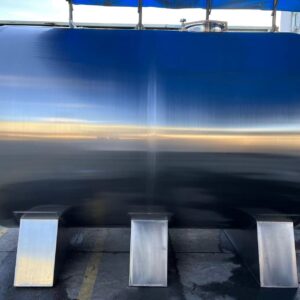

Tanque de água de aço inoxidável 316 com aquecimento personalizado Tanque de água de aço inoxidável com isolamento estéril

Achieve unparalleled purity and precise temperature control with Stark Water’s Customized Heating 316 Stainless Steel Water Tank. This sterile insulation water tank, crafted from premium 316 stainless steel, is custom-engineered for demanding industrial applications requiring hygienic storage and accurate thermal management of sensitive liquids.

Descrição do produto

In industries where product integrity, hygiene, and precise temperature control are non-negotiable—such as pharmaceuticals, biotechnology, and specialized food & beverage production—the quality of liquid storage tanks is paramount. The Stark Water Customized Heating 316 Stainless Steel Water Tank is meticulously engineered to meet these stringent demands, offering a superior solution for storing highly sensitive or temperature-critical liquids under sterile conditions.

The Apex of Material Science: 316 Stainless Steel Water Tank for Unrivaled Purity

The defining feature of this product is its construction from premium 316 stainless steel. While 304 stainless steel offers good general corrosion resistance, 316 stainless steel (specifically 316L for low carbon content, which improves weldability and resistance to intergranular corrosion) provides significantly enhanced resistance to chlorides, acids, and other aggressive chemicals. This makes our 316 stainless steel water tank uniquely suited for storing purified water, pharmaceutical ingredients, sterile solutions, and various process liquids where corrosion can lead to product contamination or material degradation. Its inert nature ensures no leaching into the stored liquid, guaranteeing the highest levels of purity and hygiene. The smooth, non-porous surface of 316 stainless steel actively inhibits microbial adhesion and facilitates thorough cleaning-in-place (CIP) and sterilization-in-place (SIP) processes, crucial for maintaining aseptic conditions.

Customized Heating & Sterile Insulation Water Tank Design

This is more than just a storage vessel; it’s a precisely controlled environment. The tank features fully customized heating capabilities, which can be integrated via heating jackets (dimple, coil, or full jackets for efficient heat transfer), internal heating coils, or electric heating elements. This allows for accurate temperature maintenance, pasteurization, controlled reactions, or prevention of viscosity changes for sensitive products. Complementing the heating, the tank is designed as a sterile insulation water tank. It incorporates high-performance insulation materials (such as polyurethane foam or mineral wool), meticulously clad in an outer stainless steel shell. This insulation minimizes heat loss or gain, drastically reducing energy consumption and ensuring stable temperatures for extended periods. The sterile design principles, including aseptic connections, polished internal finishes, and complete drainability, prevent microbial contamination, safeguarding product integrity from purification through storage.

Bespoke Engineering for Seamless Integration and Performance

Recognizing that every industrial process has unique requirements, our 316 stainless steel water tank is entirely customized. From specific capacities and dimensions to unique connection types, instrumentation ports (for temperature, pressure, level, pH), and agitation systems, every aspect is tailored to your exact operational needs. This bespoke approach ensures seamless integration into your existing production lines, maximizing efficiency, optimizing space utilization, and providing a perfect fit that generic tanks cannot achieve. Its robust construction guarantees durability and reliability, offering a long-term, high-value asset for your critical liquid storage requirements.

Parâmetro do produto

The Stark Water Customized Heating 316 Stainless Steel Water Tank is precision-engineered for critical applications requiring heating, sterility, and insulation. Here are its key technical specifications:

| Parâmetro | Especificação / Opções de personalização |

|---|---|

| Foco na palavra-chave principal | 316 stainless steel water tank design and capabilities. |

| Material de construção | Premium 316 Stainless Steel (typically 316L for low carbon). |

| Capacidade | Personalizável de acordo com os requisitos do cliente (por exemplo, de 100 litros a 50.000 litros ou mais). |

| Método de aquecimento | Customized Heating Jacket (Dimple, Coil, or Full), Internal Heating Coils, or Electric Heating Elements. Designed for steam, hot water/oil, or electricity. |

| Isolamento | Yes, insulated with high-performance materials (Polyurethane Foam, Mineral Wool) and outer stainless steel cladding for thermal efficiency. |

| Tipo de desenho | Vertical or Horizontal, Cylindrical, with dished or conical heads (for complete drainage). |

| Acabamento da superfície interna | Espelho polido (por exemplo, Ra < 0,4 μm) para maior higiene e facilidade de limpeza; electropolimento disponível. |

| Acabamento da superfície exterior | Acabamento polido acetinado, acabamento mate ou acabamento #2B no revestimento exterior. |

| Máx. Pressão de funcionamento | Atmosférico a pressurizado (por exemplo, 0-0,6 MPa / 0-6 Bar), concebido de acordo com os requisitos de pressão do cliente. |

| Gama de temperaturas de funcionamento | Customizable, designed to maintain specific temperatures (e.g., -10°C to 150°C). |

| Agitação (opcional) | Top-mounted or side-mounted agitators with various impeller types for mixing sensitive liquids. |

| Ligações/Acessórios |

|

| Aseptic Features | Sanitary welding, crevice-free design, complete drainability, CIP/SIP compatibility, sterile connections. |

| Conformidade com as normas | Designed and manufactured according to GMP standards, ASME BPE, CE, ISO (as required by client). |

Setor aplicável

The Stark Water Customized Heating 316 Stainless Steel Water Tank is an indispensable and highly adaptable asset for industries where maintaining the highest levels of hygiene, precise temperature control, and sterility is paramount. Its robust 316 stainless steel construction and customizable features make it ideal for a wide range of critical applications:

- Pharmaceutical Industry: Critical for storing and heating Purified Water (PW), Water for Injection (WFI), and Highly Purified Water (HPW), as well as processing and storing sterile solutions, media, and active pharmaceutical ingredients (APIs) under controlled temperatures, strictly adhering to GMP guidelines.

- Biotechnology: Essential for storing and processing sterile buffers, cell culture media, and sensitive biological products that require precise temperature maintenance and aseptic conditions for optimal yield and integrity.

- Food & Beverage Industry (High-Purity/Sterile Lines): Used for hygienic storage and heating/cooling of purified process water, ingredient water (e.g., for infant formula, specialized beverages), milk, syrups, and other temperature-sensitive liquid food products, ensuring safety, taste, and extended shelf life.

- Cosmetics & Personal Care: Provides sterile and temperature-controlled storage for purified water, emulsions, and ingredients used in premium creams, lotions, shampoos, and other personal care products, preserving stability and preventing contamination.

- High-Purity Chemical Processing: For storing and heating/cooling specialized, high-purity chemicals where contamination must be avoided and precise temperature control is vital for reaction kinetics or product stability.

- Laboratories & Research Facilities: Custom tanks for storing temperature-sensitive reagents, culture media, or purified water in large volumes for research and development purposes, often requiring sterile conditions.

- Breweries & Wineries (Specialized): For specific processes requiring precise heating/cooling and hygienic storage of wort, beer, or wine at critical stages, contributing to product consistency and quality.

- Water Treatment Plants (Sterile Process Water): For storing heated, sterile process water used in sensitive downstream applications that demand aseptic conditions.

Vantagem Um

Vantagem DOIS

Produtos relacionados

Produtos Relacionados

-

Tanque de água esterilizada

Fornecedor chinês por atacado personalizado 304 tanque de água quente de aço inoxidável

Adicionar ao orçamento

FAQ

Q1: Quanto tempo dura o sistema de osmose inversa?

A vida útil de um sistema de osmose inversa depende da qualidade da água e da manutenção. Normalmente, a membrana dura 2-3 anos, enquanto o sistema em si pode durar mais de 10 anos com os cuidados adequados.

Q2: O sistema pode ser personalizado com base nas diferentes condições da água?

Sim, todos os nossos sistemas são totalmente personalizáveis. Analisamos o seu relatório de água e as necessidades da aplicação antes de fornecer soluções à medida.

Q3: A que normas obedece o equipamento STARK?

Os nossos produtos estão em conformidade com a norma CE, ISO 9001, e podem ser concebidos para cumprir regulamentos regionais específicos ou normas industriais, mediante pedido.

Q4: Qual é o prazo de entrega dos sistemas STARK RO?

Os sistemas standard são enviados no prazo de 7 a 15 dias. Para encomendas personalizadas, o prazo de entrega pode prolongar-se até 20-25 dias, dependendo da complexidade.

Q5: Prestam assistência técnica ou orientação para a instalação?

Sim. Fornecemos documentação técnica completa, orientação remota através de vídeo e podemos enviar engenheiros internacionalmente mediante pedido.

Q6: O que está incluído no vosso orçamento?

O nosso orçamento inclui o sistema RO completo, o painel de controlo, as bombas, as unidades de pré-tratamento e todos os acessórios necessários. As ferramentas de instalação e as peças sobresselentes podem ser incluídas mediante pedido.