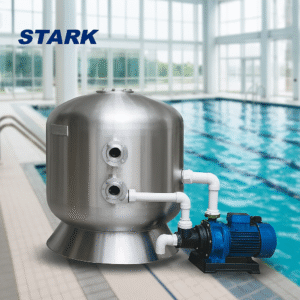

STARK Filtre mécanique en acier inoxydable personnalisé avec vanne électromagnétique

Achieve superior water clarity and protect your systems with Stark Water’s Customized Stainless Steel Mechanical Filter. This robust mechanical filter is expertly designed with stainless steel and an electromagnetic valve for automated, efficient removal of suspended solids, providing a tailored solution for diverse industrial water treatment applications.

Description du produit

Effective pre-filtration is a fundamental and indispensable step in almost every industrial and commercial water treatment process. It serves to protect downstream equipment, ensure consistent water quality, and optimize overall system efficiency. The Stark Water Customized Stainless Steel Mechanical Filter with Electromagnetic Valve is meticulously engineered to excel in this critical role, providing a robust, automated, and highly efficient solution for removing suspended solids and turbidity from various water sources.

The Precision of a Customized Mechanical Filter

Our offering emphasizes a truly customized mechanical filter solution. This means the system is specifically designed to address your unique raw water characteristics, desired filtrate quality, and operational parameters. Key aspects of customization include:

- Filter Media Selection: We can custom-select the optimal granular filter media, such as multi-media (sand, gravel, anthracite), activated carbon, manganese greensand, or specialized resins, to target specific contaminants like suspended solids, turbidity, chlorine, organics, iron, or manganese.

- Capacity & Dimensions: The filter’s size and flow rate are tailored to your exact needs, ensuring efficient processing of your required water volume within your available space.

- Automation Level: The integration of an electromagnetic valve elevates this mechanical filter to an automated system, allowing for programmed backwash and rinse cycles based on time or pressure differential. This hands-free operation minimizes manual intervention and ensures continuous, consistent filtration.

This bespoke approach ensures that your mechanical filter is perfectly optimized for maximum contaminant removal and extended operational lifespan, providing superior clarification and protection for your water systems.

Durable Stainless Steel Construction with Automated Operation

The construction of our mechanical filter from high-grade stainless steel (typically SUS304 or SUS316L) ensures unparalleled durability and hygiene in demanding industrial environments. Stainless steel provides:

- Exceptional Corrosion Resistance: Robust protection against rust, oxidation, and a wide range of water chemistries, including those with varying pH levels or dissolved solids.

- Hygienic Properties: Its smooth, non-porous surface is easy to clean and actively inhibits bacterial growth, making it suitable for applications where cleanliness is paramount, such as in the food & beverage or pharmaceutical industries.

- Structural Integrity: Offers excellent mechanical strength, allowing the filter to withstand high operating pressures and continuous flow, ensuring reliable long-term performance.

The integration of an electromagnetic valve for automatic operation further enhances the system’s reliability and ease of use. This automation significantly reduces labor costs, ensures timely backwashing (critical for maintaining filter efficiency), and prevents human error, maximizing system uptime and filtrate quality. This combination of robust materials and intelligent control makes our mechanical filter a highly dependable and cost-effective solution for various industrial water treatment applications.

Paramètres du produit

Stark Water’s Customized Stainless Steel Mechanical Filter with Electromagnetic Valve is engineered for robust, automated, and efficient water filtration. Here are its key technical specifications:

| Paramètres | Spécifications / Options de personnalisation |

|---|---|

| Concentration sur les mots-clés essentiels | Mechanical Filter design and capabilities. |

| Type de filtre | Mechanical Filter (Pressure Sand Filter, Multi-Media Filter, Activated Carbon Filter, Iron/Manganese Removal Filter). |

| Construction matérielle | High-grade Stainless Steel (SUS304 or SUS316L, specified based on corrosion resistance and application). |

| Valve de contrôle | Automatic control via Electromagnetic Valve. Options for pneumatic/electric actuated valves, or multi-port automatic control valves. |

| Filter Media | Customizable: Quartz Sand, Anthracite, Gravel, Granular Activated Carbon (GAC), Manganese Greensand, Birm, etc. |

| Capacity / Diameter | Customizable, wide range of diameters (e.g., 600mm to 3000mm or more) and heights, based on required flow rate and media volume. |

| Connexions entrée/sortie | Flanged connections (ANSI, DIN, JIS standards), sizes typically from 2″ to 16″ or larger, based on flow rate. |

| Pression de fonctionnement max. Pression de fonctionnement | Typically 0.6 MPa – 1.0 MPa (6 – 10 Bar / 87 – 145 PSI), customizable for higher pressures. |

| Max. Température de fonctionnement | Up to 80°C – 95°C (176°F – 203°F), dependent on internal lining (if any) and sealing materials. |

| Backwash System | Automatic backwash and rinse cycles initiated by pressure differential or time, controlled by electromagnetic valve/actuators. |

| Internal Lining (Optional) | Food-grade epoxy lining or other corrosion-resistant coatings for specific applications. |

| Manholes/Handholes | Top and/or side manholes for media loading/unloading and inspection. |

| Support Type | Skirt support or saddle supports (for horizontal tanks). |

| Surface Finish (External) | Satin polished, brushed, or custom painted. |

| Control System Integration | PLC control with HMI (optional), remote monitoring, and SCADA integration capabilities. |

| Conformité | Designed to meet relevant industry standards (e.g., ASME for pressure vessels, FDA for food contact). |

Industrie concernée

The Stark Water Customized Stainless Steel Mechanical Filter with Electromagnetic Valve is a versatile and essential component for efficient and automated pre-filtration across a broad spectrum of industrial and commercial sectors. Its robust construction and customizable features make it ideal for:

- Industrial Water Treatment Plants: As primary filters (e.g., sand filters) for removing suspended solids, turbidity, and sediment, or as activated carbon filters for removing chlorine and organics, protecting downstream RO systems, UF plants, EDI units, and ion exchange beds.

- Food & Beverage Industry: Essential for clarifying process water, pre-filtration for bottling lines (beer, wine, juices, bottled water), and removing impurities from liquid ingredients, ensuring product clarity, safety, and hygiene.

- Pharmaceutical Industry: Applied in pre-treatment stages for process water systems, removing particulates and safeguarding subsequent purification steps for high-purity water production.

- Power Generation: Critical for pre-treatment of boiler feed water and cooling tower make-up water, preventing scaling, corrosion, and improving overall plant efficiency.

- Municipal Water Treatment: Used for filtering raw surface or well water prior to main disinfection and distribution, improving water clarity and reducing load on subsequent stages.

- Chemical Processing: Filters various chemicals, solvents, and process fluids to remove particulates, chlorine, and organic impurities, protecting pumps and ensuring product purity.

- Wastewater Treatment & Reuse: Employed for primary physical filtration to reduce suspended solids from industrial or municipal wastewater streams before further biological or chemical treatment and for water recycling.

- Electronics & Semiconductor Manufacturing: Provides initial filtration to remove larger particles, protecting sensitive downstream ultra-pure water (UPW) systems.

- Textile & Dyeing Industry: Used for filtering process water and dye baths, removing impurities that could affect fabric quality and color consistency.

- Heating & Cooling Systems: Removing suspended solids from circulating water in large chiller and cooling tower systems to improve heat exchange efficiency and prevent clogging.

Avantage 1

Avantage DEUX

Produits apparentés

Produits similaires

- Produits en acier inoxydable

Carbon Steel Mechanical Filter Housing – Epoxy & Rubber Lined Series (Heavy Duty)

Lire la suite - Produits en acier inoxydable

Stainless Steel Mechanical Filter Housing – Multimedia Sand & Carbon Vessel

Lire la suite

FAQ

Q1 : Quelle est la durée de vie du système d'osmose inverse ?

La durée de vie d'un système d'osmose inverse dépend de la qualité de l'eau et de l'entretien. En règle générale, la membrane dure 2 à 3 ans, tandis que le système lui-même peut durer plus de 10 ans s'il est bien entretenu.

Q2 : Le système peut-il être personnalisé en fonction des différentes conditions de l'eau ?

Oui, tous nos systèmes sont entièrement personnalisables. Nous analysons vos besoins en matière de rapports sur l'eau et d'applications avant de vous proposer des solutions sur mesure.

Q3 : Quelles sont les normes auxquelles répondent les équipements STARK ?

Nos produits sont conformes aux normes CE et ISO 9001 et peuvent être conçus pour répondre à des réglementations régionales spécifiques ou à des normes industrielles sur demande.

Q4 : Quel est le délai de livraison des systèmes STARK RO ?

Les systèmes standard sont expédiés dans un délai de 7 à 15 jours. Pour les commandes personnalisées, le délai peut aller jusqu'à 20-25 jours en fonction de la complexité.

Q5 : Fournissez-vous une assistance technique ou des conseils d'installation ?

Oui. Nous fournissons une documentation technique complète, des conseils à distance par vidéo et nous pouvons envoyer des ingénieurs à l'étranger sur demande.

Q6 : Qu'est-ce qui est inclus dans votre devis ?

Notre devis comprend le système RO complet, le panneau de contrôle, les pompes, les unités de prétraitement et tous les accessoires nécessaires. Les outils d'installation et les pièces de rechange peuvent être inclus sur demande.