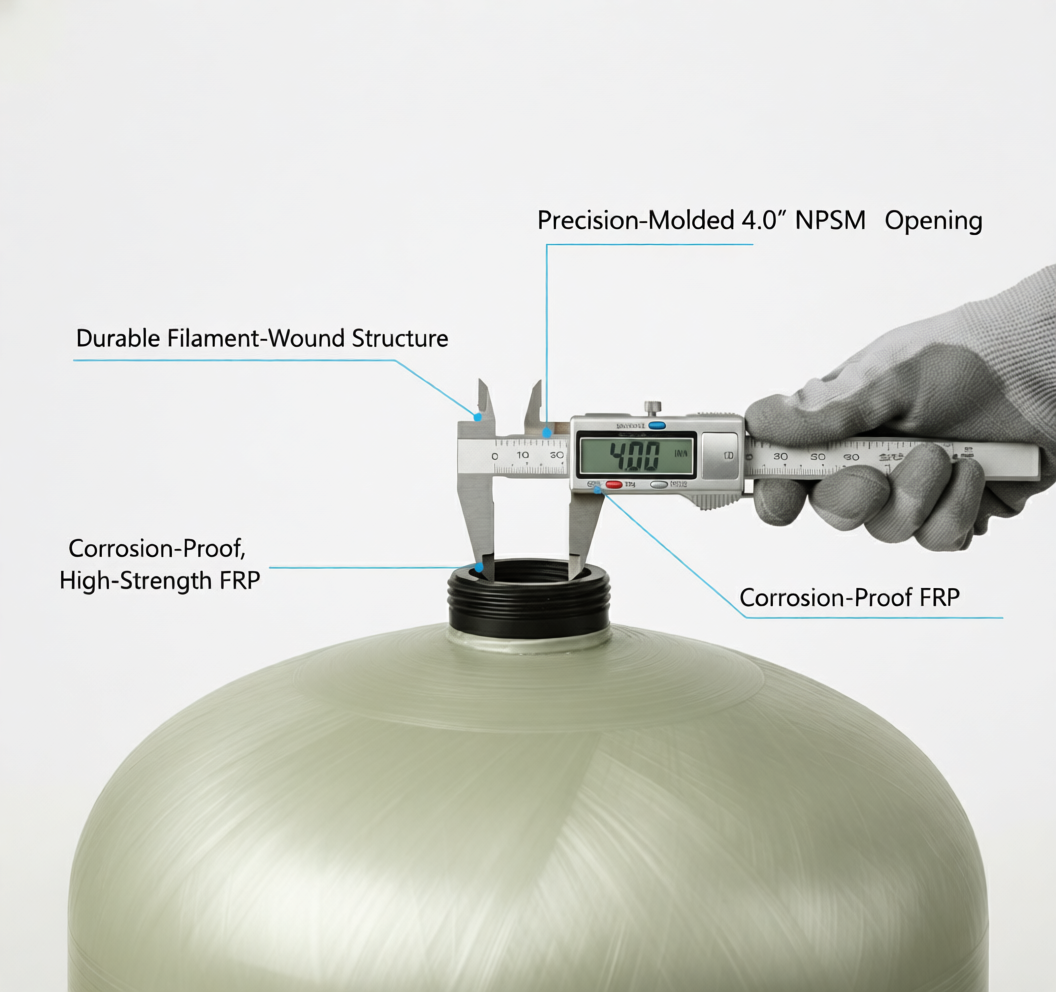

Stark Commercial High-Flow 4 NPSM Pressure Vessel Series

The Stark commercial **4 NPSM pressure vessel** features a wide threaded top opening engineered for high-flow industrial water treatment. This heavy-duty tank eliminates pressure drop bottlenecks and is fully compatible with 1.5″ to 2″ control valves, making it ideal for large-scale boiler feed and hotel water systems.

Product Description

The Industrial Workhorse: High-Flow 4 NPSM Pressure Vessel.

The Stark **4 NPSM pressure vessel** series is designed to meet the rigorous demands of high-volume commercial and industrial applications. As vessel diameter increases (14″ to 36″), standard openings create a “choke point” that restricts flow. Our 4″ NPSM design solves this by providing a significantly larger cross-sectional area, allowing for higher service flow rates and vigorous backwashing of heavy media.

Constructed with a thickened fiberglass winding layer over a seamless PE liner, these tanks offer superior structural integrity to handle the immense weight of large media beds while maintaining a 150 PSI pressure rating.

Engineering Data:

Large-diameter vessels require strict fatigue analysis to ensure safety under load. For cycle pressure test reports, resin loading calculations, and dimensional drawings, please reference the official technical data at our specialized manufacturing division:

Stark Tank Manufacturing – 4″ NPSM Industrial Series Specs

.

Product Parameter

Below are the verified specifications for our 4″ NPSM top-mount series. These high-flow tanks are designed for commercial and industrial applications.

| Model | Volume Capacity | Dimensions (Dia x H) | Flow Rate (m³/h) | B2B Quote | ||

|---|---|---|---|---|---|---|

| Type | US Gal | Liters | Nominal | mm | Range | Action |

| STK-1465 | 38.6 | 146 | 14″ x 65″ | Ø355 x 1670 | 1.2-2.3 | Inquiry |

| STK-1665 | 49.7 | 188 | 16″ x 65″ | Ø400 x 1670 | 1.5-3.8 | Inquiry |

| STK-1865 | 62.9 | 238 | 18″ x 65″ | Ø450 x 1670 | 2.5-4.7 | Inquiry |

| STK-2162 | 83.5 | 316 | 21″ x 62″ | Ø530 x 1780 | 3.0-6.0 | Inquiry |

| STK-2472 | 109.6 | 415 | 24″ x 72″ | Ø600 x 1920 | 4.2-8.4 | Inquiry |

| STK-3072 | 169.1 | 640 | 30″ x 72″ | Ø750 x 1920 | 6.6-13.0 | Inquiry |

| STK-3672 | 264.2 | 1000 | 36″ x 72″ | Ø900 x 2150 | 9.5-19.0 | Inquiry |

*Note: US dimensions are nominal. Flow rates are for reference. Please consult our engineers for precise system design.

Applicable Industry

- Commercial Building Supply:

Centralized water softening for hotels, resorts, and hospitals, supporting high peak-flow demands. - Industrial Boiler Feed:

High-capacity removal of hardness minerals to prevent scaling in industrial boilers and cooling towers. - Large Scale RO Pre-Treatment:

Robust multimedia filtration for commercial Reverse Osmosis systems (1000+ LPH capacity).

Advantage One

Maximized Flow & Low Pressure Drop

The 4″ NPSM top opening is a critical upgrade for commercial systems. By pairing with 1.5″ or 2″ control valves, this series minimizes pressure drop during service flow and ensures sufficient water velocity for backwashing.This is essential for heavy media beds (like Pyrolox or Greensand) that require vigorous expansion to prevent fouling, ensuring your system operates efficiently for years.Advantage TWO

Heavy-Duty Structural Integrity

Larger tank diameters require superior structural reinforcement. Stark 4″ NPSM vessels feature a thickened fiberglass winding layer and a reinforced base design to withstand the static load of tons of filter media.Rated for 150 PSI (10.5 Bar) and cycle-tested for fatigue resistance, these tanks are built to perform reliably in harsh industrial plant environments.Related Products

Related products

FAQ

Q1: How long does the reverse osmosis system last?

The lifespan of a reverse osmosis system depends on water quality and maintenance. Typically, the membrane lasts 2–3 years, while the system itself can last over 10 years with proper care.

Q2: Can the system be customized based on different water conditions?

Yes, all our systems are fully customizable. We analyze your water report and application needs before providing tailored solutions.

Q3: What standards does STARK equipment comply with?

Our products comply with CE, ISO 9001, and can be designed to meet specific regional regulations or industry standards upon request.

Q4: What is the delivery time for STARK RO systems?

Standard systems are shipped within 7–15 days. For customized orders, lead time may extend to 20–25 days depending on complexity.

Q5: Do you provide technical support or installation guidance?

Yes. We provide full technical documentation, remote guidance via video, and can dispatch engineers internationally upon request.

Q6: What is included in your quotation?

Our quotation includes the full RO system, control panel, pumps, pre-treatment units, and all necessary fittings. Installation tools and spare parts can be included upon request.