Industrial & Commercial Water Treatment Systems Manufacturer | Stark Water

Equipos de tratamiento de agua

- Soluciones de ingeniería a medida

Ofrecemos sistemas de tratamiento de agua totalmente personalizados, diseñados para satisfacer los requisitos específicos de su proceso, las limitaciones de espacio y las normas regionales. - Garantía de 18 meses y asistencia técnica de por vida

Cada compra incluye una garantía de calidad de 18 meses y asistencia de por vida. - Formación gratuita sobre instalación in situ

La instalación y la puesta en marcha son gratuitas. - Embalaje estándar para la exportación

Todos los equipos se embalan gratuitamente con un marco de madera conforme a la norma de exportación. - Servicios integrales de exportación y entrega

Ofrecemos asistencia completa tanto para envíos LCL como FCL, incluidos servicios gratuitos de carga de contenedores en nuestras instalaciones. Para pedidos nacionales dentro de la provincia, la entrega es gratuita. Toda la logística está respaldada con la documentación adecuada y la coordinación oportuna. - Nuestra promesa: asociación a largo plazo

Su pedido marca el principio, no el final, de nuestro compromiso. Crecemos con nuestros clientes, en cada paso del camino.

Por qué elegir Covna Stark

Piezas para el tratamiento del agua

Más de 200 certificados de patentes

Ver más productos

Guías para el tratamiento de aguas industriales

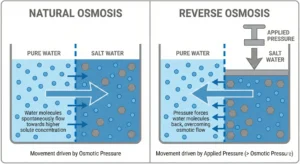

Beyond Filtration: The Engineering Logic and Working Principle of Industrial Reverse Osmosis Systems

Leer Más "

diciembre 23, 2025