Purificador de água RO 6000LPH, Equipamento de tratamento de água RO com controlo PLC

Purificador de água RO 6000LPH, Equipamento de tratamento de água RO com controlo PLCPurificador de água RO 6000LPH, Equipamento de tratamento de água RO com controlo PLC

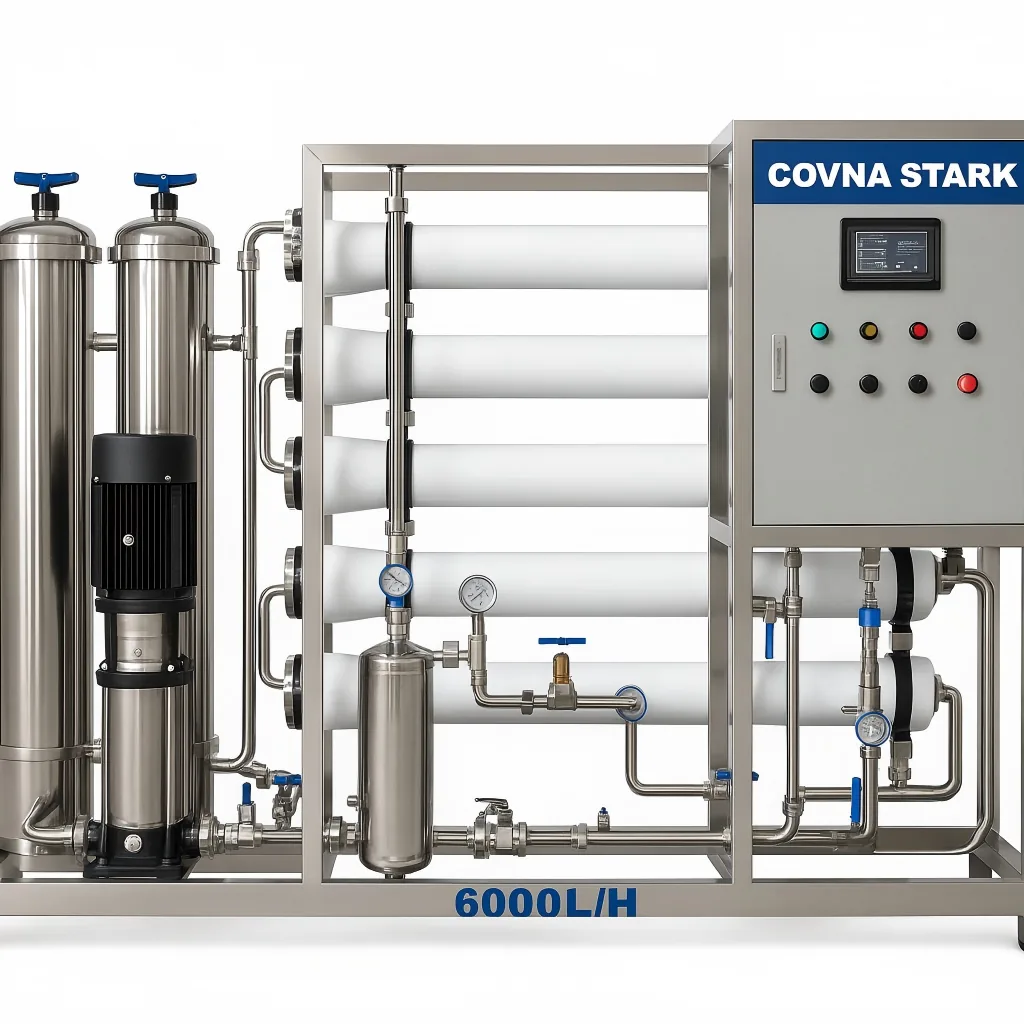

6000 LPH RO Water Purification System by STARK delivers stable, low-TDS process water for factories, bottling, and commercial buildings. Skid-mounted design with PLC/HMI, auto-flush, and safety interlocks. Recovery engineered to your feedwater. Request a tailored quote.

Descrição do produto

O 6000 LPH RO Water Purification System is engineered for continuous industrial service. Using reverse osmosis membranes, it removes dissolved salts, organics, and particles to produce consistent permeate for boiler make-up, ingredient water, and rinsing lines. A typical train combines multimedia and activated-carbon filtration, a 5 μm cartridge, a stainless-steel high-pressure pump, and automatic flush cycles to reduce fouling. PLC/HMI control with low-/high-pressure interlocks improves reliability and simplifies daily operation. Standard recovery is 60–65% and can be tuned to your feed TDS, SDI, and scaling index. Options include a VFD high-pressure pump, 2-pass RO or RO+EDI for ultra-low conductivity, UV/ozone post-treatment, a CIP package, and remineralization. The compact, skid-mounted layout reduces footprint and service time—helping you deploy a scalable, energy-aware industrial RO system across plants.

Designed for reliable, 24/7 operation, the STARK 6000 LPH RO system converts municipal or well water into consistently pure process water. A typical process train includes media filtration / activated carbon, cartridge filtration, high-pressure ROe automatic flush sequences to reduce fouling. The compact skid minimizes footprint while providing front-access to pumps, instrumentation, and membranes for fast service.

Why it works: Reverse osmosis uses a semi-permeable membrane to reject dissolved salts, organics, microorganisms, and particulates—delivering permeate that meets downstream needs (boiler makeup, ingredient water, rinsing, etc.). For most industrial sources, 60–65% recovery is a balanced starting point; higher or lower recovery can be engineered based on feed TDS, temperature, SDI, and scaling indices. (STARK provides on-request feedwater testing and sizing.)

Integration & scalability: The system supports options like VFD high-pressure pump, UV/ozone post-treatment, alkalinity re-mineralization, CIP package, or 2-pass RO / EDI when ultra-low conductivity is required. For multi-site rollouts, STARK offers global technical support and spares logistics through our RO product line.

Parâmetro do produto

| Rated Permeate | 6,000 L/h (configurable) |

|---|---|

| Recovery (single-pass) | 60–65% typical; engineered per feed TDS/SDI/LSI |

| Salt Rejection | 96–99% (membrane-dependent) |

| Pré-tratamento | Multimedia → Activated Carbon → 5 μm cartridge |

| Membranas RO | 4″ or 8″ elements (brand per BOM) |

| Bomba de alta pressão | Stainless-steel multistage, VFD optional |

| Control | PLC/HMI, auto-flush, low/high-pressure interlocks |

| Electrical | 380–415 V/50 Hz or 460 V/60 Hz (site standard) |

| Frame & Piping | Stainless-steel skid, SS/UPVC process lines |

Note: Final values are confirmed after feedwater analysis; STARK provides sizing and testing on request.

Setor aplicável

-

-

Food & Beverage — ingredient water, CIP make-up

-

Bottled Water / Beverage — product & rinse water

-

Pharma / Cosmetics / Lab — pre-polish for DI/EDI

-

Electronics & Metal Finishing — low-conductivity rinsing

-

Commercial & Institutional — hospitals, hotels, campuses

-

Boiler & Cooling Make-Up — scale/corrosion-controlled supply

-

Vantagem Um

Advantage 1 — High-Efficiency, Service-Friendly

-

Compact skid with clear service access

-

Auto-flush & safety interlocks reduce fouling risk

-

VFD-ready high-pressure pump for energy optimization

-

Modular options: CIP, 2-pass, RO+EDI, UV/ozone, remineralization

Vantagem DOIS

Advantage 2 — Consistent Quality & Expert Support

-

Stable permeate for critical processes

-

Engineered recovery to balance water cost vs. fouling

-

Global spares & remote guidance from STARK

-

Proven architecture for scalable deployments

Produtos relacionados

Produtos Relacionados

FAQ

Q1: Quanto tempo dura o sistema de osmose inversa?

A vida útil de um sistema de osmose inversa depende da qualidade da água e da manutenção. Normalmente, a membrana dura 2-3 anos, enquanto o sistema em si pode durar mais de 10 anos com os cuidados adequados.

Q2: O sistema pode ser personalizado com base nas diferentes condições da água?

Sim, todos os nossos sistemas são totalmente personalizáveis. Analisamos o seu relatório de água e as necessidades da aplicação antes de fornecer soluções à medida.

Q3: A que normas obedece o equipamento STARK?

Os nossos produtos estão em conformidade com a norma CE, ISO 9001, e podem ser concebidos para cumprir regulamentos regionais específicos ou normas industriais, mediante pedido.

Q4: Qual é o prazo de entrega dos sistemas STARK RO?

Os sistemas standard são enviados no prazo de 7 a 15 dias. Para encomendas personalizadas, o prazo de entrega pode prolongar-se até 20-25 dias, dependendo da complexidade.

Q5: Prestam assistência técnica ou orientação para a instalação?

Sim. Fornecemos documentação técnica completa, orientação remota através de vídeo e podemos enviar engenheiros internacionalmente mediante pedido.

Q6: O que está incluído no vosso orçamento?

O nosso orçamento inclui o sistema RO completo, o painel de controlo, as bombas, as unidades de pré-tratamento e todos os acessórios necessários. As ferramentas de instalação e as peças sobresselentes podem ser incluídas mediante pedido.