In modern industrial water treatment, the ultrafiltration membrane process stands as a critical barrier against suspended solids, colloids, and microorganisms. Whether used as a pre-treatment for Reverse Osmosis (RO) or as a standalone purification method, the efficiency of a UF system depends heavily on precise process design and operating parameters.

However, simply installing a high-quality ultrafiltration membrane is not enough. Without proper feed water conditioning and parameter control, membranes can suffer from rapid fouling, reducing their lifespan and increasing operational costs.

This guide provides a deep dive into the engineering principles behind the ultrafiltration membrane process, covering pre-treatment standards, SDI calculations, and key operating parameters to ensure your system runs at peak performance.

Why Pre-treatment is Critical for Ultrafiltration Membranes

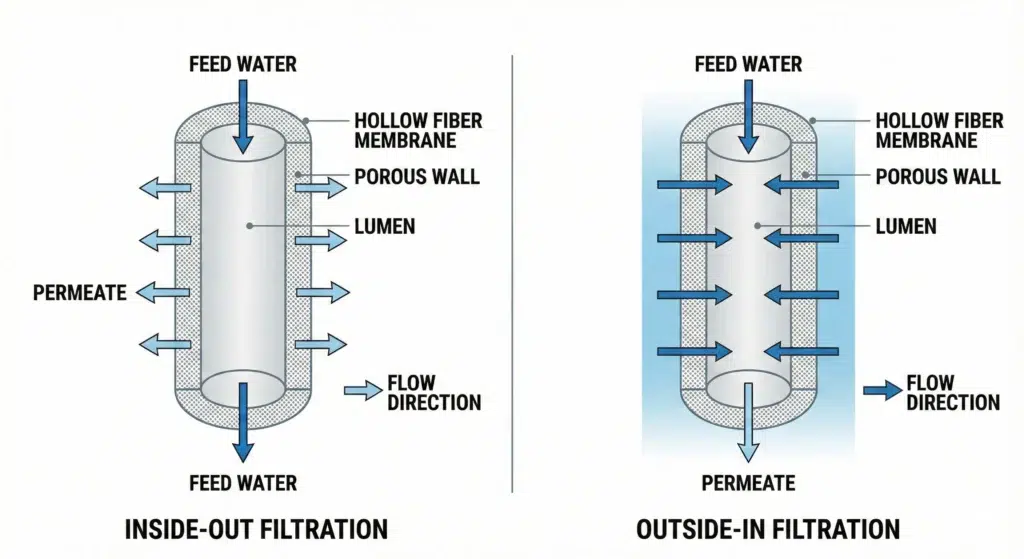

While ultrafiltration is designed to remove impurities, it is not a garbage disposal. The hollow fiber structure of a UF membrane is susceptible to fouling from suspended solids, biological slime, and colloidal particles. The primary goal of pre-treatment is to modify the feed water quality to meet the specific tolerance limits of the membrane material.

Understanding Turbidity and SDI Values

Turbidity measures the cloudiness of water, but it is not precise enough for membrane applications. For the ultrafiltration membrane process, the Silt Density Index (SDI) is the gold standard for predicting fouling potential.

- Well Water: Typically requires an SDI less than 3.

- Surface Water: Often has an SDI greater than 5 and requires rigorous pre-treatment.

- Limit: An SDI greater than 6.66 indicates that the water is too fouled for direct membrane processing.

Pro Tip: How to Calculate SDI

According to ASTM D4189 standards, SDI is calculated using a 0.45μm filter under constant 0.21 MPa pressure. The formula is:

SDI = (1 - t0 / t15) × 100 / 15

Where t0 is the time to filter the initial 500ml, and t15 is the time to filter 500ml after 15 minutes of continuous flow. Stark Water engineers recommend maintaining an SDI of 0 after UF treatment to protect downstream RO systems.

Removing Microorganisms (Bacteria & Algae)

Microorganisms pose a severe threat to hollow fiber UF membranes. If they adhere to the membrane surface, they can multiply and form a biofilm that permanently blocks the pores.

To mitigate this, common industry practices include:

- Oxidation: Dosing NaClO or O3 (1–5 mg/L) into the feed water.

- Sterilization: Regular cycling of Hydrogen Peroxide (H2O2) or Potassium Permanganate for 30–60 minutes during maintenance cleans.

Techniques for Optimizing Feed Water Quality

To ensure the ultrafiltration membrane process operates efficiently, the physical and chemical properties of the feed water must be adjusted.

Coagulation and Flocculation

Standard filters can remove particles larger than 5μm. However, particles between 0.3μm and 5μm—often colloidal—are difficult to trap mechanically. These colloids carry electrostatic charges that keep them suspended.

By adding flocculants (like Polyaluminum Chloride or PAC), we neutralize these charges, causing the particles to clump into larger “flocs” that can be easily filtered out before they reach the delicate UF membrane.

Removing Soluble Organics

It is important to note that ultrafiltration cannot effectively remove soluble organic compounds. If your water analysis shows high organics, we recommend integrating:

- Oxidation: Using Chlorine or KMnO4.

- Adsorption: Utilizing Activated Carbon filters upstream of the UF unit.

Temperature and pH Adjustment

Temperature significantly impacts flux (permeate rate). Generally, for every 1°C increase in temperature, the flux increases by approximately 2.0% due to reduced viscosity.

- Low Temp (< 5°C): Consider heating the feed water to maintain efficiency.

- High Temp: Ensure the temperature does not exceed the membrane’s rating to avoid irreversible damage.

Additionally, check the pH tolerance of your specific membrane. For instance, PVDF hollow fiber membranes typically offer a broad pH tolerance (2–12), whereas Cellulose Acetate membranes are more restricted (pH 4–6).

Key Operating Parameters for UF Systems

Mastering the following parameters is essential for any engineer managing an ultrafiltration membrane process.

1. Flow Rate (Cross-flow Velocity)

The flow velocity across the membrane surface helps scour away retained particles, reducing concentration polarization. For internal pressure hollow fiber membranes, a velocity of roughly 0.1 m/s is often maintained to ensure laminar flow while minimizing pressure drop.

2. Operating Pressure and Pressure Drop

While some external pressure membranes can handle up to 0.6 MPa, standard plastic-shell hollow fiber modules typically operate best below 0.2 MPa.

Maintenance Trigger: Monitor the pressure drop (feed pressure minus concentrate pressure). When the pressure drop increases by 0.05 MPa above the initial startup value, it is time for a chemical clean (CIP).

3. Recovery Ratio and Concentrate Discharge

The recovery ratio (permeate/feed) for industrial UF systems typically ranges from 50% to 90%. Attempting a higher recovery ratio reduces the volume of concentrate (waste) but significantly increases the fouling rate. A balanced design often recycles a portion of the concentrate to maintain high cross-flow velocity without wasting excessive water.

Conclusão

O ultrafiltration membrane process is a balance of hydraulic engineering and chemical water conditioning. By strictly monitoring SDI values, controlling operating pressure, and implementing a robust pre-treatment strategy, you can extend the life of your membranes by years.

At Stark Water, we specialize in high-performance filtration solutions. Whether you need robust PVDF membranes or complete system design advice, our engineers are ready to assist.