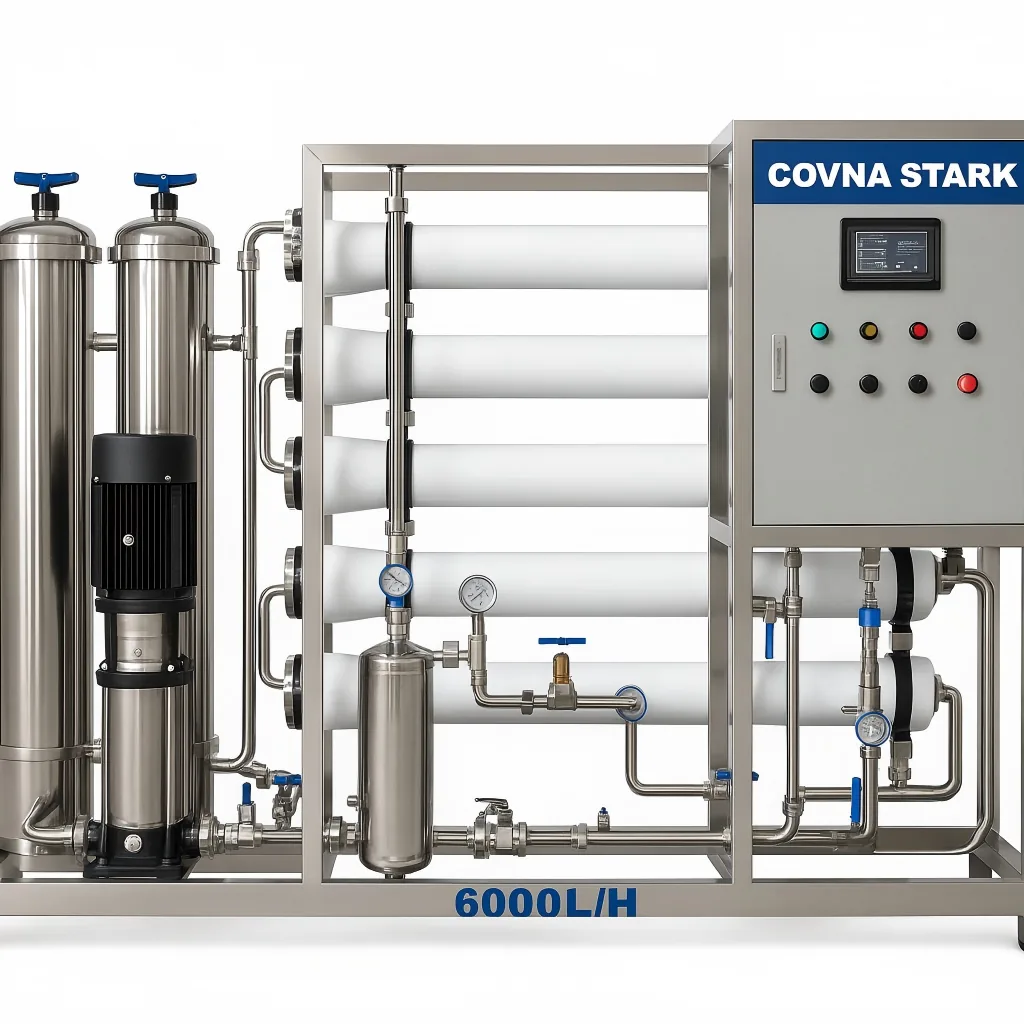

Purificador de água RO 6000LPH, Equipamento de tratamento de água RO com controlo PLC

6000 LPH RO Water Purification System by STARK delivers stable, low-TDS process water for factories, bottling, and commercial buildings. Skid-mounted design with PLC/HMI, auto-flush, and safety interlocks. Recovery engineered to your feedwater. Request a tailored quote.

Descrição do produto

O 6000 LPH RO Water Purification System is engineered for continuous industrial service. Using reverse osmosis membranes, it removes dissolved salts, organics, and particles to produce consistent permeate for boiler make-up, ingredient water, and rinsing lines. A typical train combines multimedia and activated-carbon filtration, a 5 μm cartridge, a stainless-steel high-pressure pump, and automatic flush cycles to reduce fouling. PLC/HMI control with low-/high-pressure interlocks improves reliability and simplifies daily operation. Standard recovery is 60–65% and can be tuned to your feed TDS, SDI, and scaling index. Options include a VFD high-pressure pump, 2-pass RO or RO+EDI for ultra-low conductivity, UV/ozone post-treatment, a CIP package, and remineralization. The compact, skid-mounted layout reduces footprint and service time—helping you deploy a scalable, energy-aware industrial RO system across plants.

Concebido para reliable, 24/7 operation, the STARK 6000 LPH RO system converts municipal or well water into consistently pure process water. A typical process train includes media filtration / activated carbon, cartridge filtration, high-pressure ROe automatic flush sequences to reduce fouling. The compact skid minimizes footprint while providing front-access to pumps, instrumentation, and membranes for fast service.

Why it works: Reverse osmosis uses a semi-permeable membrane to reject dissolved salts, organics, microorganisms, and particulates—delivering permeate that meets downstream needs (boiler makeup, ingredient water, rinsing, etc.). For most industrial sources, 60–65% recovery is a balanced starting point; higher or lower recovery can be engineered based on feed TDS, temperature, SDI, and scaling indices. (STARK provides on-request feedwater testing and sizing.)

Integration & scalability: The system supports options like VFD high-pressure pump, UV/ozone post-treatment, alkalinity re-mineralization, CIP package, or 2-pass RO / EDI when ultra-low conductivity is required. For multi-site rollouts, STARK offers global technical support and spares logistics through our RO product line.

Parâmetro do produto

| Rated Permeate | 6,000 L/h (configurable) |

|---|---|

| Recovery (single-pass) | 60–65% typical; engineered per feed TDS/SDI/LSI |

| Salt Rejection | 96–99% (membrane-dependent) |

| Pré-tratamento | Multimedia → Activated Carbon → 5 μm cartridge |

| Membranas RO | 4″ or 8″ elements (brand per BOM) |

| Bomba de alta pressão | Stainless-steel multistage, VFD optional |

| Control | PLC/HMI, auto-flush, low/high-pressure interlocks |

| Elétrico | 380–415 V/50 Hz or 460 V/60 Hz (site standard) |

| Frame & Piping | Stainless-steel skid, SS/UPVC process lines |

Note: Final values are confirmed after feedwater analysis; STARK provides sizing and testing on request.

Setor aplicável

Food & Beverage — ingredient water, CIP make-up

Bottled Water / Beverage — product & rinse water

Pharma / Cosmetics / Lab — pre-polish for DI/EDI

Electronics & Metal Finishing — low-conductivity rinsing

Commercial & Institutional — hospitals, hotels, campuses

Boiler & Cooling Make-Up — scale/corrosion-controlled supply

Vantagem Um

Advantage 1 — High-Efficiency, Service-Friendly

Compact skid with clear service access

Auto-flush & safety interlocks reduce fouling risk

VFD-ready high-pressure pump for energy optimization

Modular options: CIP, 2-pass, RO+EDI, UV/ozone, remineralization

Vantagem DOIS

Advantage 2 — Consistent Quality & Expert Support

Stable permeate for critical processes

Engineered recovery to balance water cost vs. fouling

Global spares & remote guidance from STARK

Proven architecture for scalable deployments

Produtos relacionados

Produtos Relacionados

- Sistema de osmose inversa

Stark pequeno 500 LPH sistema de filtros de osmose inversa manual máquina de purificação de água

Ler mais - Sistema de osmose inversa

sistemas de purificação de água osmose inversa RO Pure Water Treatment

Ler mais

FAQ

Q1: Quanto tempo dura o sistema de osmose inversa?

A vida útil de um sistema de osmose inversa depende da qualidade da água e da manutenção. Normalmente, a membrana dura 2-3 anos, enquanto o sistema em si pode durar mais de 10 anos com os cuidados adequados.

Q2: O sistema pode ser personalizado com base nas diferentes condições da água?

Sim, todos os nossos sistemas são totalmente personalizáveis. Analisamos o seu relatório de água e as necessidades da aplicação antes de fornecer soluções à medida.

Q3: A que normas obedece o equipamento STARK?

Os nossos produtos estão em conformidade com a norma CE, ISO 9001, e podem ser concebidos para cumprir regulamentos regionais específicos ou normas industriais, mediante pedido.

Q4: Qual é o prazo de entrega dos sistemas STARK RO?

Os sistemas standard são enviados no prazo de 7 a 15 dias. Para encomendas personalizadas, o prazo de entrega pode prolongar-se até 20-25 dias, dependendo da complexidade.

Q5: Prestam assistência técnica ou orientação para a instalação?

Sim. Fornecemos documentação técnica completa, orientação remota através de vídeo e podemos enviar engenheiros internacionalmente mediante pedido.

Q6: O que está incluído no vosso orçamento?

O nosso orçamento inclui o sistema RO completo, o painel de controlo, as bombas, as unidades de pré-tratamento e todos os acessórios necessários. As ferramentas de instalação e as peças sobresselentes podem ser incluídas mediante pedido.