Industrial & Commercial Water Treatment Systems Manufacturer | Stark Water

Waterbehandelingsapparatuur

- Engineering-oplossingen op maat

We bieden volledig op maat gemaakte waterbehandelingssystemen die zijn ontworpen om te voldoen aan uw specifieke procesvereisten, ruimtebeperkingen en regionale normen. - 18 maanden garantie & levenslange technische ondersteuning

Bij elke aankoop krijg je 18 maanden kwaliteitsgarantie en levenslange ondersteuning. - Gratis installatietraining op locatie

Begeleiding bij installatie en inbedrijfstelling is gratis. - Standaard exportverpakking

Alle apparatuur wordt gratis ingepakt met een houten frame volgens de exportnorm. - Uitgebreide export- en leveringsdiensten

We bieden volledige ondersteuning voor zowel LCL- als FCL-zendingen, inclusief gratis containerladen op onze vestiging. Voor binnenlandse bestellingen binnen de provincie is gratis levering beschikbaar. Alle logistiek wordt ondersteund met de juiste documentatie en tijdige coördinatie. - Onze belofte: langdurig partnerschap

Je bestelling is het begin - niet het einde - van onze toewijding. We groeien samen met onze klanten, bij elke stap.

Waarom kiezen voor Covna Stark

Waterbehandelingsonderdelen

200+ Octrooicertificaten

Bekijk meer product

Gidsen voor industriële waterbehandeling

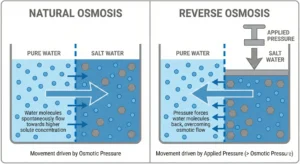

Beyond Filtration: The Engineering Logic and Working Principle of Industrial Reverse Osmosis Systems

Read More "

december 23, 2025