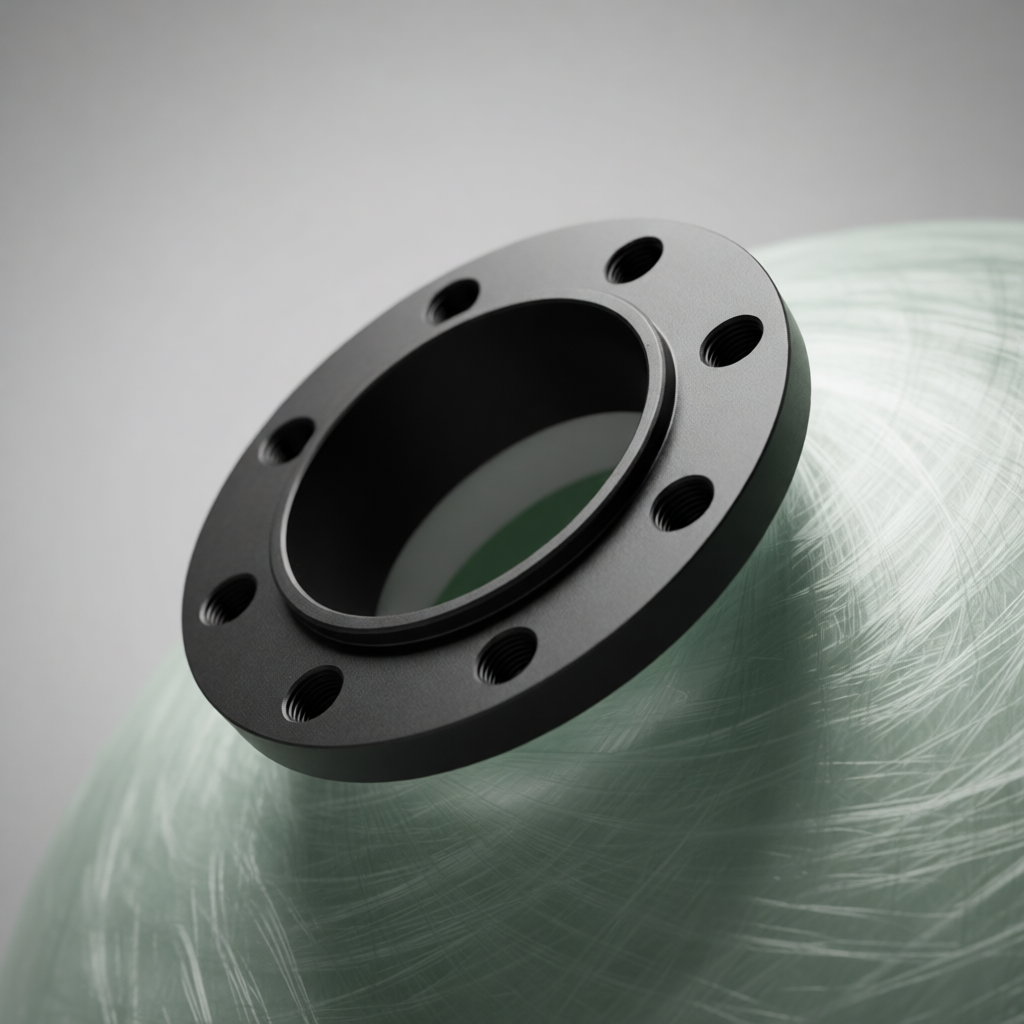

Stark Industrial 6″ Flange Pressure Vessel Series (Heavy Duty)

The Stark industrial **6″ Flange pressure vessel** is engineered for high-volume filtration applications. Featuring a secure 6-inch flange top opening, this heavy-duty tank series (36″-72″ diameter) is designed for municipal water treatment and large-scale industrial plants requiring maximum flow rates and absolutely leak-proof pipe connections.

Descrição do produto

Engineered for the Toughest Industrial Demands.

The Stark **6″ Flange pressure vessel** series represents the pinnacle of large-scale composite manufacturing. Unlike threaded connections which can be prone to leaks under the stress of large piping systems, our 6-inch flange interface offers a robust, bolted connection point compatible with standard DN150 industrial piping. This ensures zero-leakage performance even under high vibration or pressure surges common in desalination plants and municipal facilities.

Our proprietary multi-axis winding process ensures that even our largest 72-inch vessels maintain structural rigidity and uniform pressure distribution, offering a superior, corrosion-resistant alternative to rubber-lined steel tanks.

Installation & Standard Data:

Proper flange alignment and bolt torque are critical for large vessel safety. For detailed flange dimension drawings (ANSI/DIN), bolt circle specifications, and installation torque guides, please reference the technical documentation at our specialized manufacturing division:

Stark Tank Manufacturing – 6″ Flange Series Technical Specs

.

Parâmetro do produto

Below are the verified specifications for our 6″ Flange top-mount series. These heavy-duty tanks are designed for industrial applications requiring high flow rates.

| Modelo | Volume Capacity | Dimensions (Dia x H) | Flow Rate (m³/h) | B2B Quote | ||

|---|---|---|---|---|---|---|

| Tipo | US Gal | Liters | Nominal | mm | (Filter/Softener) | Action |

| STK-3694 | 318.4 | 1205 | 36″ x 94″ | Ø900 x 2465 | 7.6-10 / 12-19 | Inquiry |

| STK-4094 | 351.9 | 1332 | 40″ x 94″ | Ø1000 x 2430 | 9.4-11.7 / 15.7-23.5 | Inquiry |

| STK-4272 | 290.6 | 1100 | 42″ x 72″ | Ø1080 x 1850 | 15-25 / 26-30 | Inquiry |

| STK-4872 | 345.6 | 1308 | 48″ x 72″ | Ø1200 x 1880 | 13.5-17 / 22.6-34 | Inquiry |

| STK-4894 | 504.4 | 1909 | 48″ x 94″ | Ø1200 x 2430 | 13.5-17 / 22.6-34 | Inquiry |

| STK-6083 | 570.1 | 2158 | 60″ x 83″ | Ø1500 x 2120 | 21-27 / 35-53 | Inquiry |

| STK-6094 | 710.2 | 2688 | 60″ x 94″ | Ø1500 x 2430 | 21-27 / 35-53 | Inquiry |

| STK-6383 | 681.6 | 2580 | 63″ x 83″ | Ø1600 x 2100 | 25-45 / 46-56 | Inquiry |

| STK-7294 | 940.8 | 3561 | 72″ x 94″ | Ø1800 x 2400 | 30-40 / 50-76 | Inquiry |

*Note: US dimensions are nominal. Flow rates are for reference only. Please consult our engineers for precise system design.

Setor aplicável

- Municipal Water Treatment:

Large-scale sand and carbon filtration for city water supplies, removing sediment and contaminants at high throughput. - Seawater Desalination:

Pre-treatment filtration for SWRO plants, utilizing corrosion-resistant FRP to withstand aggressive saline environments. - Power Plant Cooling Systems:

Side-stream filtration for cooling towers to reduce suspended solids and prevent heat exchanger fouling.

Vantagem Um

Secure Flange Connection

For vessels exceeding 36 inches in diameter, threaded connections are often insufficient. Stark’s 6-inch flange top opening provides a standardized, bolted connection that eliminates the risk of thread stripping or cross-threading during installation.This design allows for the secure attachment of heavy industrial piping (steel or large diameter UPVC) and ensures a reliable seal capable of withstanding system vibration and hydraulic shock.Vantagem DOIS

Massive Capacity, Minimal Maintenance

With diameters up to 72 inches, these vessels hold thousands of liters of media, allowing for extended service runs between backwashes. Unlike traditional rubber-lined steel tanks, Stark FRP vessels are inherently rust-proof and require zero painting or lining maintenance.This significantly reduces the total cost of ownership (TCO) for large-scale projects while providing a service life that often exceeds 10 years in harsh conditions.Produtos relacionados

Produtos Relacionados

- Acessórios para tratamento de água

Medidor de caudal em plástico e acrílico (rotâmetro) | Stark Water

Ler mais - Acessórios para tratamento de água

Stark LP-4040 Industrial RO Membrane Element (High Flux 5L/min, 99.2% Rejection)

Ler mais

FAQ

Q1: Quanto tempo dura o sistema de osmose inversa?

A vida útil de um sistema de osmose inversa depende da qualidade da água e da manutenção. Normalmente, a membrana dura 2-3 anos, enquanto o sistema em si pode durar mais de 10 anos com os cuidados adequados.

Q2: O sistema pode ser personalizado com base nas diferentes condições da água?

Sim, todos os nossos sistemas são totalmente personalizáveis. Analisamos o seu relatório de água e as necessidades da aplicação antes de fornecer soluções à medida.

Q3: A que normas obedece o equipamento STARK?

Os nossos produtos estão em conformidade com a norma CE, ISO 9001, e podem ser concebidos para cumprir regulamentos regionais específicos ou normas industriais, mediante pedido.

Q4: Qual é o prazo de entrega dos sistemas STARK RO?

Os sistemas standard são enviados no prazo de 7 a 15 dias. Para encomendas personalizadas, o prazo de entrega pode prolongar-se até 20-25 dias, dependendo da complexidade.

Q5: Prestam assistência técnica ou orientação para a instalação?

Sim. Fornecemos documentação técnica completa, orientação remota através de vídeo e podemos enviar engenheiros internacionalmente mediante pedido.

Q6: O que está incluído no vosso orçamento?

O nosso orçamento inclui o sistema RO completo, o painel de controlo, as bombas, as unidades de pré-tratamento e todos os acessórios necessários. As ferramentas de instalação e as peças sobresselentes podem ser incluídas mediante pedido.