Last updated: November 7, 2025 · Reading time: 10–14 minutes · Público: UF operators, process engineers, EPCs

This fast, field-tested guide shows when to trigger UF chemical cleaning, which chemistries to use, how to size a compact cleaning skid, and the shortest SOP that works: air-scour + backwash, circulate–soak–circulate, then rinse to conductivity match. Use UF chemical cleaning correctly to restore flux, lower TMP, and protect RO/NF.

What You’re Fighting — Fouling Modes (30-Second Refresher)

- Surface cake / gel layer: suspended solids, iron hydroxides, biofilm; increases hydraulic resistance and TMP.

- Pore blockage / adsorption: fines/precipitates and organics inside pores; often partly irreversible without UF chemical cleaning.

- Oil & grease: even trace oil quickly blinds UF; prevent ingress and clean immediately if detected.

UF Chemical Cleaning Triggers — Objective Criteria

| Indicator | Typical threshold | Notas |

|---|---|---|

| TMP rise (normalized) | ≈ +1.0 bar from clean baseline | Confirm gauges & data quality first |

| Permeate flux drop (normalized) | −25% ~ −35% | Check backwash and CEB history |

| Backwash/CEB effect | No recovery after 1–2 trials | Schedule UF chemical cleaning |

UF Chemical Cleaning Recipes — What They Target

| Foulant | Solution (typical) | Contact time (guide) | Notas |

|---|---|---|---|

| Iron & carbonate scales | 1–2% citric acid ou ~0.2% HCl | 30 min circulation + 60 min soak + 30 min circulation | Citric safer; acid first if iron/scale dominate |

| Organics & biofouling | ~0.1% NaOH + ~0.2% NaOCl | 30 + 60 + 30 min | Respect vendor free-chlorine limits for PVDF/PES; dechlorinate thoroughly |

| Unknown / mixed | Trial small loop; analyze rinse (Fe/organics) | - | Choose safe sequence (acid ↔ alkaline/oxidant) |

Compatibility matters: confirm membrane polymer (PVDF/PES/PTFE), allowable free chlorine, pH range, and temperature with your vendor.

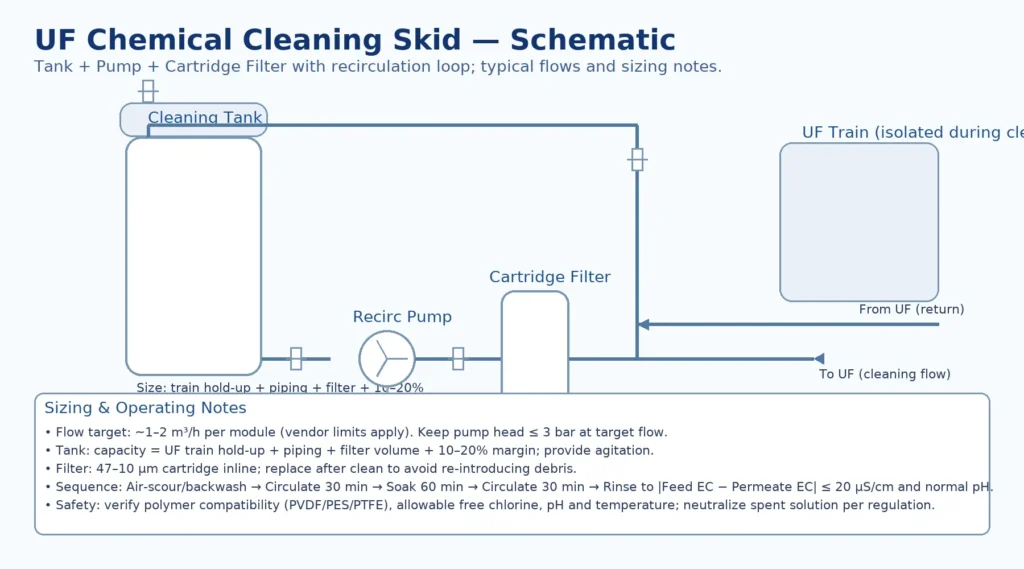

Cleaning Skid — What You Need & How to Size It

- Components: cleaning tank, recirculation pump, cartridge filter (47–10 µm typical), hoses/valves, sampling port.

- Tank volume: hold-up of one UF train + piping + filter volume + 10–20% margin.

- Pump: about 1–2 m³/h per module, head ≤ 3 bar at target flow; stainless steel preferred.

- Filter: rated for chemical and temperature; change out after clean.

Templates & calculators: Ferramentas de água Stark.

UF Chemical Cleaning — 3-Minute Playbook (SOP)

- Prepare — Controlled shutdown; isolate train. Mix solution in the cleaning tank and agitate until uniform.

- Air-scour + water backwash — Run 3–8 cycles × 10–15 s air scours with backwash between cycles until drain runs clear.

- Circulate ① — Open cleaning valves; circulate to tank at ~1 m³/h per module for about 30 min.

- Embeber — Stop pump for ~60 min static contact.

- Circulate ② — Same flow another 30 min; then drain tank and change the cartridge filter if loaded.

- Rinse & acceptance — Flush with clean water until |Feed EC − Permeate EC| ≤ 20 µS/cm (or your site limit) and pH returns to normal; return to service.

Choosing Sequence — Acid First or Alkaline First?

- Start with acid when iron/scale dominate (brown/rusty drain, high Fe in rinse).

- Start with alkaline/oxidant when organics/bio dominate (slimy, UV254/TOC high).

- If unknown, trial a small isolated loop, analyze rinse for Fe/organics, then scale up safely.

- Stay within vendor limits for free chlorine, pH, temperature; neutralize and dispose per local rules.

UF Chemical Cleaning — QA, Safety & Documentation

- Normalization: trend TMP/flux normalized to temperature and pressure; compare pre-/post-clean baselines.

- Records: chemical batch, pH, temperature, contact times, flows, differential pressure, and the conductivity match at acceptance.

- Safety: PPE, ventilation, chemical compatibility checks, dechlorination before discharge.

UF Chemical Cleaning — Troubleshooting

| Sintoma | Likely cause | Next step |

|---|---|---|

| No improvement | Wrong chemistry, insufficient air-scour/contact, low circulation flow | Re-identify foulant; verify flows; repeat with alternate chemistry |

| Partial improvement only | Mixed foulants | Run the second chemistry (acid ↔ alkaline/oxidant) or staged program |

| Rapid re-fouling | Upstream control weak (oil ingress, iron oxidation, high SDI) | Fix pretreatment; adjust flux/backwash/CEB frequency |

References & Further Reading

- U.S. EPA — Water Research

- OSHA — Chemical Hazards & PPE

- ASTM D4189 — Silt Density Index (SDI) Test

- NIOSH — Sodium Hypochlorite Pocket Guide

Visuals & Downloadables

- UF Cleaning Calculator & SOP Checklist (coming soon)

- Water Treatment Solutions - Case Studies - Blogue

- Pedir um orçamento

About the Author

Stark Water — Membrane process engineers specialized in UF chemical cleaning, UF/RO diagnostics and lifecycle-cost optimization.

FAQs — UF Chemical Cleaning

1) CEB vs full chemical clean — what’s the difference?

CEB doses chemicals into backwash for short contact; a full clean uses a separate tank and the circulate–soak–circulate sequence with longer contact.

2) Citric acid or HCl for iron?

Start with 1–2% citric as a safer complexing acid. Use dilute HCl (~0.2%) only when scale is dominant and the vendor allows it.

3) Can I use NaOCl on all UF membranes?

Respect your module’s free chlorine limit and pH window. Many PVDF/PES modules permit low ppm levels for limited time; verify the datasheet.

4) What proves the system is clean?

Normalized TMP near baseline; flux recovery; rinse EC/pH matches feed within your acceptance band (e.g., ≤ 20 µS/cm difference).

5) How often should I plan chemical cleaning?

Only as needed by triggers. If frequency accelerates, fix upstream controls (NTU/SDI, oil ingress, iron oxidation) or reduce flux.