Industrial & Commercial Water Treatment Systems Manufacturer | Stark Water

معدات معالجة المياه

- حلول هندسية مصممة خصيصًا

نحن نقدم أنظمة معالجة مياه مخصصة بالكامل مصممة لتلبية متطلبات العملية الخاصة بك، وقيود المساحة والمعايير الإقليمية. - ضمان لمدة 18 شهرًا ودعم فني مدى الحياة

تتضمن كل عملية شراء ضمان جودة لمدة 18 شهراً ودعماً مدى الحياة. - تدريب مجاني على التركيب في الموقع

يتم تقديم إرشادات التركيب والتشغيل مجاناً. - العبوات من فئة التصدير قياسية

جميع المعدات معبأة بإطار خشبي وفقًا لمعايير التصدير مجانًا. - خدمات التصدير والتوصيل الشاملة

نحن نقدم الدعم الكامل لكل من شحنات LCL و FCL، بما في ذلك خدمات تحميل الحاويات المجانية في منشأتنا. بالنسبة للطلبات المحلية داخل المقاطعة، تتوفر خدمة التوصيل المجاني. جميع الخدمات اللوجستية مدعومة بالوثائق المناسبة والتنسيق في الوقت المناسب. - وعدنا: شراكة طويلة الأمد

يمثل طلبك بداية التزامنا وليس نهايته. نحن ننمو مع عملائنا في كل خطوة على الطريق.

لماذا تشوس كوفنا ستارك

قطع غيار معالجة المياه

أكثر من 200 شهادة براءة اختراع

عرض المزيد من المنتجات

أدلة معالجة المياه الصناعية

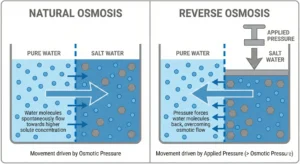

How to Improve Reverse Osmosis System Durability: Practical Methods and Best Practices

اقرأ المزيد "

يناير 19, 2026

أدلة معالجة المياه الصناعية

Beyond Filtration: The Engineering Logic and Working Principle of Industrial Reverse Osmosis Systems

اقرأ المزيد "

ديسمبر 23, 2025