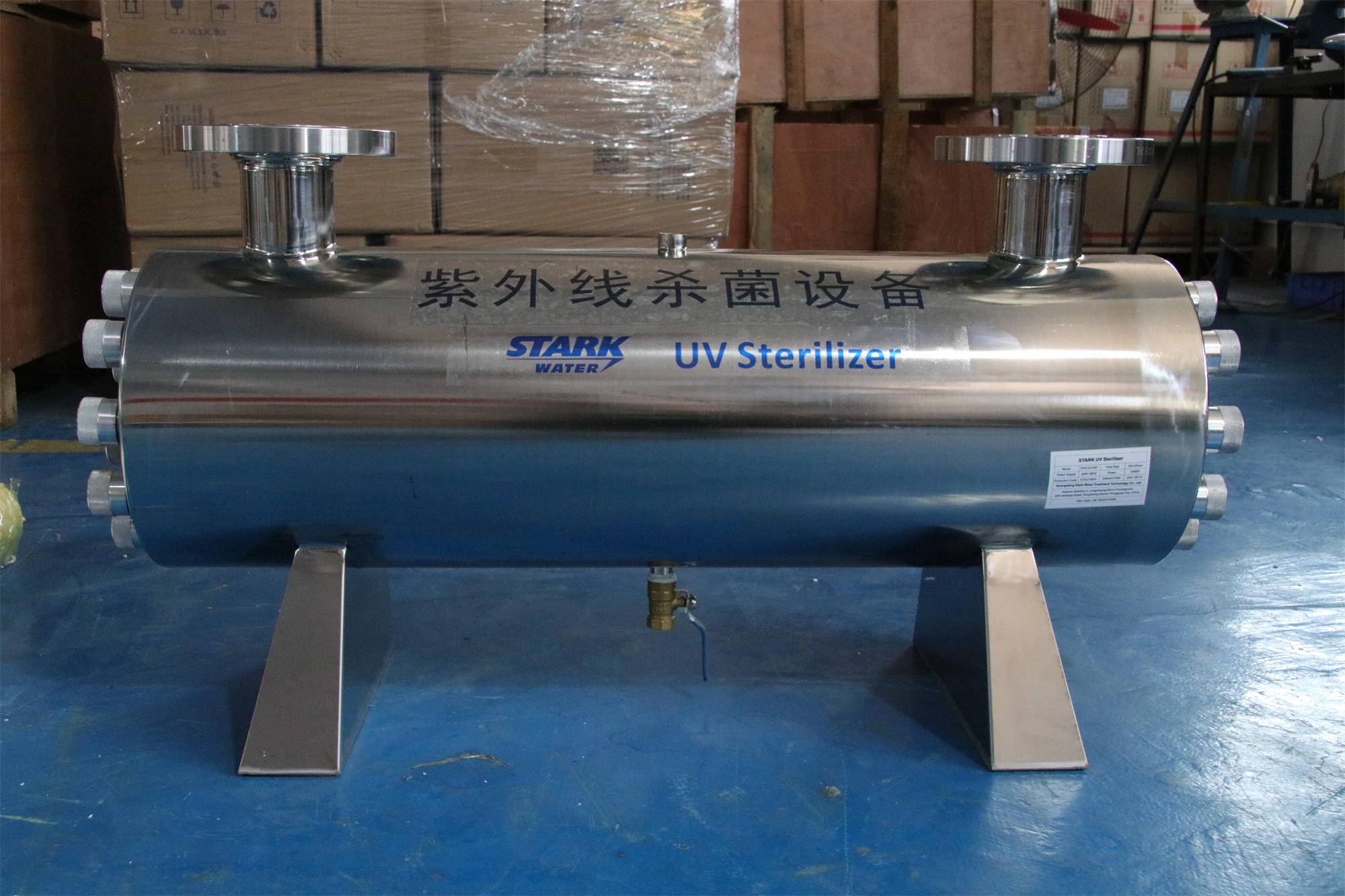

STK Esterilizador ultravioleta grande Esterilizador UV Esterilizador de água uv

Ensure chemical-free and highly effective water disinfection with Stark Water’s STK Large Ultraviolet Sterilizer. This powerful UV sterilizer provides robust UV water sterilization, designed for high-volume industrial, commercial, and municipal applications demanding superior pathogen inactivation and pure water.

Descrição do produto

Achieving microbiological safety in water without introducing chemicals is a paramount concern for a vast array of industries, municipalities, and commercial establishments. The Stark Water STK Large Ultraviolet Sterilizer offers a cutting-edge and highly effective solution, leveraging the power of UV-C light to provide robust disinfection for high-volume water flows. This advanced UV sterilizer is an indispensable component in modern water treatment plants, ensuring unparalleled purity and safety.

Large Ultraviolet Sterilizer: Chemical-Free Water Disinfection

Our STK Large Ultraviolet Sterilizer is specifically engineered for substantial flow rates, utilizing high-output UV lamps to deliver a powerful UV-C dose across large volumes of water. The core principle of this UV water sterilizer is straightforward yet incredibly effective: as water passes through the UV reactor chamber, ultraviolet light (specifically at the germicidal wavelength of 254 nm) directly attacks the DNA and RNA of bacteria, viruses, molds, yeasts, and other microorganisms. This renders them unable to reproduce and effectively inactivates them, preventing them from causing illness or spoilage. The key advantages of this chemical-free process include:

- No Chemical Residuals: UV disinfection does not add any chemicals to the water, eliminating concerns about harmful disinfection byproducts (DBPs) or changes in water taste, odor, or pH.

- Immediate Effect: Inactivation of microorganisms occurs instantly as water passes through the UV chamber, requiring no contact time or storage tanks.

- Effective Against Chlorine-Resistant Pathogens: Highly effective against pathogens like Cryptosporidium and Giardia, which are resistant to traditional chlorine disinfection.

- Environmentally Friendly: A sustainable method that does not generate hazardous waste or contribute to chemical pollution.

Its large-scale design ensures high throughput while maintaining the necessary UV dose for comprehensive pathogen inactivation, critical for municipal water supplies and industrial processes.

Robust UV Sterilizer for Diverse Water Treatment Needs

The STARK Large Ultraviolet Sterilizer is constructed with durability and reliability in mind. The UV reactor chamber is typically made from high-grade stainless steel (e.g., SUS304 or SUS316L) to ensure corrosion resistance and optimal UV transmittance. It houses high-quality UV lamps (often low-pressure or medium-pressure mercury lamps) protected by quartz sleeves, allowing for efficient light penetration into the water. Designed for continuous operation, this UV water sterilizer is equipped with intelligent monitoring systems for UV lamp status, intensity, and alarm functions, simplifying operation and ensuring consistent disinfection performance. It serves as a vital final disinfection step in drinking water systems, a crucial component for water reuse applications, and an effective purification stage in various industrial processes.

Parâmetro do produto

| Parâmetro | Especificação / Opções de personalização |

|---|---|

| Foco na palavra-chave principal | UV Sterilizer design and capabilities. |

| Capacidade de tratamento | Customizable, ranging from 10 m³/hr to 1000+ m³/hr (approx. 44 GPM to 4400+ GPM), depending on application and UV dose requirements. |

| UV Lamp Type | High-output Low-Pressure (LP) UV lamps or Medium-Pressure (MP) UV lamps. Lifespan typically 9,000 to 16,000 hours. |

| UV Dose (Minimum) | Standard 30 mJ/cm² or 40 mJ/cm² (for drinking water disinfection). Higher doses available for specific pathogens or applications. |

| UV Reactor Material | Stainless Steel (SUS304 or SUS316L recommended for superior corrosion resistance). |

| Ligações de entrada/saída | Flanged connections (ANSI, DIN, JIS standards), sizes from 2″ to 24″ or larger, based on flow rate. |

| Máx. Pressão de funcionamento | Typically 1.0 MPa (10 Bar / 145 PSI), customizable for higher pressures. |

| Máx. Temperatura de funcionamento | 5°C - 45°C (41°F - 113°F). |

| Sistema de controlo | Integrated control panel with lamp status indicators, UV intensity monitor, hour meter, alarm indicators (lamp failure, high temp), automatic cleaning system (optional). PLC control and remote monitoring available. |

| Fonte de alimentação | 3 fases, 380V/415V/460V, 50Hz/60Hz (personalizável de acordo com as normas regionais). |

| Lamp Configuration | Multiple UV lamps arranged in parallel for optimal flow distribution and UV dosage uniformity. |

| Cleaning System (Optional) | Manual or automatic (mechanical/chemical) wiping systems for quartz sleeves. |

| Conformidade | Designed to meet industry standards for UV disinfection (e.g., USEPA UV Disinfection Guidance Manual). |

Setor aplicável

- Municipal Drinking Water Treatment: Provides final disinfection for drinking water supplies, effectively eliminating bacteria, viruses, and chlorine-resistant pathogens like Cryptosporidium and Giardia before distribution to communities.

- Food & Beverage Industry: Ensures microbiological safety for process water, rinse water, and final product water in bottling plants, breweries, dairies, and food processing facilities, without altering taste or composition.

- Pharmaceutical & Medical Industry: Utilized for disinfecting Purified Water (PW) and as a polishing step for Water for Injection (WFI) loops, ensuring critical water quality for drug manufacturing, medical device sterilization, and laboratory use, adhering to GMP standards.

- Wastewater Treatment & Reuse: Provides effective disinfection of treated municipal or industrial wastewater effluent, making it safe for discharge into the environment or for various water reuse applications (e.g., irrigation, industrial process water, cooling tower make-up).

- Swimming Pools & Spas: Reduces reliance on chemical disinfectants, minimizes irritating chloramines, and provides superior pathogen inactivation for healthier swimming environments.

- Aquaculture & Fisheries: Sterilizes water in fish farms, hatcheries, and aquariums, preventing disease outbreaks and maintaining optimal water quality for aquatic life.

- Cooling Tower Disinfection: Controls microbial growth in cooling tower recirculation water, preventing biofouling, reducing chemical usage, and improving heat exchange efficiency.

- Electronics & Semiconductor Manufacturing: Used as a final disinfection step in ultra-pure water (UPW) systems, ensuring complete microbial inactivation for sensitive manufacturing processes.

- Cosmetics & Personal Care: Disinfects process water and ingredients, ensuring product purity and consumer safety.

- Agricultural Applications: For disinfecting irrigation water for high-value crops or water used for livestock, preventing pathogen transmission.

Vantagem Um

Vantagem DOIS

Produtos relacionados

Produtos Relacionados

FAQ

Q1: Quanto tempo dura o sistema de osmose inversa?

A vida útil de um sistema de osmose inversa depende da qualidade da água e da manutenção. Normalmente, a membrana dura 2-3 anos, enquanto o sistema em si pode durar mais de 10 anos com os cuidados adequados.

Q2: O sistema pode ser personalizado com base nas diferentes condições da água?

Sim, todos os nossos sistemas são totalmente personalizáveis. Analisamos o seu relatório de água e as necessidades da aplicação antes de fornecer soluções à medida.

Q3: A que normas obedece o equipamento STARK?

Os nossos produtos estão em conformidade com a norma CE, ISO 9001, e podem ser concebidos para cumprir regulamentos regionais específicos ou normas industriais, mediante pedido.

Q4: Qual é o prazo de entrega dos sistemas STARK RO?

Os sistemas standard são enviados no prazo de 7 a 15 dias. Para encomendas personalizadas, o prazo de entrega pode prolongar-se até 20-25 dias, dependendo da complexidade.

Q5: Prestam assistência técnica ou orientação para a instalação?

Sim. Fornecemos documentação técnica completa, orientação remota através de vídeo e podemos enviar engenheiros internacionalmente mediante pedido.

Q6: O que está incluído no vosso orçamento?

O nosso orçamento inclui o sistema RO completo, o painel de controlo, as bombas, as unidades de pré-tratamento e todos os acessórios necessários. As ferramentas de instalação e as peças sobresselentes podem ser incluídas mediante pedido.