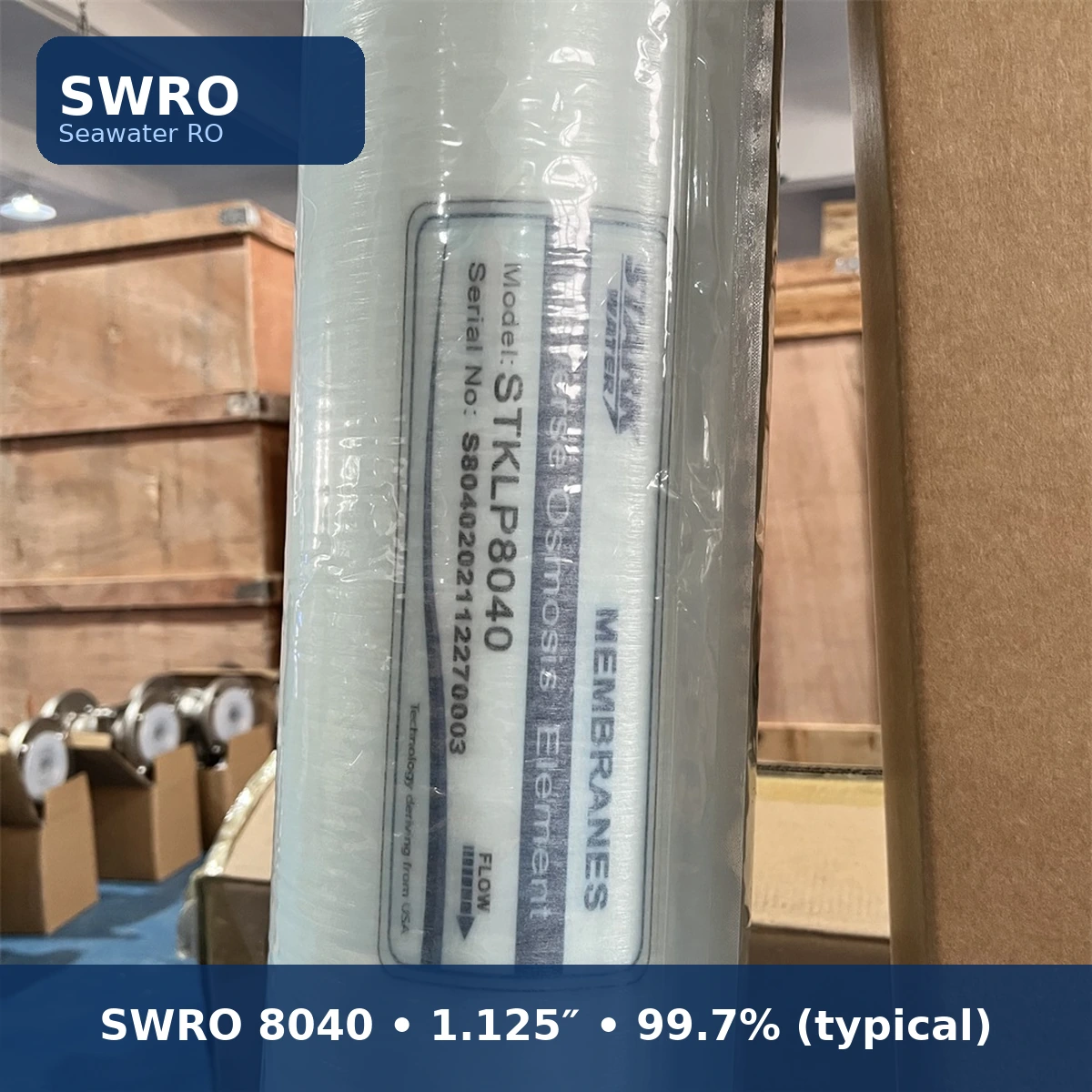

SWRO 8040 High Rejection RO Membrane

SWRO 8040 high-rejection seawater reverse osmosis membrane for first-pass desalination. Rated around 32,000 mg/L NaCl at 25 °C with typical operating pressure near 800 psi. Typical salt rejection up to 99.7% when pretreatment, recovery, and temperature follow supplier limits.

Product Description

This SWRO 8040 RO membrane is engineered for first-pass seawater desalination, combining high salt rejection with stable flux under standard SWRO test conditions.

This 8.0″ × 40″ thin-film composite (TFC) RO membrane is built for industrial and municipal seawater lines that need high rejection, predictable flux, and compatibility with standard 8040 pressure vessels and interconnectors. It integrates cleanability and preservation guidance so operators can maintain stable product water over the service life.

Key features

- High salt rejection (typical up to 99.7%) for low product conductivity.

- Optimized feed spacer for stable differential pressure and cleaning recovery.

- 1.125″ permeate tube ID; drop-in fit for standard 8040 vessels and couplers.

- Works with staged arrays and energy recovery devices in SWRO trains.

- Supported by approved CIP chemistry and preservation procedures.

Interfaces & compatibility

- Format: 8040 TFC polyamide element

- Permeate tube: 1.125″ (28.6 mm)

- Vessels/couplers: standard 8″ multi-element pressure vessels with interconnectors

- Change-out: replace like-for-like in most 8040 housings

Operating & cleaning limits*

- Max temperature: 45 °C (113 °F)

- pH range (operation): 2–11; (cleaning): 1–12

- Max pressure: 1,200 psi (8.3 MPa)

- Free chlorine: not recommended on TFC unless the datasheet explicitly allows; dechlorinate upstream

*Always verify the exact limits on the current model datasheet.

Typical test conditions

32,000 mg/L NaCl, 25 °C, ~800 psi, ~8% recovery. In service, performance varies with temperature, salinity, recovery, and pretreatment (SDI/MFI, antiscalant window).

What’s included and Why choose this SWRO 8040 RO membrane

- Factory-preserved element in sealed bag

- Installation & torque notes; cleaning/preservation guidance (download)

Need field criteria? See RO membrane replacement, cleaning & CIP, and troubleshooting matrix.

Product Parameter

| Element size | 8.0″ × 40″ (8040) |

|---|---|

| Active area | ~37 m² (400 ft²), model dependent |

| Typical salt rejection | up to 99.7% (datasheet dependent) |

| Rated permeate flow (window) | ~28–34 m³/d (7,500–9,000 gpd) @ 32,000 mg/L, 25 °C |

| Permeate tube ID | 1.125″ (28.6 mm) |

| Max operating pressure | 1,200 psi (8.3 MPa) |

| Max temperature | 45 °C (113 °F) |

| pH range | 2–11 operation; 1–12 cleaning |

| Test conditions | 32,000 mg/L NaCl; 25 °C; ~800 psi; ~8% recovery |

Values shown are typical for listing purposes; final selection should follow the current model datasheet.For most retrofits, this swro 8040 ro membrane drops into standard 8″ vessels with 1.125″ permeate tubes.

Applicable Industry

- Seawater desalination (first-pass SWRO) for municipalities

- Coastal hotels, island resorts, marine/offshore watermakers

- Industrial process water where seawater feed requires high rejection

Advantage One

Advantage 1 — High rejection for stable product water

Deliver consistently low product conductivity with robust polyamide selectivity and flow-balanced feed spacers that help control differential pressure across stages.Advantage TWO

Advantage 2 — Drop-in 8040 compatibility and serviceability

Standard 1.125″ permeate tube and multi-element vessel coupling enable fast change-outs in existing housings. Supported by clear acceptance criteria after start-up: normalized permeate flow ≥ 90–100% of the clean baseline, rejection at spec, and stage ΔP within limits.Related Products

Related products

- Water Treatment Accessories

Stark LP-4040 Industrial RO Membrane Element (High Flux 5L/min, 99.2% Rejection)

Read more

FAQ

Q1: How long does the reverse osmosis system last?

The lifespan of a reverse osmosis system depends on water quality and maintenance. Typically, the membrane lasts 2–3 years, while the system itself can last over 10 years with proper care.

Q2: Can the system be customized based on different water conditions?

Yes, all our systems are fully customizable. We analyze your water report and application needs before providing tailored solutions.

Q3: What standards does STARK equipment comply with?

Our products comply with CE, ISO 9001, and can be designed to meet specific regional regulations or industry standards upon request.

Q4: What is the delivery time for STARK RO systems?

Standard systems are shipped within 7–15 days. For customized orders, lead time may extend to 20–25 days depending on complexity.

Q5: Do you provide technical support or installation guidance?

Yes. We provide full technical documentation, remote guidance via video, and can dispatch engineers internationally upon request.

Q6: What is included in your quotation?

Our quotation includes the full RO system, control panel, pumps, pre-treatment units, and all necessary fittings. Installation tools and spare parts can be included upon request.