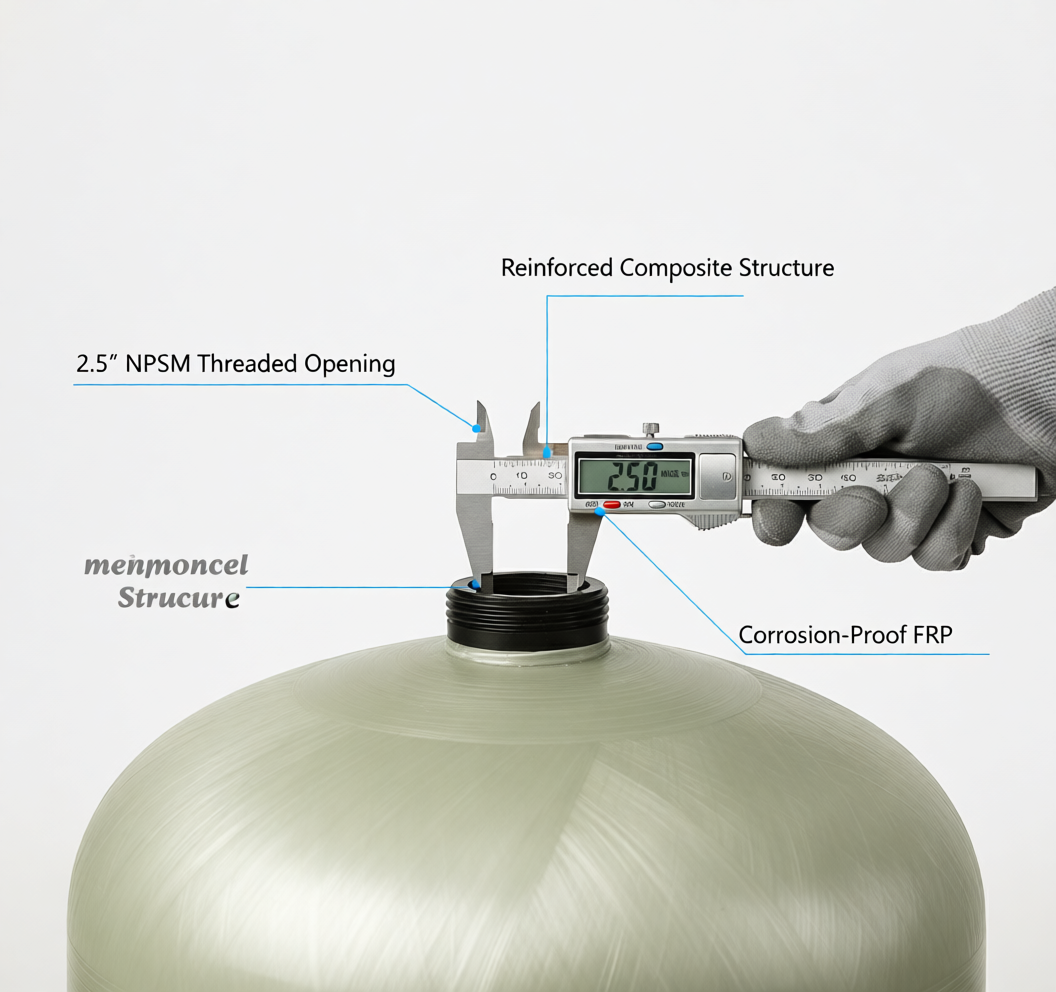

FRP Pressure Vessels – 2.5″ NPSM Series for Water Treatment

High-performance FRP pressure vessel featuring a standard 2.5″ NPSM threaded opening. Designed for residential and light commercial water treatment, this tank is universally compatible with Runxin, Fleck, and Clack control valves, making it the ideal housing for water softeners, carbon filters, and RO pre-treatment systems.

Descrição do produto

The Backbone of Efficient Water Filtration Systems.

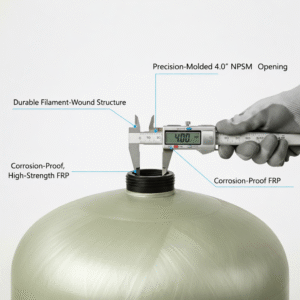

The Stark 2.5″ NPSM Series is our most versatile line of composite fiberglass pressure vessels. Unlike traditional steel tanks that are prone to rust and heavy to handle, our composite vessels feature a seamless high-density polyethylene (HDPE) inner liner wound with continuous fiberglass strands and sealed with high-grade epoxy resin.

This advanced construction ensures 100% corrosion-free performance and zero contamination, making it perfect for drinking water applications and critical RO pre-treatment stages.

Technical Note:

Our tanks undergo rigorous burst pressure and fatigue testing. For detailed structural stress analysis, raw material composition, or specific manufacturing protocols, please reference the official technical data at our specialized manufacturing division:

Stark Tank Manufacturing – 2.5″ NPSM Series Specs

Parâmetro do produto

Use the chart below to select the correct vessel size based on your required resin volume or flow rate.

| Modelo | Volume Capacity | Dimensions (Dia x H) | Flow Rate (m³/h) | B2B Quote | ||

|---|---|---|---|---|---|---|

| Tipo | US Gal | Liters | Inch | mm | Reference | Action |

| STK-713 | 1.6 | 6 | 7″ x 13″ | Ø180 x 335 | 0.3-0.7 | Inquiry |

| STK-717 | 2.4 | 9 | 7″ x 17″ | Ø180 x 430 | 0.3-0.7 | Inquiry |

| STK-735 | 5.3 | 20 | 7″ x 35″ | Ø180 x 905 | 0.3-0.7 | Inquiry |

| STK-817 | 2.9 | 11 | 8″ x 17″ | Ø205 x 445 | 0.3-0.7 | Inquiry |

| STK-835 | 6.3 | 24 | 8″ x 35″ | Ø205 x 905 | 0.3-0.7 | Inquiry |

| STK-844 | 8.7 | 33 | 8″ x 44″ | Ø205 x 1130 | 0.3-0.7 | Inquiry |

| STK-935 | 8.7 | 33 | 9″ x 35″ | Ø230 x 905 | 0.5-1.2 | Inquiry |

| STK-942 | 10.3 | 39 | 9″ x 42″ | Ø230 x 1085 | 0.5-1.2 | Inquiry |

| STK-948 | 11.9 | 45 | 9″ x 48″ | Ø230 x 1230 | 0.5-1.2 | Inquiry |

| STK-1017 | 4.8 | 18 | 10″ x 17″ | Ø255 x 445 | 0.8-1.4 | Inquiry |

| STK-1035 | 10.3 | 39 | 10″ x 35″ | Ø255 x 905 | 0.8-1.4 | Inquiry |

| STK-1044 | 12.9 | 49 | 10″ x 44″ | Ø255 x 1130 | 0.8-1.4 | Inquiry |

| STK-1054 | 16.4 | 62 | 10″ x 54″ | Ø255 x 1390 | 0.8-1.4 | Inquiry |

| STK-1252 | 22.5 | 85 | 12″ x 52″ | Ø300 x 1340 | 0.8-1.5 | Inquiry |

| STK-1265 | 28.0 | 106 | 12″ x 65″ | Ø300 x 1650 | 0.8-1.5 | Inquiry |

| STK-1354 | 27.5 | 104 | 13″ x 54″ | Ø330 x 1400 | 1.2-2.3 | Inquiry |

| STK-1665 | 49.7 | 188 | 16″ x 65″ | Ø400 x 1670 | 1.2-2.3 | Inquiry |

*Flow rates are for reference only. Please consult our engineers for specific system design parameters.

Setor aplicável

- Water Softening Systems:

Ideal housing for cation exchange resin to remove calcium and magnesium hardness in residential and industrial boiler feed water. - Activated Carbon Filtration:

Used for de-chlorination, organics removal, and taste/odor improvement in municipal water supply lines. - RO Pre-Treatment:

Acts as the primary sand/multimedia filter to protect sensitive Reverse Osmosis membranes from sediment and particulate fouling.

Vantagem Um

Corrosion-Resistant Composite Construction

Stark FRP vessels are engineered to outlast traditional steel tanks in aggressive water environments. The inner shell is molded from seamless, food-grade High-Density Polyethylene (HDPE), ensuring that water never touches metal. This guarantees zero rust and no heavy metal leaching.The outer shell is reinforced with continuous strands of fiberglass embedded in high-performance epoxy resin, providing a pressure rating of 150 PSI (10.5 Bar) while being 60% lighter than steel equivalents.Vantagem DOIS

Universal Compatibility & Easy Maintenance

Designed with the system integrator in mind, the 2.5″ NPSM threaded top opening is manufactured with precision tolerances to ensure a leak-free seal with all major control valve brands, including Runxin, Fleck, Clack, and Autotrol.The lightweight composite structure simplifies transport and installation, allowing a single technician to position the tank and load media (Resin, Carbon, or Sand) without the need for heavy lifting equipment.Produtos relacionados

Produtos Relacionados

FAQ

Q1: Quanto tempo dura o sistema de osmose inversa?

A vida útil de um sistema de osmose inversa depende da qualidade da água e da manutenção. Normalmente, a membrana dura 2-3 anos, enquanto o sistema em si pode durar mais de 10 anos com os cuidados adequados.

Q2: O sistema pode ser personalizado com base nas diferentes condições da água?

Sim, todos os nossos sistemas são totalmente personalizáveis. Analisamos o seu relatório de água e as necessidades da aplicação antes de fornecer soluções à medida.

Q3: A que normas obedece o equipamento STARK?

Os nossos produtos estão em conformidade com a norma CE, ISO 9001, e podem ser concebidos para cumprir regulamentos regionais específicos ou normas industriais, mediante pedido.

Q4: Qual é o prazo de entrega dos sistemas STARK RO?

Os sistemas standard são enviados no prazo de 7 a 15 dias. Para encomendas personalizadas, o prazo de entrega pode prolongar-se até 20-25 dias, dependendo da complexidade.

Q5: Prestam assistência técnica ou orientação para a instalação?

Sim. Fornecemos documentação técnica completa, orientação remota através de vídeo e podemos enviar engenheiros internacionalmente mediante pedido.

Q6: O que está incluído no vosso orçamento?

O nosso orçamento inclui o sistema RO completo, o painel de controlo, as bombas, as unidades de pré-tratamento e todos os acessórios necessários. As ferramentas de instalação e as peças sobresselentes podem ser incluídas mediante pedido.