Caixa da membrana em aço inoxidável STARK 4040

Caixa da membrana em aço inoxidável STARK 4040Caixa da membrana em aço inoxidável STARK 4040

Ensure reliable performance and robust protection for your RO membranes with Stark Water’s 4040 Stainless Steel Membrane Housing. This durable stainless steel membrane housing is designed for 4040 RO elements, providing secure, leak-proof containment crucial for various industrial and commercial reverse osmosis systems.

Descrição do produto

In any efficient Reverse Osmosis (RO) system, the membrane housing serves as a critical component, providing the robust and secure environment necessary for RO membranes to function under high pressure. The STARK 4040 Stainless Steel Membrane Housing is meticulously engineered to deliver exceptional durability, reliability, and protection for your RO elements in demanding industrial and commercial applications. This housing stands as a testament to superior engineering, ensuring the longevity and optimal performance of your water purification infrastructure.

Built for 4040 RO Membranes

This **stainless steel membrane housing** is precisely designed to accommodate standard **4040 RO membrane** elements (4-inch diameter, 40-inch length). This common size makes our housing highly compatible with a wide range of industrial and commercial RO systems, offering versatile integration options. The internal dimensions are optimized to ensure a perfect fit for the membrane, preventing bypass of untreated water and maximizing the efficiency of the reverse osmosis process, thus ensuring consistently high-quality permeate production.

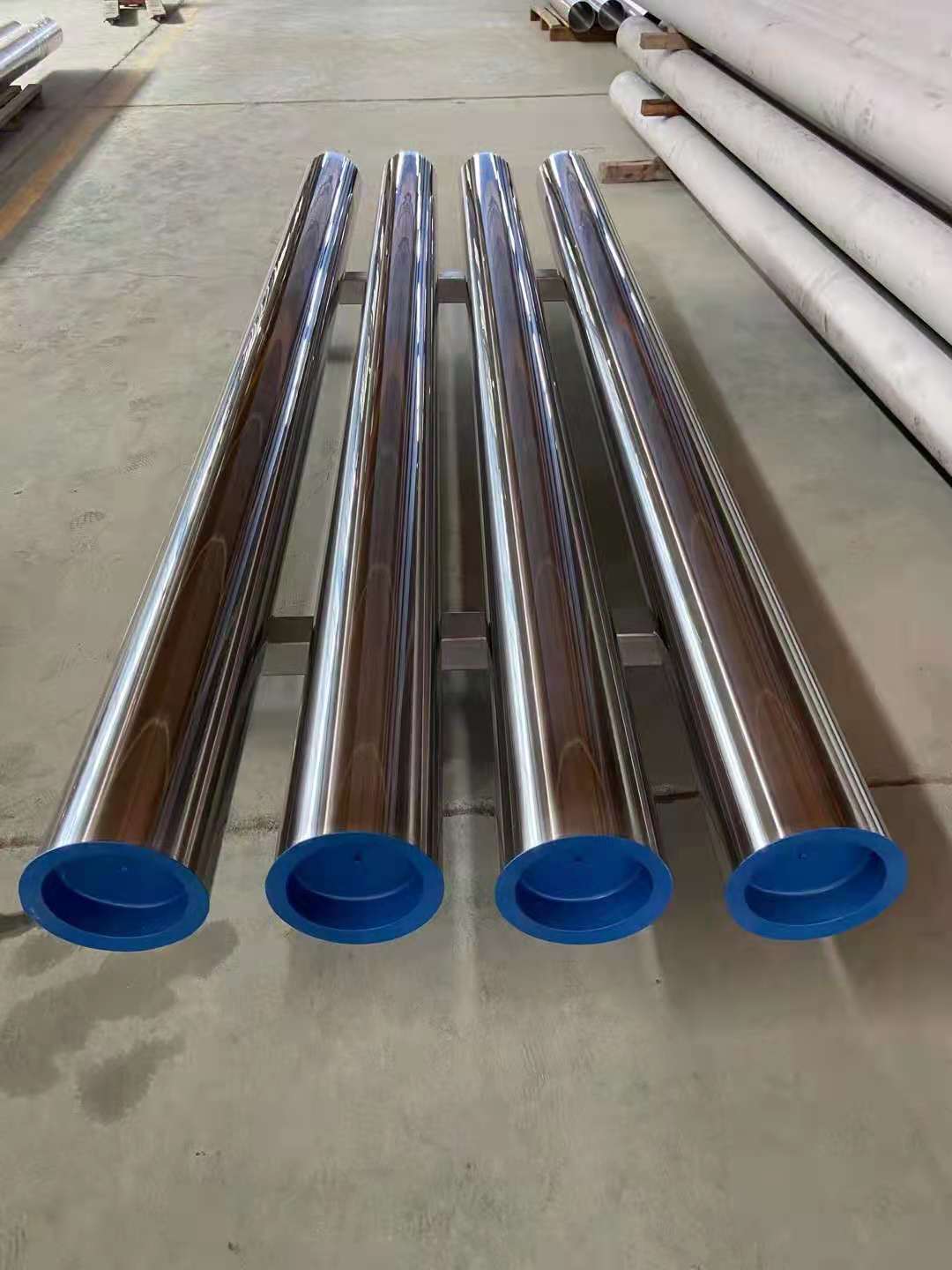

Premium Stainless Steel Construction & High-Pressure Resilience

Durability, corrosion resistance, and safety are paramount for any pressure-bearing component in water treatment. Our 4040 membrane housing is constructed exclusively from high-grade **stainless steel** (typically SUS304 or SUS316L, depending on the application’s specific requirements for corrosion resistance). This material choice provides exceptional resilience against aggressive water chemistries, corrosive environments, and high operating pressures common in RO systems. The robust construction allows the housing to safely contain the significant internal pressures (often ranging from 200-600 PSI or more for brackish and seawater applications) required for efficient RO operation, ensuring a secure and reliable containment vessel for your valuable membranes.

Absolutely Sealed Design for Uncompromised Purity

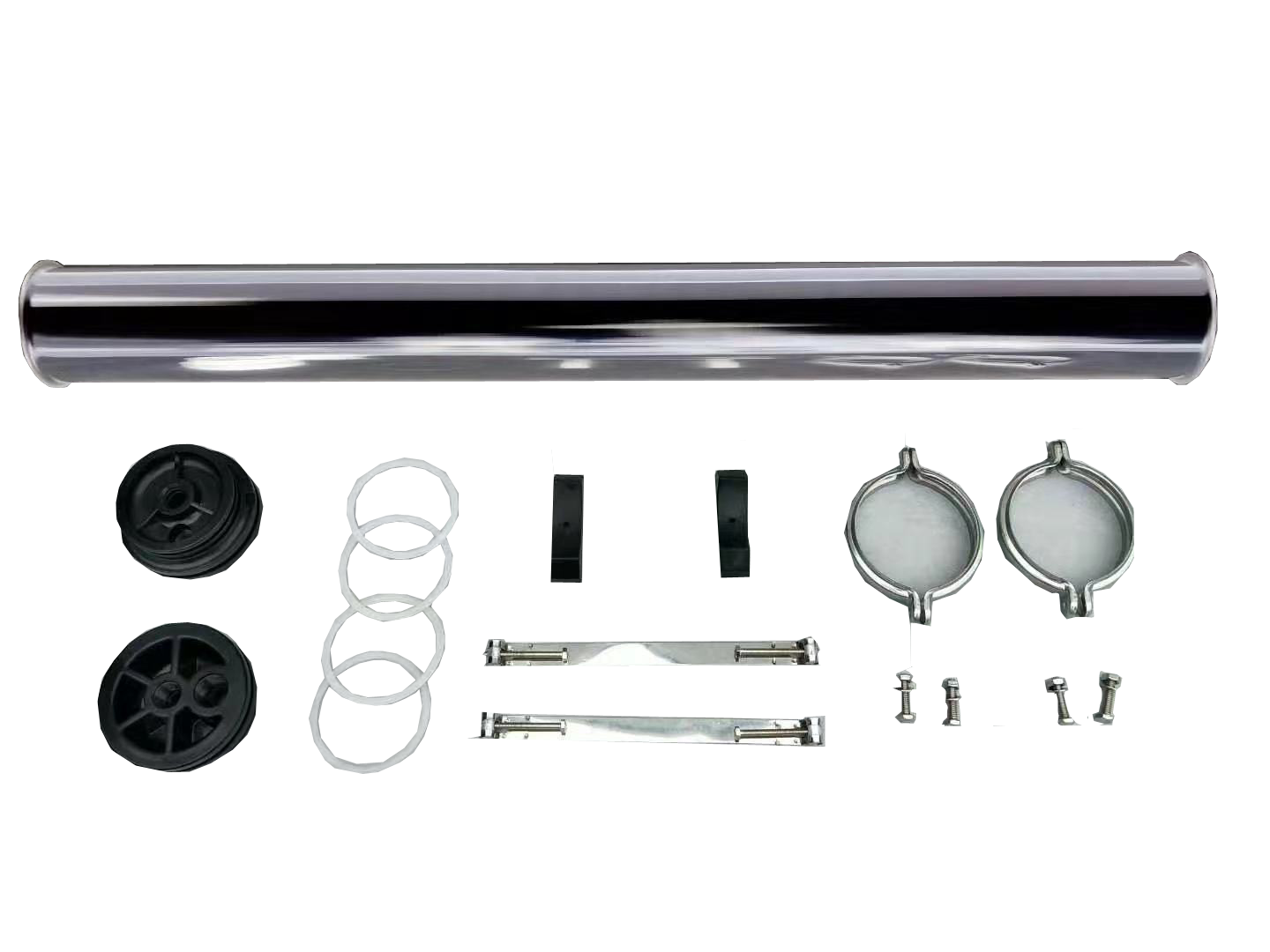

A hallmark of the STARK 4040 membrane housing is its **absolutely sealed design**. Precision machining and the use of high-quality, long-lasting O-rings ensure a leak-proof seal under all operating conditions. This critical design feature prevents any untreated feedwater from bypassing the RO membranes and contaminating the purified water stream. By guaranteeing that all liquid passes through the filtration process, our membrane housing contributes directly to consistently high-quality permeate, safeguarding your final product and the integrity of your downstream processes.

Ease of Installation, Maintenance, and Long-Term Value

Designed with practicality in mind, our stainless steel membrane housing facilitates straightforward installation and relatively easy maintenance. Its robust build and high-quality materials significantly reduce the need for frequent replacements or repairs, contributing to lower long-term operational costs. By providing superior protection for your sensitive RO membranes from external damage and ensuring efficient flow dynamics, our **stainless steel membrane housing** effectively extends the lifespan of your entire RO system. This translates into reliable, uninterrupted water purification and excellent value over the system’s operational life.

Parâmetro do produto

| Parâmetro | Especificação / Opções de personalização |

|---|---|

| Foco na palavra-chave principal | Stainless Steel Membrane Housing conceção e capacidades. |

| Compatible Membrane Size | 4040 (4-inch diameter, 40-inch length) RO Membrane Elements. Can accommodate 1 to 3+ elements per vessel (depending on model). |

| Material de construção | Stainless Steel (SUS304 or SUS316L, specific grade can be chosen based on application and water chemistry). |

| Tipo de desenho | End-entry or Side-entry ports. Individual or multi-element configurations. |

| Máx. Pressão de funcionamento | Typically 300 PSI, 450 PSI, 600 PSI (designed to specific pressure requirements for brackish or clean water RO). |

| Máx. Temperatura de funcionamento | Up to 49°C (120°F) – depending on sealing materials. |

| Permeate Port Size | Standard ¾” or 1″ NPT/BSP. |

| Concentrate/Inlet Port Size | Standard 1″ or 1.5″ NPT/BSP. |

| End Cap Material | Stainless Steel (compatible with housing material) or durable ABS/PVC. |

| Sealing Material | EPDM, Viton (FKM), Buna-N (NBR) O-rings (selected based on chemical compatibility and temperature). |

| Acabamento da superfície | Polished or Pickled/Passivated (internal and external) for enhanced corrosion resistance. |

| Mounting Saddles | Included stainless steel saddles for secure mounting. |

| Testing & Certification | Pressure tested; ASME code stamp available upon request for specific pressure vessel requirements. |

Setor aplicável

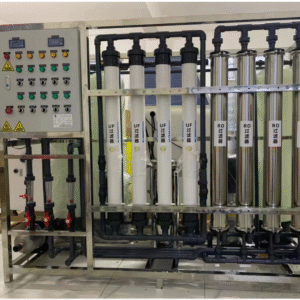

- Industrial Water Treatment Plants: Serving as the core containment for 4040 RO membranes in various systems providing purified water for manufacturing processes, utility, and general industrial use.

- Indústria de alimentos e bebidas: Used in RO systems that produce high-purity process water for bottled water production, beverage formulation, dairy processing, and food ingredient preparation, ensuring product consistency and safety.

- Pharmaceutical & Medical Industry: Critical for RO systems generating Purified Water (PW), pre-treatment for Water for Injection (WFI), and other high-purity water requirements for drug manufacturing and medical device reprocessing, adhering to strict GMP standards.

- Laboratories & Research Facilities: Essential for housing RO membranes that supply high-purity water for analytical testing, reagent preparation, and sensitive experimental procedures.

- Commercial & Institutional Water Supply: For RO systems providing purified drinking water for hotels, resorts, schools, hospitals (non-critical areas), and large commercial buildings.

- Power Generation: Utilized in RO systems for boiler feed water pre-treatment and cooling tower make-up water, preventing scaling and corrosion in expensive equipment and improving energy efficiency.

- Brackish Water Treatment: For purifying groundwater with high mineral content for various commercial, agricultural, and municipal applications.

- Tratamento e reutilização de águas residuais: Employed in RO stages of advanced wastewater treatment facilities to produce high-quality effluent for discharge or reuse, especially in smaller scale industrial processes.

- Automotive & Metal Finishing: Used in RO systems to provide high-purity rinse water for electroplating, painting, and metal treatment processes, improving finish quality and reducing defects.

Vantagem Um

Vantagem DOIS

Produtos relacionados

Produtos Relacionados

-

Equipamento de ultrafiltração

Reverse Osmosis ystem Water UF Equipment Manufacturer

Adicionar ao orçamento

FAQ

Q1: Quanto tempo dura o sistema de osmose inversa?

A vida útil de um sistema de osmose inversa depende da qualidade da água e da manutenção. Normalmente, a membrana dura 2-3 anos, enquanto o sistema em si pode durar mais de 10 anos com os cuidados adequados.

Q2: O sistema pode ser personalizado com base nas diferentes condições da água?

Sim, todos os nossos sistemas são totalmente personalizáveis. Analisamos o seu relatório de água e as necessidades da aplicação antes de fornecer soluções à medida.

Q3: A que normas obedece o equipamento STARK?

Os nossos produtos estão em conformidade com a norma CE, ISO 9001, e podem ser concebidos para cumprir regulamentos regionais específicos ou normas industriais, mediante pedido.

Q4: Qual é o prazo de entrega dos sistemas STARK RO?

Os sistemas standard são enviados no prazo de 7 a 15 dias. Para encomendas personalizadas, o prazo de entrega pode prolongar-se até 20-25 dias, dependendo da complexidade.

Q5: Prestam assistência técnica ou orientação para a instalação?

Sim. Fornecemos documentação técnica completa, orientação remota através de vídeo e podemos enviar engenheiros internacionalmente mediante pedido.

Q6: O que está incluído no vosso orçamento?

O nosso orçamento inclui o sistema RO completo, o painel de controlo, as bombas, as unidades de pré-tratamento e todos os acessórios necessários. As ferramentas de instalação e as peças sobresselentes podem ser incluídas mediante pedido.