TL;DR. If you’re facing BOD TN TP non-compliance, start with a 4–8 week diagnostic, then move through a three-layer playbook: (1) quick control changes (DO/ABAC, internal recycle, SRT, alkalinity, dosing pacing); (2) tertiary polishing and EBPR stabilization to secure phosphorus; (3) structural upgrades (selectors, IFAS/MBBR, MBR, ozone/BAC, UV-AOP). Bring all decisions into a closed loop using online NH4/NO3/PO4/DO/ORP/UV254 data, a compliance dashboard, and defined alarm thresholds.

Back to: Municipal & Public Infrastructure Water Treatment Solutions

What “Non-Compliance” Means in 2025

This section frames how BOD TN TP non-compliance is defined and measured in permits so we fix the real problem, not a data artifact.

- Limits & statistics: permits increasingly use seasonal limits and statistics (e.g., monthly avg, weekly avg, daily max, P95). Always check how excursions are counted.

- Typical targets: BOD/TSS conventional secondary; TN ≤10 mg/L (many regions tighter); TP ≤0.5 mg/L (lower in sensitive waters); NH4 winter caps; turbidity when coupled with reuse/tertiary.

- Verification: recheck sampling points, chain-of-custody, lab QA/QC, and instrument calibration to ensure the problem is process, not data.

A Practical Diagnostic Matrix for BOD TN TP non-compliance

Use this field matrix before buying steel and concrete.

| Sintoma | Likely Root Cause | Rapid Check | Quick Fix (≤7 days) | Structural Fix (design level) |

|---|---|---|---|---|

| Effluent NH4 high | Insufficient nitrification (low SRT, cold temps, diffuser/blower limits, low alkalinity) | SRT calc; DO profile; alkalinity; diffuser headloss | Raise SRT (cut WAS), DO 1.5–2.0 mg/L; add alkalinity; enable ABAC | New diffusers/blowers; IFAS media; MBR |

| NO3/TN high | Poor denitrification (no true anoxic, low carbon, internal recycle too low/high) | Anoxic DO <0.2 mg/L? ORP? NO3 load | Lower anoxic DO; set internal recycle 2–4×; pace carbon to NO3 | Selectors, step-feed, intermittent aeration |

| TP swings / rebounds | EBPR instability; nitrate bleed; VFA shortage | Anaerobic PO4 release; VFA; nitrates in selector | Isolate true anaerobic; VFA via primary fermentation; chem-P trim | Tertiary filtration; improved selectors |

| TSS/BOD peaks | Clarifier bottleneck; sludge bulking; hydraulics | SVI; surface overflow; sludge blanket stability | RAS/WAS tuning; floc aid; weir cleaning | Weir/distribution retrofit; tertiary filters; MBR |

| Performance collapses in storms | Short-circuiting; no EQ; bypass | Flow/level curves vs basin HRT | Temporary bypass & EQ; adaptive DO setpoints | EQ basins; hydraulic rebalancing; peak-flow strategy |

| Dosing & air overuse | Open-loop control; sensor drift | Calibration history; variance vs load | Online analyzers; feedback loops (ABAC/NO3-paced carbon/PO4 feedback) | Standardized skids; SCADA upgrades |

| Sudden loss of biology | Toxic or inhibitory industrial discharge | Toxicity screen; ORP anomalies; unusual odors | Bypass/dilution; alkalinity; PAC/GAC dosing | Industrial pretreatment program; online toxicity |

Root Cause #1 — Insufficient Nitrification

The most common driver of BOD TN TP non-compliance in winter is insufficient nitrification.

What it looks like

NH4 spikes in winter; rising effluent NO2; TN above target despite adequate carbon.

Quick fixes

- Raise SRT (cut WAS) to ≥8–12 d in cold conditions.

- Maintain aerobic DO 1.5–2.0 mg/L and verify diffuser performance.

- Restore alcalinidade (nitrification consumes ~7.1 mg CaCO3/mg NH4-N).

- Implement ABAC (ammonia-based aeration control) to trim air while protecting effluent NH4.

Design paths

Upgrade diffusers/blowers; introduce IFAS/MBBR media to retain nitrifiers; consider MBR where clarifiers are at capacity or reuse is planned. Explore aeration & MBR modules e DO/NH4 analyzers.

Root Cause #2 — Denitrification Failure

Sintomas

Effluent NO3 stuck high; carbon use heavy; ORP hovers too positive in “anoxic” zones.

Quick fixes

- Create true anoxic conditions (DO <0.2 mg/L); fix air leaks.

- Set internal recycle at 2–4× influent; avoid short-circuiting.

- Pace external carbon to NO3-N load using online NO3/ORP; cap max dose and smooth ramps.

Design paths

Add selectors and step-feed; use intermittent aeration; modernize control logic.

Root Cause #3 — EBPR Instability & Phosphorus Rebound

Sintomas

Unstable EBPR is a frequent cause of phosphorus-related BOD TN TP non-compliance, especially at low temperature.

TP swings, particularly at low temperature or variable loads; inconsistent anaerobic PO4 release.

Quick fixes

- Ensure a true anaerobic selector (no nitrate bleed from RAS/IR).

- Increase VFA via primary fermentation or sidestreams.

- Utilização chem-P trimming (alum/ferric) with online orthophosphate feedback.

Design paths

Pair EBPR with tertiary filtration (cloth/disk/sand) to stabilize ≤0.5 mg/L TP; refine selectors and recycles.

Root Cause #4 — Solids Separation & Clarifier Bottlenecks

Sintomas

TSS/BOD peaks, SVI high, sludge blanket unstable, wet-weather washout.

Quick fixes

- Tune RAS/WAS; adjust sludge age; maintain weirs and scum removal.

- Temporary polymer aid during storms or maintenance windows.

Design paths

Retrofit distribution and weirs; add tertiary filters; shift to MBR if clarifiers cap capacity or reuse is priority.

Root Cause #5 — Hydraulics & Wet-Weather Short-Circuiting

Quick fixes

- Deploy temporary equalization; implement adaptive DO setpoints and step-feed during storms.

- Protect solids with conservative surface loading rates and weir uniformity.

Design paths

Construct EQ basins; re-balance hydraulics; define peak-flow bypass strategy with compliant sampling.

Root Cause #6 — Monitoring & Control Gaps

Problem statement

Open-loop dosing and drifting sensors often sit behind recurring BOD TN TP non-compliance.

Open-loop air and chemicals waste cost and cause variability. Sensor drift erodes trust.

Closed-loop solution

- Standardize online NH4/NO3/PO4/DO/ORP/UV254 with calibration SOPs.

- Close loops: ABAC for air; NO3-paced carbon; PO4 feedback for chem-P; UV254 feed-forward for coagulants.

- Connect to PLC/SCADA and historian; institute alarm thresholds and drills.

See sensors, analyzers & dosing skids for standardized packages.

Root Cause #7 — Industrial Loads & Toxicity Shocks

Quick fixes

- Bypass/dilution; add alkalinity; PAC/GAC for short-term adsorption.

Longer-term

Implement industrial pretreatment requirements; add online toxicity monitoring; collaborate on source substitution.

Quick Wins You Can Do in 30 Days

- Aeration: replace aged diffusers; verify α/β and SOTE; stage DO; enable ABAC.

- Dosing: convert flow-paced to load-paced with online signals; cap rates, add ramp limits.

- Operations: publish SRT/WAS calendar; clean clarifier weirs; track SVI weekly.

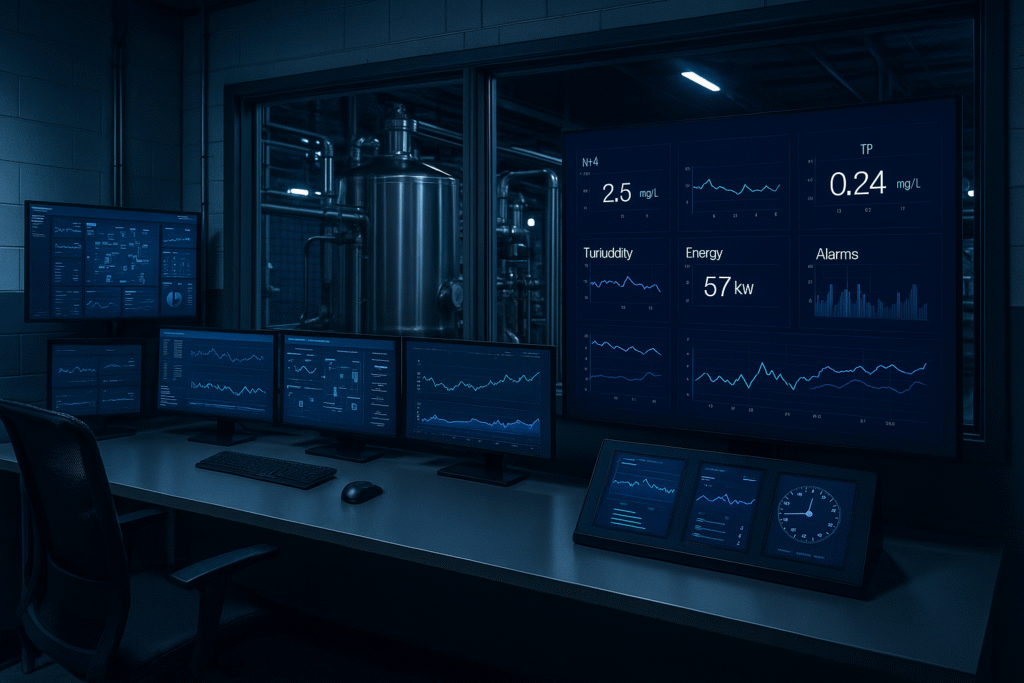

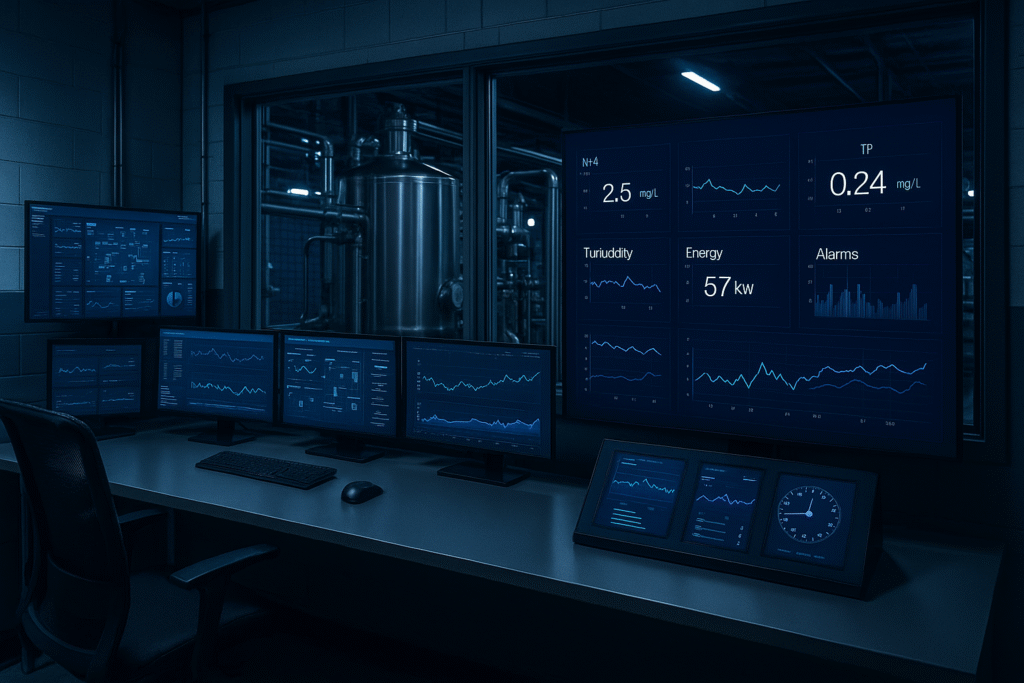

- Data: launch a compliance dashboard with red/amber/green thresholds and daily stand-ups.

These quick wins typically resolve day-to-day BOD TN TP non-compliance while design upgrades are prepared.

Design-Level Fixes

When controls aren’t enough, the following upgrades permanently eliminate BOD TN TP non-compliance.

- Selectors, IFAS/MBBR, or MBR for biology & solids control.

- Tertiary filtration for TSS/TP polishing.

- Ozone + BAC, UV-AOP for micropollutants; add RO/NF if reuse class requires.

- Energy upgrades: high-efficiency blowers, VFDs, optimized control maps.

Navegar plant modules e accessories for specification-ready packages.

Closed-Loop Online Monitoring Architecture

Sensors & setpoints (example)

| Point | Measurement | Use in Control | Maintenance |

|---|---|---|---|

| Aerobic zones | DO, NH4 | ABAC & DO staging | Calibrate weekly; replace membranes as per OEM |

| Anoxic zones | NO3, ORP | NO3-paced carbon; verify true anoxic | Clean optics; 2-pt check monthly |

| EBPR selector | PO4, NO3 | Prevent nitrate bleed; EBPR health | Weekly check |

| Tertiary influent | PO4, turbidity | Chem-P feedback; filter protection | Weekly check |

| Advanced treatment | UV254/TOC | Ozone/AOP dose control | Clean windows; verify baselines |

Control loops

- ABAC: Target effluent NH4 with DO caps; trim air without risking spikes.

- NO3-paced carbon: External carbon follows NO3-N load with anti-windup and daily caps.

- PO4 feedback: Dose to effluent orthophosphate targets while watching alkalinity and sludge yield.

- UV254 feed-forward: Coagulant dose reacts to organics/turbidity swing before filters.

Data governance & OT security

- Zone OT networks; role-based access; change logs; backup/restore drills.

- Historian with immutable retention for audits; KPI rollups and anomaly detection.

Compliance Dashboard & KPIs

A live dashboard turns BOD TN TP non-compliance into an early-warning signal with actionable thresholds.

| KPI | Why it matters | Typical Target |

|---|---|---|

| NH4, NO3, TN | Nitrogen compliance & air/carbon control | Meet permit; keep guard bands in winter |

| TP | EBPR/chem-P performance | ≤0.5 mg/L; lower with tertiary |

| TSS/Turbidity | Solids capture; filter/AOP readiness | <2–5 NTU typical |

| kWh per m³ | Energy intensity | ≤0.30–0.35 (site-specific) |

| Chemicals per m³ | Cost & carbon footprint | Downward trend with control |

| Alarm response time | Operational discipline | <5 minutes for critical |

Case Snapshots (Anonymized)

Case A — Winter NH4 Spikes

Action: Raise SRT; replace diffusers; enable ABAC. Result: NH4 excursions eliminated; energy −19%.

Case B — EBPR Rebound

Action: True anaerobic selector; VFA via primary fermentation; chem-P trim; tertiary cloth filter. Result: TP 0.25–0.35 mg/L steady.

Case C — Wet-Weather Washout

Action: Temporary EQ; step-feed; clarifier weir retrofit. Result: TSS/BOD peaks disappeared in storms.

Implementation Checklist

Weekly

- Instrument calibration (DO/NH4/NO3/PO4/ORP) and grab sample verification.

- SVI, MLSS, SRT calc; WAS calendar adhered.

- Clarifier inspections; weir/scum cleanup.

Monthly

- Energy audit (blower share, kWh per m³); chemical intensity per m³.

- Dashboard review; top 5 alarms; corrective actions logged.

Quarterly/Annual

- HAZOP refresh; emergency drills (ozone/UV safety, chemical handling).

- Process capability & compliance statistics; revamp setpoints.

FAQs

Q1. What are the first three steps to cut TN quickly?

Raise SRT, stabilize DO with ABAC, create true anoxic zones and pace carbon to NO3-N load.

Q2. EBPR unstable—what to check first?

Nitrate bleed into the anaerobic selector, VFA availability, and SRT/temperature alignment for PAOs.

Q3. How to avoid over-dosing external carbon?

Use NO3-paced control with anti-windup and daily caps; audit effluent NO3 and ORP.

Q4. PO4 online readings fluctuate—what’s the fix?

Check sample lines for bubbles; clean optics; perform two-point calibration; confirm with lab.

Q5. How do we keep TSS/BOD compliant during storms?

Equalize flows, step-feed, maintain conservative clarifier loadings, deploy polymer aid, and protect weirs.

Recommended Products & Internal Links

- Accessories & Dosing (sensors, metering pumps, analyzers, ORP/UV254)

- Plant Modules (MBR, aeration systems, tertiary filters)

- Municipal Solutions Pillar

- Pedir um orçamento

Author: STARK Process Engineering Team | Technical review: Senior Municipal Water Specialist | Last reviewed: 2025-08-15

References (add external links on publish): WHO Guidelines for Drinking-water Quality; US EPA nutrient removal & advanced wastewater resources; EU Urban Waste Water Treatment Directive; IWA/WEF technical reports on EBPR, aeration, ozone/BAC, and reuse.