.2 GPM. Customizable for other capacities. |

| Application | Pre-treatment for Reverse Osmosis (RO) systems. |

| Typical Stages Included |

|

| Filter Tanks Material | FRP (Fiber Reinforced Plastic) or Carbon Steel (lined) for larger units. |

| Control Type | Automatic control valves (time-based or flow-based for filters/softeners) for backwash/regeneration. PLC control for comprehensive system automation. |

| Inlet Water Requirements | Municipal Water, Well Water, Brackish Water (pre-filtration for various RO types). |

| Output Water Quality (to RO) | SDI (Silt Density Index) < 3; Free Chlorine < 0.1 ppm; Hardness < 0.03 mg/L (as CaCO³ if softener is included); Turbidity < 1.0 NTU. |

| Operating Pressure | Typically 0.2 – 0.6 MPa (2 – 6 Bar / 29 – 87 PSI). |

| Operating Temperature | 5°C – 45°C (41°F – 113°F). |

| Power Supply | Single Phase 220V AC, 50/60Hz or 3 Phase 380V AC, 50/60Hz (for automatic valves, pumps, dosing systems). |

| Construction Materials (Piping) | UPVC, HDPE, or Stainless Steel. |

| Dimensions (Approximate) | Skid-mounted compact design (e.g., L 1500mm x W 700mm x H 1800mm for a typical 500LPH system). |

| Certification | Designed to meet relevant industry standards. |

Applicable Industry

Stark Water’s 500LPH Reverse Osmosis Pretreatment Water Filter System is a versatile and essential component for industrial and commercial sectors utilizing RO technology, where effective feedwater conditioning is critical. This pretreatment water filter system is ideal for:

- Commercial & Industrial RO Systems (Small-to-Medium Scale): Providing comprehensive pre-treatment for RO plants used in bottled water production, beverage formulation, food processing, and general industrial process water.

- Hotels & Resorts: Ensuring optimal performance and longevity of RO systems used for drinking water, laundry, and general utility water supply.

- Laboratories & Research Facilities: Pre-treating water for RO systems that supply high-purity water for various lab operations and analytical instruments.

- Hospitals & Clinics: Preparing water for RO systems used in laundries, kitchens, or non-critical applications where high-quality feedwater protects downstream equipment.

- Schools & Educational Institutions: Pre-treating water for RO systems that provide purified drinking water for students and staff.

- Boiler Feed Water Pre-treatment: Conditioning raw water before it enters RO systems, which then feed low to medium pressure boilers, preventing scaling and corrosion.

- Cooling Tower Make-up Water: Pre-filtering water for RO systems used to treat make-up water for cooling towers, reducing mineral buildup and minimizing blowdown.

- Car Washes & Vehicle Detailing: Pre-treating water for RO systems that produce spot-free rinse water, extending the life of RO membranes.

- Agricultural & Horticultural (Specialized): Preparing water for RO systems used in hydroponics or specialized irrigation where precise water quality is essential.

- Small-Scale Manufacturing: Pre-filtering water for RO systems used in specific production processes requiring purified water.

Advantage One

Advantage TWO

Related Products

Related products

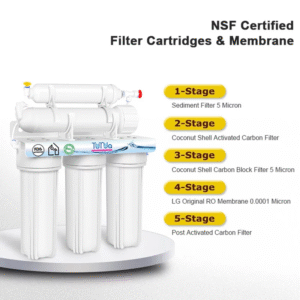

- Household water purifier

75GPD Reverse Osmosis Household Water Purifier | 5-Stage Water Filter Purifier

Read more

FAQ

Q1: How long does the reverse osmosis system last?

The lifespan of a reverse osmosis system depends on water quality and maintenance. Typically, the membrane lasts 2–3 years, while the system itself can last over 10 years with proper care.

Q2: Can the system be customized based on different water conditions?

Yes, all our systems are fully customizable. We analyze your water report and application needs before providing tailored solutions.

Q3: What standards does STARK equipment comply with?

Our products comply with CE, ISO 9001, and can be designed to meet specific regional regulations or industry standards upon request.

Q4: What is the delivery time for STARK RO systems?

Standard systems are shipped within 7–15 days. For customized orders, lead time may extend to 20–25 days depending on complexity.

Q5: Do you provide technical support or installation guidance?

Yes. We provide full technical documentation, remote guidance via video, and can dispatch engineers internationally upon request.

Q6: What is included in your quotation?

Our quotation includes the full RO system, control panel, pumps, pre-treatment units, and all necessary fittings. Installation tools and spare parts can be included upon request.