This reverse osmosis winterization guide shows exactly how to protect an RO plant through freezing weather—whether you keep it running, idle it overnight, or mothball it for the season. You’ll get a 12-step checklist, drainage map, membrane preservation options, and safe-restart verification to minimize damage, downtime, and salt-passage excursions.

At-a-glance (why it matters):

- Ice expands ~9% and can crack RO housings, valves and gauges in hours.

- Most failures occur at low points, small lines (sample ports/PRV capillaries) and outdoor runs.

- Reverse osmosis winterization = temperature control + drainage + membrane preservation + safe restart checks.

1) Choose your winter mode

Operating

- Keep room temp ≥5 °C; seal doors, fix drafts.

- Verify heat-trace/insulation on raw feed, concentrate, drains, vent lines; log amps.

- Night strategy: low-flow recirculation to avoid cold stagnation.

Idle (overnight/weekend)

- Warm room, keep low-flow bypass or drain exposed low points.

- Disable auto-starts; lockout if freezing risk overnight.

Seasonal storage

- Full drain & blow-down; membrane wet- or dry-storage; chemical day-tanks empty.

2) Reverse osmosis winterization decision matrix

| Ambient condition | Operating | Idle ≤48h | Seasonal storage |

|---|---|---|---|

| ≥ 5 °C (41 °F) | Run normally; verify room temp logs; insulate cold drafts. | Keep recirc 0.2–0.4 m/s or drain only exposed stubs. | Optional; prefer wet storage if room stays above freezing. |

| 0…5 °C (32–41 °F) | Run with heat-trace live; check low points daily. | Drain all low points; disable auto-start; lockout pumps. | Wet storage with ~1% SBS; room must remain >0 °C. |

| < 0 °C (<32 °F) | Strongly avoid idle stops; keep recirc; verify alarms. | Full drain & blow-down; crack vents; tag status. | Dry storage (air-purge & cap) or relocate to heated room. |

3) 12-step reverse osmosis winterization procedure

- Lockout/tagout MCCs and chemical dosing as required.

- Record baselines: feed/permeate/concentrate flows, ΔP by stage, salt passage vs. permeate temperature.

- Clean in place (if due) to reduce biofouling prior to storage.

- Flush to permeate: low-pressure flush so housings hold permeate, not concentrated brine.

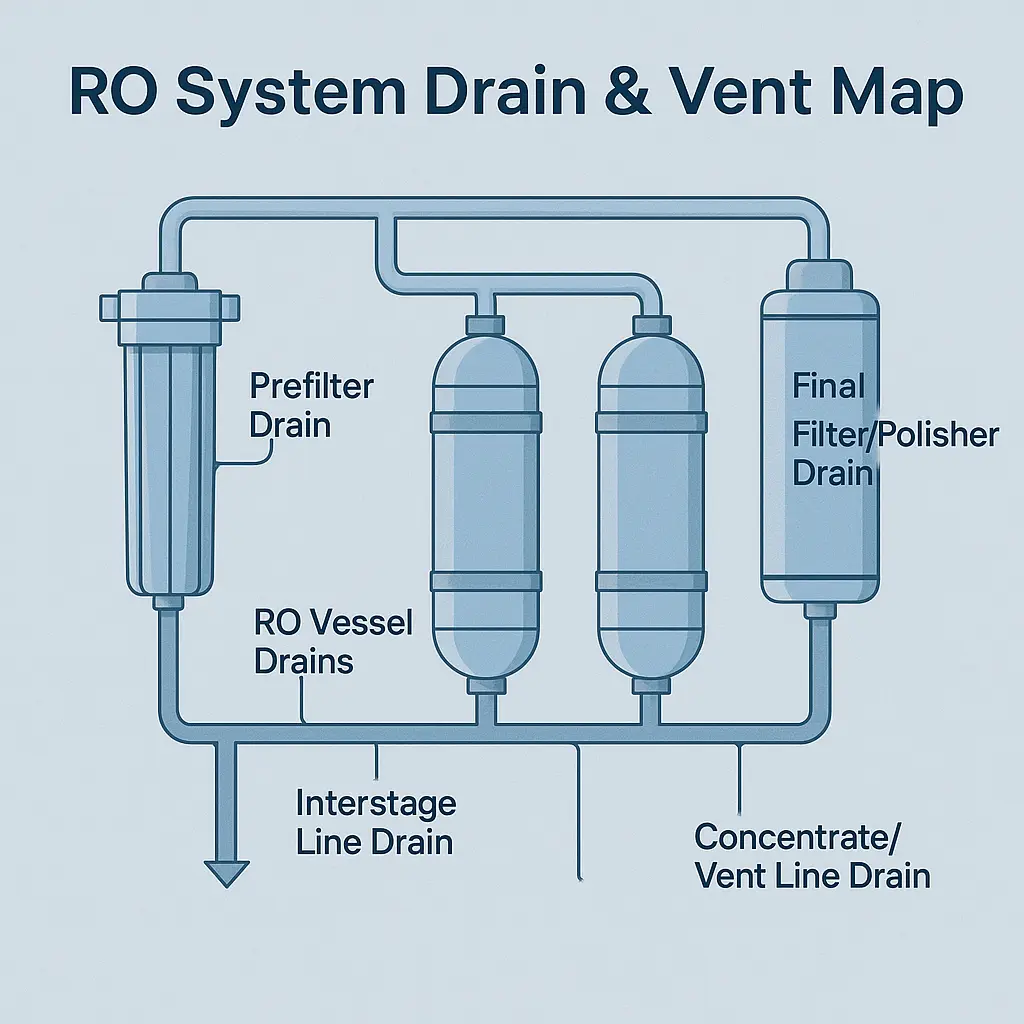

- Drain low points in this order: prefilters → RO housings → interstage lines → final filters → drains/vents.

- Air blow-down: regulate to <0.3 MPa; blow from high to low while drains are open.

- Open vents/manways on MMF, carbon, softeners; drain chemical day-tanks and tubing.

- Membrane preservation:

- Rooms >0 °C: wet-store with ~1% sodium bisulfite (SBS). Confirm free chlorine = 0 before dosing.

- Sub-freezing: dry storage—drain, air-purge, cap vessels, label and log serials.

- Pressure release on accumulators; remove gauge columns where freezing is likely.

- Heat-trace & insulation audit: verify breakers, GFCIs, amp draw, labels and coverage on drains and vents.

- Room controls: set thermostats ≥5 °C; add temp data loggers with alarms.

- Documentation: update P&IDs; tag every drained/isolated component; capture photos.

4) Thawing and safe restart

- Warm equipment to ≥10 °C; no open flames or steam shocks.

- Inspect housings, O-rings, gauges, sight-glasses, valves for cracks or leaks; replace as needed.

- Refill, purge air, and ramp slowly while watching ΔP by stage.

- Verify performance: compare flows, ΔP and salt passage vs. baseline; only then go to design recovery.

5) Drain & verification checklists

| Component | Drain/vent point | Tag | Status |

|---|---|---|---|

| 5 µm prefilter (cartridge) | Bottom bowl drain | PF-D1 | □ Opened □ Closed |

| RO vessel train | Each end cap & center drain | RO-D* | □ Purged with air □ Capped |

| Interstage line | Lowest tee drain | IS-D1 | □ Drained |

| Final filter/polisher | Housing drain + vent | FF-D1 | □ Drained |

| Concentrate/vent lines | Line-end drip leg | CL-D1 | □ Drained |

| Metric | Baseline | Post-restart | Pass/Fail |

|---|---|---|---|

| Permeate flow (m³/h) | __ | __ | □ |

| Stage-1 ΔP / Stage-2 ΔP (bar) | __/__ | __/__ | □ |

| Salt passage (%) @ temp-corrected | __ | __ | □ |

| Leaks/visual damage | — | __ | □ |

6) Daily & weekly winter ops

- Room temp logs (min/max) and heat-trace amperage check.

- Low-point drain inspection and vent icing check.

- Chemical levels (SBS/antiscalant) and alarm tests.

- Gasket/seal walk-down after first hard freeze and first thaw.

7) Bill of materials

- Heat-trace cable & controllers, fiberglass or elastomeric insulation, weatherproof jacketing.

- Non-contact IR thermometer; temp data loggers with alarms.

- Regulated compressed-air kit for blow-down; tags/labels.

- Sodium bisulfite (SBS) for wet storage; site-approved cleaners for CIP.

8) Common mistakes & fast fixes

- Inadequate dechlorination → membrane oxidation: raise SBS at static mixer, verify residence and zero free Cl₂ before preservation.

- Dead legs/reverse slopes → redesign tees, enforce 1–2% slope, add drains at drip legs.

- CO₂ depresses resistivity after restart → add degassing/conditioning interstage or hold for stabilization.

- TOC creep → sanitize (UV/185 or hot water where compatible) and refresh cadence.

9) Compliance & references

- ASTM D1193 classes for reagent water (design targets & verification).

- Water Quality Association (WQA) resources for system qualification and sanitation.

10) Next steps (RFQ & internal links)

Share your RO permeate analysis and demand curve—we’ll size heat-trace, drainage points, membrane storage method and a hygienic stainless-steel package.

Helpful internal references: RO troubleshooting · DI storage tank & loop design · EDI vs mixed bed · Stainless steel tanks & housings

© Stark Water • Engineering content for industrial readers. This page covers reverse osmosis winterization practices; always follow your OEM and site procedures.