Stark Water Engineering Team | Process Technology Review

Conducting a detailed water treatment process comparison is the first step in designing a successful industrial or municipal plant. Balancing efficiency, cost, and stability requires a deep understanding of the available technologies. According to industry standards, the selection of a treatment process must follow a core principle: technical feasibility combined with economic rationality.

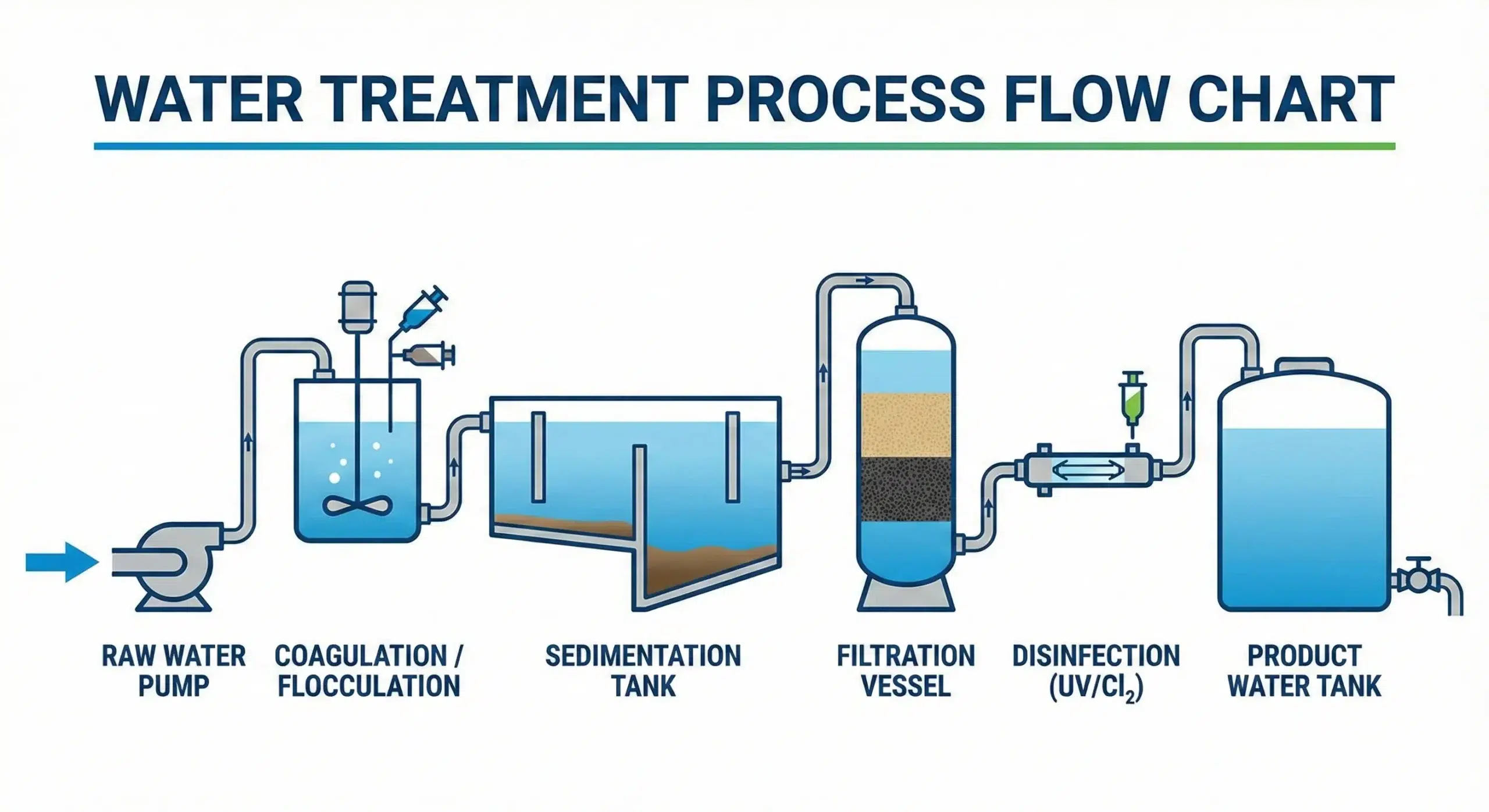

In this water treatment process comparison guide, we break down the standard four-step protocol used to remove turbidity, colloids, and pathogenic microorganisms:

- Coagulation : Destabilizing particles.

- Sedimentation: Separating solids.

- Filtration: Polishing the water.

- Désinfection : Ensuring biological safety.

The following sections provide a side-by-side water treatment process comparison of the dominant technologies available for each step, transforming complex engineering data into clear tables to aid your equipment selection.

Step 1: Coagulation in the Water Treatment Process Comparison

Mixing is the critical first step where coagulants are rapidly dispersed into the water body. When performing a water treatment process comparison for mixing, we look at Pipe Static Mixing versus Mechanical Mixing.

Pipe Mixing vs. Mechanical Mixing Data

| Method | Advantages | Disadvantages | Application Scope |

|---|---|---|---|

| Pipe Static Mixing | 1. Simple equipment, easy management. 2. No civil construction needed. 3. Zero energy consumption (Passive). 4. Excellent mixing at design flow. | 1. Mixing effect fluctuates with flow rate changes. 2. Higher head loss (0.5 – 0.8m). | Plants with stable flow rates. |

| Mechanical Mixing | 1. Superior mixing efficiency. 2. Low head loss. 3. Unaffected by flow rate changes. | 1. High energy consumption. 2. Complex maintenance. 3. Requires a dedicated mixing tank. | Plants dealing with variable flow rates. |

Stark Insight: In our water treatment process comparison, Pipe Static Mixers are often the winner for modular systems due to their compact footprint. Stark Water integrates high-efficiency static mixers in our containerized water treatment plants to reduce maintenance.

Step 2: Sedimentation Tank Types in Water Treatment Process Comparison

After coagulation, the water contains large floc particles. A proper water treatment process comparison must evaluate the footprint efficiency of the sedimentation tank.

Comparison of Sedimentation Technologies

| Type | Advantages | Disadvantages | Suitable Conditions |

|---|---|---|---|

| Horizontal Flow Tank (Rectangular) | 1. Simple structure. 2. Stable treatment effect. 3. Resilient to shock loads. | 1. Massive land footprint required. | Large-scale municipal plants. |

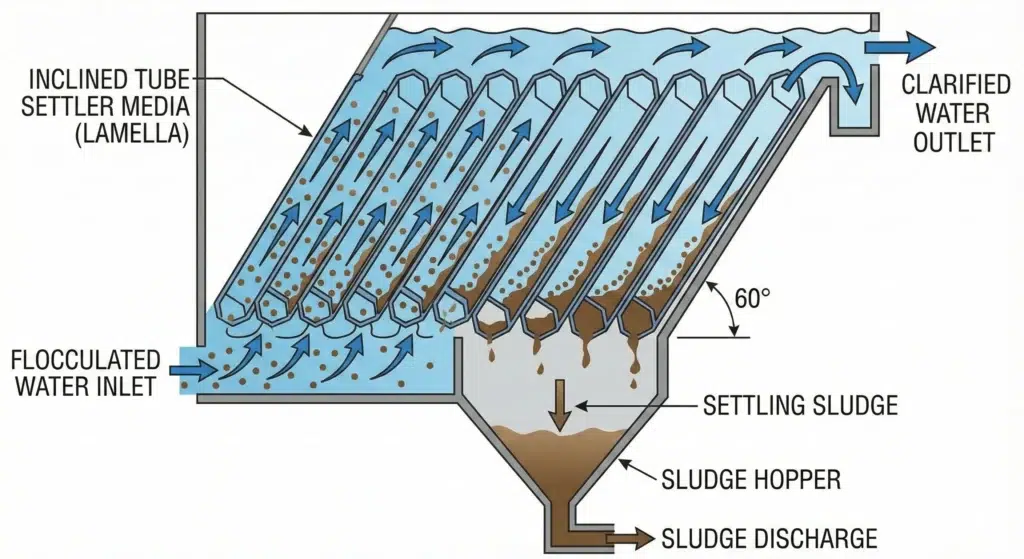

| Inclined Tube Settler (Lamella) | 1. Small footprint. 2. High sedimentation efficiency. 3. Excellent hydraulic conditions. | 1. Material aging (PVC/PP) needs replacement. | Most industrial and commercial water plants. |

| High Density Clarifier | 1. Rapid sludge separation. 2. Small footprint. 3. No sludge thickening required. | 1. High chemical dosage required. | High turbidity or algae loads. |

Step 3: Filtration Technology in Water Treatment Process Comparison

Filtration removes suspended solids that escaped sedimentation. In this water treatment process comparison, we analyze the shift from civil works to pressure vessels.

Rapid Sand Filter vs. V-Type Filter

| Type de filtre | Advantages | Disadvantages | Application |

|---|---|---|---|

| Ordinary Rapid Sand Filter | 1. Reliable operation. 2. Low media cost. 3. Uniform water distribution. | 1. Requires many valves. 2. Complex backwash system. 3. Short filtration cycle. | Small to Medium municipal plants. |

| V-Type Filter | 1. Uniform “V” trough inlet. 2. Air-Water backwash is highly efficient. 3. Long filtration cycle. | 1. Extremely complex civil construction. | Large-scale modern waterworks. |

The Industrial Alternative

For industrial applications where civil work is impractical, our water treatment process comparison favors Stark FRP Pressure Tanks. They offer the efficiency of a Rapid Sand Filter but in a compact, skid-mounted footprint.

Step 4: Disinfection Methods in Water Treatment Process Comparison

Disinfection is the final firewall. The water treatment process comparison below highlights the trade-off between residual protection and safety.

Disinfection Methods Data Table

| Method | Advantages | Disadvantages |

|---|---|---|

| Liquid Chlorine | 1. Continuous residual effect. 2. Low cost. | 1. High safety risk (Toxic gas). 2. Forms byproducts. |

| Sodium Hypochlorite | 1. Safer than Liquid Chlorine. 2. Continuous residual effect. | 1. Higher operating cost. 2. Cannot be stored long-term. |

| Ozone | 1. Strong oxidation. 2. Removes color and odor. | 1. No continuous residual effect. 2. High capital cost. |

| UV Disinfection | 1. Instant kill. 2. No chemical residue. | 1. No continuous residual effect. 2. Requires clear water. |

Conclusion: Finalizing Your Water Treatment Process Comparison

There is no single “best” solution. A proper water treatment process comparison depends on your raw water analysis and budget.

- For Municipal: Concrete V-Type filters and Liquid Chlorine.

- For Industrial: Skid-mounted Stark FRP Tanks and UV systems are preferred.

At Stark Water, we specialize in compact, efficient equipment. If this water treatment process comparison has helped clarify your needs, contact our engineering team to build your custom system.