Nanofiltration Membrane Maintenance: 4 Critical Mistakes to Avoid

Effective Nanofiltration Membrane Maintenance is the key to ensuring long-term stability in modern water treatment projects. In recent years, stricter environmental regulations have accelerated the adoption of Wastewater Reuse and Zero Liquid Discharge (ZLD). As traditional Ultrafiltration (UF) and Reverse Osmosis (RO) struggle with complex water qualities, Nanofiltration (NF) has emerged as a vital technology.

However, many operators misunderstand the specific requirements of nanofiltration membrane maintenance. While NF membranes are made of polyamide composites similar to RO, their operational needs differ significantly. At Stark Water, we often see system failures caused by improper care.

In this guide, we will clarify the technical definition of NF and outline four critical nanofiltration membrane maintenance protocols to extend the lifespan of your equipment.

Understanding Nanofiltration and Maintenance Needs

There is a common misconception that Nanofiltration is simply a “loose” version of Reverse Osmosis. This is technically inaccurate and can lead to poor Nanofiltration membrane maintenance strategies.

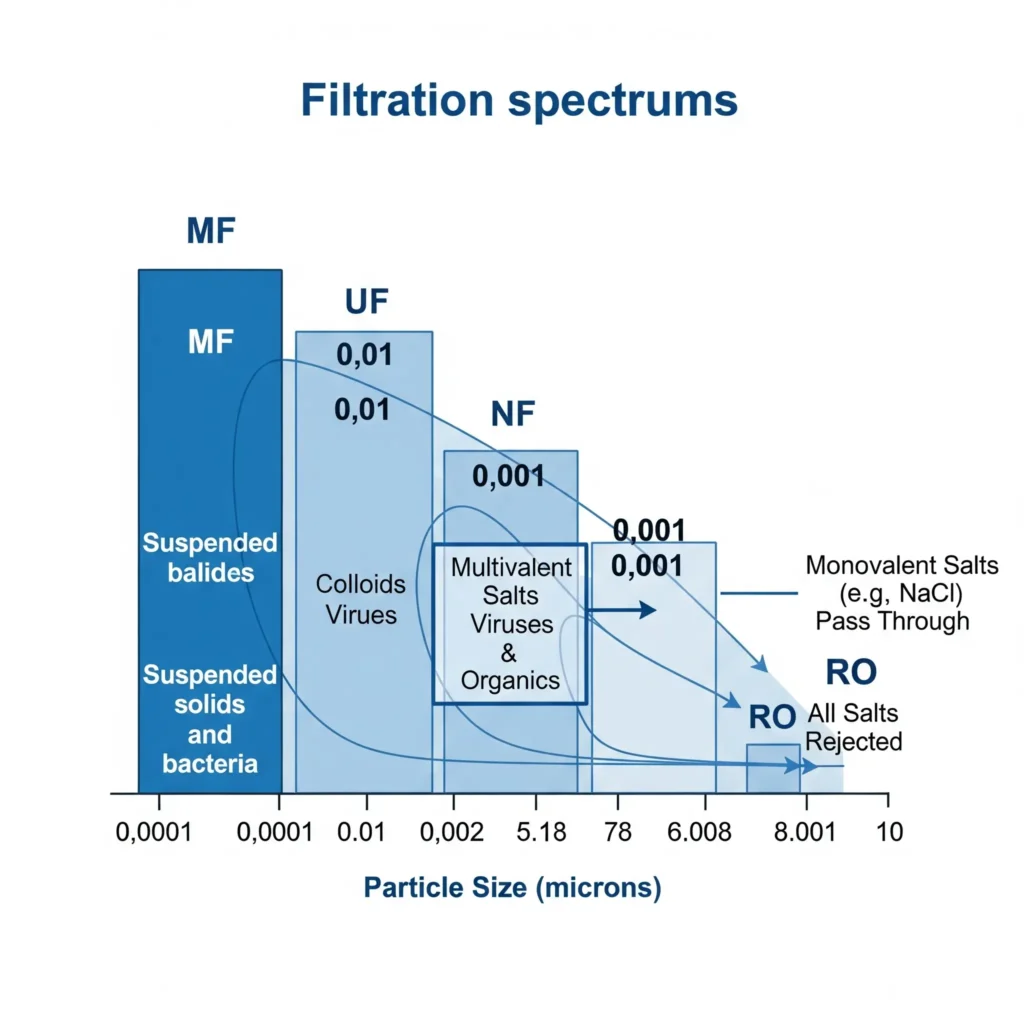

True Nanofiltration is a selective separation membrane based on the Donnan Effect. It is characterized by a molecular weight cutoff (MWCO) of 150–300 Daltons. Unlike RO, which rejects almost all ions, NF is designed to:

- Permeate Monovalent Salts: It allows salts like Sodium Chloride (NaCl) to pass through (ratio > 0.4).

- Reject Multivalent Salts: It effectively blocks divalent ions (Calcium, Magnesium) and organics.

Because NF membranes allow monovalent salts to pass, they operate at significantly lower pressures. This makes the NF+RO process ideal for Landfill Leachate, Coal Chemical Wastewater, and Mine Water Treatment. However, these high-difficulty applications make rigorous nanofiltration membrane maintenance even more critical.

4 Common Mistakes in Nanofiltration Membrane Maintenance

Based on field experience at Stark Water, avoiding these four pitfalls is essential for successful nanofiltration membrane maintenance.

1. Improper Shutdown Procedures

The Problem: Failing to flush the system with permeate upon shutdown leaves the membrane soaked in concentrated brine.

The Consequence: High salinity creates an osmotic pressure imbalance, leading to “back-suction” which can peel off the membrane separation layer. This is a catastrophic failure in nanofiltration membrane maintenance.

Stark Water Tip: Always program your PLC to automatically flush with RO product water immediately upon system shutdown.

2. Ignoring Pressure Drop (Delta P)

The Problem: Operating when the pressure difference (Delta P) rises significantly.

Technical Limits: Max pressure drop is 0.69 bar (10 psi) per element or 3.45 bar (50 psi) per vessel.

The Consequence: This causes “telescoping” or cracking of the fiberglass shell. Regular monitoring of Delta P is a non-negotiable part of nanofiltration membrane maintenance.

3. Debris in Piping System

The Problem: PVC shavings or metal filings left in piping during installation.

The Consequence: Under high pressure, debris scratches the membrane surface, causing permanent salt passage. Thorough flushing before installation is a vital step in initial maintenance.

4. Chlorine Oxidation Damage

The Problem: Using tap water with residual chlorine for cleaning.

The Consequence: Polyamide membranes are highly sensitive to oxidation. Chlorine destroys the membrane structure.

Critical Safety Rule: For safe nanofiltration membrane maintenance, ensure feed water ORP is below 200mV. Use 1% Sodium Bisulfite (SBS) to neutralize chlorine if necessary.

Conclusion

Nanofiltration membrane maintenance requires a blend of technical understanding and strict operational discipline. By avoiding these common mistakes—improper shutdowns, ignoring pressure drops, debris damage, and chlorine oxidation—you can maximize your system’s efficiency.

Need Professional Maintenance Support?

Stark Water specializes in high-performance membrane elements and industrial water solutions. Contact us to optimize your nanofiltration membrane maintenance strategy today.