Industrial & Commercial Water Treatment Systems Manufacturer | Stark Water

Оборудование для очистки воды

- Индивидуальные инженерные решения

Мы предлагаем полностью индивидуальные системы водоподготовки, разработанные с учетом специфических технологических требований, ограничений по площади и региональных стандартов. - Гарантия 18 месяцев и пожизненная техническая поддержка

На каждую покупку предоставляется 18-месячная гарантия качества и пожизненная поддержка. - Бесплатное обучение установке на месте

Руководство по установке и вводу в эксплуатацию предоставляется бесплатно. - Упаковка экспортного класса является стандартной

Все оборудование бесплатно упаковывается в деревянную раму в соответствии с экспортным стандартом. - Комплексные услуги по экспорту и доставке

Мы предлагаем полную поддержку как LCL, так и FCL, включая бесплатные услуги по погрузке контейнеров на нашем предприятии. Для внутренних заказов в пределах провинции предусмотрена бесплатная доставка. Вся логистика обеспечивается надлежащей документацией и своевременной координацией. - Наше обещание: долгосрочное партнерство

Ваш заказ - это начало, а не конец наших обязательств. Мы растем вместе с нашими клиентами на каждом шагу.

Почему Хоссе Ковна Старк

Детали для очистки воды

200+ патентных свидетельств

Посмотреть другие товары

Руководства по промышленной водоподготовке

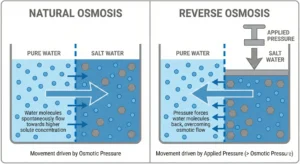

How to Improve Reverse Osmosis System Durability: Practical Methods and Best Practices

Читать далее "

Январь 19, 2026

Руководства по промышленной водоподготовке

Beyond Filtration: The Engineering Logic and Working Principle of Industrial Reverse Osmosis Systems

Читать далее "

Декабрь 23, 2025