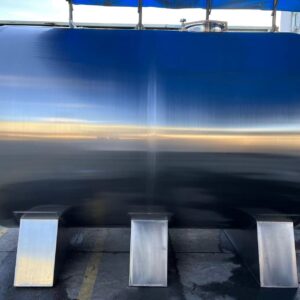

Tanque de água de aço inoxidável personalizado Tanque de água estéril de aço inoxidável de 5000 litros

Secure precise and sterile liquid storage with Stark Water’s Custom Stainless Steel Water Tank. This 5000 litre custom stainless steel water tank is expertly designed as a stainless steel sterile water tank, ensuring the highest levels of hygiene and purity for demanding pharmaceutical, food, and high-purity industrial applications.

Descrição do produto

In industries where product integrity, hygiene, and contamination control are absolutely non-negotiable—such as pharmaceuticals, biotechnology, and specialized food & beverage production—standard storage solutions often fall short. The Custom Stainless Steel Water Tank 5000 litre Stainless Steel Sterile Water Tank from Stark Water is meticulously engineered to address these stringent demands, providing a bespoke, high-purity storage solution that integrates seamlessly into your most critical processes.

Custom Stainless Steel Water Tank: Tailored for Aseptic Excellence

The essence of this product lies in its nature as a custom stainless steel water tank. We understand that every sterile process has unique requirements, from precise dimensions and specific port configurations to specialized surface finishes and automation integration. Our engineering team works closely with you to design and fabricate a tank that perfectly matches your operational needs, ensuring optimal flow dynamics, complete drainability, and minimal contamination risks. This bespoke approach guarantees that the 5000 litre Stainless Steel Sterile Water Tank is not just a container, but a precision instrument vital to maintaining aseptic conditions throughout your process chain.

The 5000 litre capacity makes this tank an ideal choice for medium-to-large scale batch or buffer storage of purified water, active ingredients, or finished products. It provides substantial holding volume while ensuring the highest standards of hygiene and purity.

Uncompromising Purity with Stainless Steel Sterile Water Tank Design

Our commitment to sterile storage is embodied in the meticulous design of this stainless steel sterile water tank. Crafted from high-grade stainless steel (typically SUS304 or SUS316L, chosen for superior corrosion resistance and inertness), every aspect of the tank is optimized for hygiene:

- Mirror-Polished Internal Surfaces: Achieved through meticulous polishing, ensuring a smooth, non-porous finish that actively inhibits microbial adhesion and biofilm formation.

- Crevice-Free Construction: All internal welds are performed to sanitary standards (e.g., orbital welding), eliminating potential harbor points for bacteria and contaminants.

- Aseptic Connections: Equipped with sanitary tri-clamp or similar hygienic connections for all inlets, outlets, and instrumentation ports, preventing external contamination.

- Full Drainability: Often designed with a conical or dished bottom and precise outlet positioning to ensure complete drainage, crucial for effective cleaning-in-place (CIP) and sterilization-in-place (SIP) processes.

- Sterile Venting: Vents are typically fitted with sterile air filters (e.g., 0.22 micron hydrophobic filters) to prevent airborne contamination.

This comprehensive sterile design ensures that the water or liquid stored within maintains its pristine purity, safeguarding product integrity and ensuring full compliance with stringent industry regulations.

Reliability, Compliance, and Seamless Integration

Stark Water’s custom stainless steel water tanks are built for long-term reliability and seamless integration into complex water treatment and production lines. Their robust construction withstands demanding industrial environments, while automated CIP/SIP capabilities simplify cleaning validation and reduce operational downtime. This combination of bespoke design, superior material, and adherence to hygienic standards makes our 5000 litre Stainless Steel Sterile Water Tank a vital asset for maintaining product quality and operational excellence.

Parâmetro do produto

Stark Water’s Custom Stainless Steel Water Tank 5000 litre Stainless Steel Sterile Water Tank is precision-engineered for critical sterile storage applications. Here are its key technical specifications:

| Parâmetro | Especificação / Opções de personalização |

|---|---|

| Foco na palavra-chave principal | conceção e capacidades de reservatórios de água em aço inoxidável personalizados. |

| Capacidade | 5000 Liters (5 m³ / approx. 1321 Gallons). Custom capacities available. |

| Material de construção | Stainless Steel (SUS304 or SUS316L recommended for sterile applications). Specified by client. |

| Tipo de desenho | Vertical Cylindrical, with Dished or Conical Bottom for full drainability. Dished or Conical Top. |

| Acabamento da superfície interna | Espelho polido (por exemplo, Ra < 0,4 μm) para maior higiene e facilidade de limpeza; electropolimento disponível. |

| Acabamento da superfície exterior | Acabamento polido acetinado, acabamento mate ou acabamento #2B. |

| Sterile Features | Sanitary welding (crevice-free), aseptic connections, sterile vent filter port, CIP/SIP spray ball/nozzle. |

| Máx. Pressão de funcionamento | Atmosférica a baixa pressão (por exemplo, 0-0,3 MPa / 0-3 Bar). Concebidos de acordo com os requisitos do cliente. |

| Máx. Temperatura de funcionamento | Designed for sterilization temperatures (e.g., up to 121°C for SIP) or specific process temperatures. |

| Isolamento (opcional) | Espuma de poliuretano ou lã mineral com revestimento exterior de aço inoxidável para controlo térmico. |

| Aquecimento/arrefecimento (opcional) | Jacketed (dimple, coil, or full jacket) or internal coils for temperature control. |

| Agitação (opcional) | Agitadores montados na parte superior ou lateral com selos sanitários para mistura. |

| Ligações/Acessórios | Sanitary Tri-Clamp or DIN/SMS connections for all ports. Includes level sensors, temperature sensors, pressure gauges, sight glass. |

| Pernas de apoio | Pernas ajustáveis em aço inoxidável com almofadas de chão; ou suporte de saia. |

| Conformidade com as normas | Designed and manufactured according to GMP standards, ASME BPE, CE, ISO, FDA (as required by client). |

Setor aplicável

The Custom Stainless Steel Water Tank 5000 litre Stainless Steel Sterile Water Tank is an indispensable asset for industries that require the most stringent levels of hygiene, purity, and contamination control for liquid storage. Its custom design and sterile features make it ideal for a wide range of critical applications:

- Pharmaceutical Industry: Critical for storing Purified Water (PW), Water for Injection (WFI), and Highly Purified Water (HPW) in accordance with GMP guidelines, prior to drug formulation, active pharmaceutical ingredient (API) production, or sterile rinse processes. Also for sterile media and buffer preparations.

- Biotechnology: Essential for sterile storage and processing of cell culture media, buffer solutions, and sensitive biological products that demand aseptic conditions to prevent contamination and ensure product integrity.

- Food & Beverage Industry (Aseptic/High-Purity Lines): Used for sterile storage of purified process water, ingredient water (e.g., for infant formula, specialized beverages), milk, syrups, and other sensitive liquid food products, ensuring safety, extended shelf life, and compliance with sanitary regulations.

- Cosmetics & Personal Care: Provides sterile and hygienic storage for purified water, emulsions, and ingredients used in premium creams, lotions, shampoos, and other personal care products, maintaining product stability and preventing microbial contamination.

- Micro-electronics & Semiconductor Manufacturing: For storing ultra-pure water (UPW) used in critical rinsing, cleaning, and etching processes, where absolute sterility and absence of particulates are essential to prevent defects.

- High-Purity Chemical Manufacturing: Custom tanks for storing specialized, high-purity chemicals where contamination must be avoided and material compatibility is crucial.

- Laboratories & Research Facilities: Custom solutions for storing laboratory-grade water, sterile reagents, or specialized solutions for sensitive experiments, often requiring aseptic conditions.

- Hospitals & Healthcare Facilities: For centralized sterile water storage used in critical applications like instrument reprocessing (though WFI for injection systems would be dedicated).

Vantagem Um

Vantagem DOIS

Produtos relacionados

Produtos Relacionados

- Tanque de água esterilizada

Fornecedor chinês por atacado personalizado 304 tanque de água quente de aço inoxidável

Ler mais

FAQ

Q1: Quanto tempo dura o sistema de osmose inversa?

A vida útil de um sistema de osmose inversa depende da qualidade da água e da manutenção. Normalmente, a membrana dura 2-3 anos, enquanto o sistema em si pode durar mais de 10 anos com os cuidados adequados.

Q2: O sistema pode ser personalizado com base nas diferentes condições da água?

Sim, todos os nossos sistemas são totalmente personalizáveis. Analisamos o seu relatório de água e as necessidades da aplicação antes de fornecer soluções à medida.

Q3: A que normas obedece o equipamento STARK?

Os nossos produtos estão em conformidade com a norma CE, ISO 9001, e podem ser concebidos para cumprir regulamentos regionais específicos ou normas industriais, mediante pedido.

Q4: Qual é o prazo de entrega dos sistemas STARK RO?

Os sistemas standard são enviados no prazo de 7 a 15 dias. Para encomendas personalizadas, o prazo de entrega pode prolongar-se até 20-25 dias, dependendo da complexidade.

Q5: Prestam assistência técnica ou orientação para a instalação?

Sim. Fornecemos documentação técnica completa, orientação remota através de vídeo e podemos enviar engenheiros internacionalmente mediante pedido.

Q6: O que está incluído no vosso orçamento?

O nosso orçamento inclui o sistema RO completo, o painel de controlo, as bombas, as unidades de pré-tratamento e todos os acessórios necessários. As ferramentas de instalação e as peças sobresselentes podem ser incluídas mediante pedido.