Stark Commercial High-Flow 4 NPSM Pressure Vessel Series

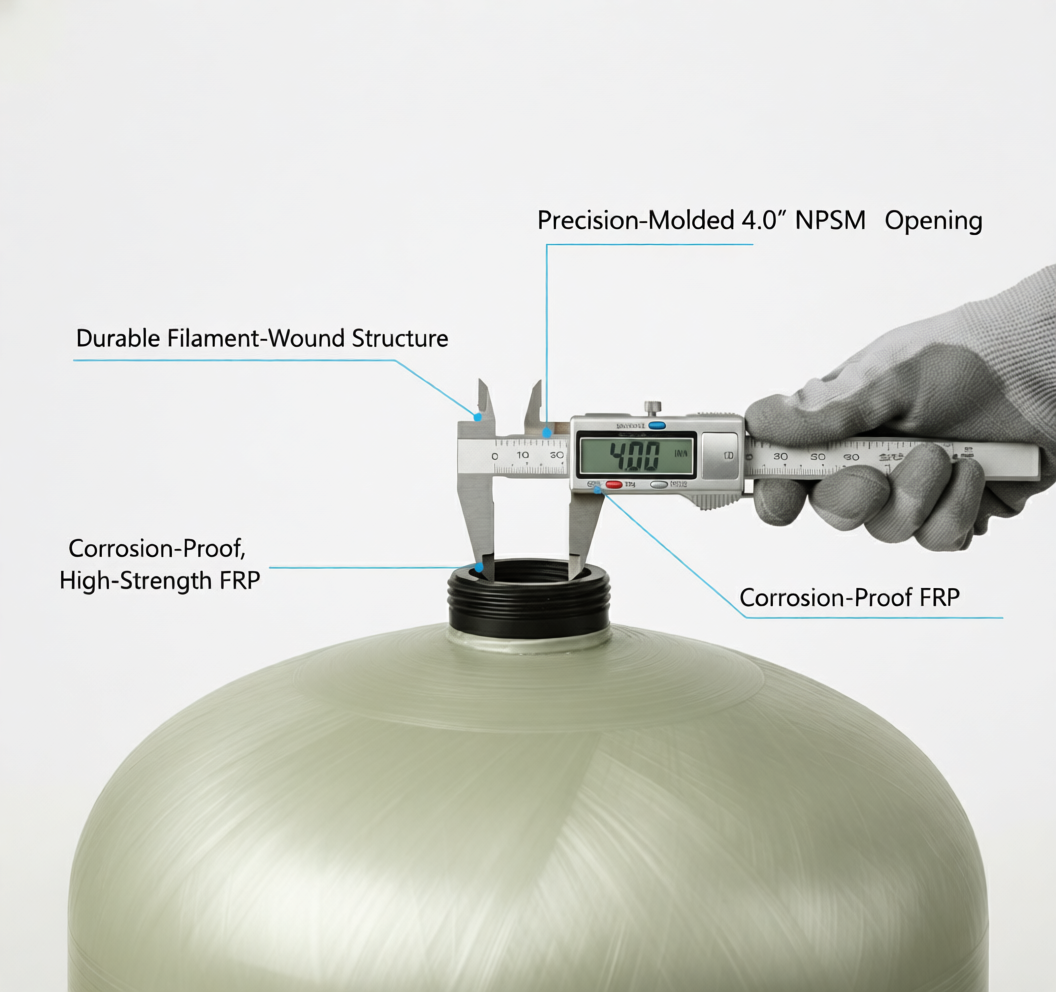

The Stark commercial **4 NPSM pressure vessel** features a wide threaded top opening engineered for high-flow industrial water treatment. This heavy-duty tank eliminates pressure drop bottlenecks and is fully compatible with 1.5″ to 2″ control valves, making it ideal for large-scale boiler feed and hotel water systems.

Descrição do produto

The Industrial Workhorse: High-Flow 4 NPSM Pressure Vessel.

The Stark **4 NPSM pressure vessel** series is designed to meet the rigorous demands of high-volume commercial and industrial applications. As vessel diameter increases (14″ to 36″), standard openings create a “choke point” that restricts flow. Our 4″ NPSM design solves this by providing a significantly larger cross-sectional area, allowing for higher service flow rates and vigorous backwashing of heavy media.

Constructed with a thickened fiberglass winding layer over a seamless PE liner, these tanks offer superior structural integrity to handle the immense weight of large media beds while maintaining a 150 PSI pressure rating.

Engineering Data:

Large-diameter vessels require strict fatigue analysis to ensure safety under load. For cycle pressure test reports, resin loading calculations, and dimensional drawings, please reference the official technical data at our specialized manufacturing division:

Stark Tank Manufacturing – 4″ NPSM Industrial Series Specs

.

Parâmetro do produto

Below are the verified specifications for our 4″ NPSM top-mount series. These high-flow tanks are designed for commercial and industrial applications.

| Modelo | Volume Capacity | Dimensions (Dia x H) | Flow Rate (m³/h) | B2B Quote | ||

|---|---|---|---|---|---|---|

| Tipo | US Gal | Liters | Nominal | mm | Range | Action |

| STK-1465 | 38.6 | 146 | 14″ x 65″ | Ø355 x 1670 | 1.2-2.3 | Inquiry |

| STK-1665 | 49.7 | 188 | 16″ x 65″ | Ø400 x 1670 | 1.5-3.8 | Inquiry |

| STK-1865 | 62.9 | 238 | 18″ x 65″ | Ø450 x 1670 | 2.5-4.7 | Inquiry |

| STK-2162 | 83.5 | 316 | 21″ x 62″ | Ø530 x 1780 | 3.0-6.0 | Inquiry |

| STK-2472 | 109.6 | 415 | 24″ x 72″ | Ø600 x 1920 | 4.2-8.4 | Inquiry |

| STK-3072 | 169.1 | 640 | 30″ x 72″ | Ø750 x 1920 | 6.6-13.0 | Inquiry |

| STK-3672 | 264.2 | 1000 | 36″ x 72″ | Ø900 x 2150 | 9.5-19.0 | Inquiry |

*Note: US dimensions are nominal. Flow rates are for reference. Please consult our engineers for precise system design.

Setor aplicável

- Commercial Building Supply:

Centralized water softening for hotels, resorts, and hospitals, supporting high peak-flow demands. - Industrial Boiler Feed:

High-capacity removal of hardness minerals to prevent scaling in industrial boilers and cooling towers. - Large Scale RO Pre-Treatment:

Robust multimedia filtration for commercial Reverse Osmosis systems (1000+ LPH capacity).

Vantagem Um

Maximized Flow & Low Pressure Drop

The 4″ NPSM top opening is a critical upgrade for commercial systems. By pairing with 1.5″ or 2″ control valves, this series minimizes pressure drop during service flow and ensures sufficient water velocity for backwashing.This is essential for heavy media beds (like Pyrolox or Greensand) that require vigorous expansion to prevent fouling, ensuring your system operates efficiently for years.Vantagem DOIS

Heavy-Duty Structural Integrity

Larger tank diameters require superior structural reinforcement. Stark 4″ NPSM vessels feature a thickened fiberglass winding layer and a reinforced base design to withstand the static load of tons of filter media.Rated for 150 PSI (10.5 Bar) and cycle-tested for fatigue resistance, these tanks are built to perform reliably in harsh industrial plant environments.Produtos relacionados

Produtos Relacionados

- Acessórios para tratamento de água

Stark LP-4040 Industrial RO Membrane Element (High Flux 5L/min, 99.2% Rejection)

Ler mais

FAQ

Q1: Quanto tempo dura o sistema de osmose inversa?

A vida útil de um sistema de osmose inversa depende da qualidade da água e da manutenção. Normalmente, a membrana dura 2-3 anos, enquanto o sistema em si pode durar mais de 10 anos com os cuidados adequados.

Q2: O sistema pode ser personalizado com base nas diferentes condições da água?

Sim, todos os nossos sistemas são totalmente personalizáveis. Analisamos o seu relatório de água e as necessidades da aplicação antes de fornecer soluções à medida.

Q3: A que normas obedece o equipamento STARK?

Os nossos produtos estão em conformidade com a norma CE, ISO 9001, e podem ser concebidos para cumprir regulamentos regionais específicos ou normas industriais, mediante pedido.

Q4: Qual é o prazo de entrega dos sistemas STARK RO?

Os sistemas standard são enviados no prazo de 7 a 15 dias. Para encomendas personalizadas, o prazo de entrega pode prolongar-se até 20-25 dias, dependendo da complexidade.

Q5: Prestam assistência técnica ou orientação para a instalação?

Sim. Fornecemos documentação técnica completa, orientação remota através de vídeo e podemos enviar engenheiros internacionalmente mediante pedido.

Q6: O que está incluído no vosso orçamento?

O nosso orçamento inclui o sistema RO completo, o painel de controlo, as bombas, as unidades de pré-tratamento e todos os acessórios necessários. As ferramentas de instalação e as peças sobresselentes podem ser incluídas mediante pedido.