Industrial & Commercial Water Treatment Systems Manufacturer | Stark Water

Peralatan Pengolahan Air

- Solusi Rekayasa yang Disesuaikan

Kami menawarkan sistem pengolahan air yang sepenuhnya disesuaikan yang dirancang untuk memenuhi kebutuhan proses spesifik Anda, keterbatasan ruang, dan standar regional. - Garansi 18 Bulan & Dukungan Teknis Seumur Hidup

Setiap pembelian sudah termasuk garansi kualitas selama 18 bulan dan dukungan seumur hidup. - Pelatihan Instalasi Gratis di Lokasi

Panduan instalasi dan commissioning ditawarkan secara gratis. - Kemasan kelas ekspor adalah standar

Semua peralatan dikemas dengan bingkai kayu sesuai dengan standar ekspor secara gratis. - Layanan Ekspor & Pengiriman yang Komprehensif

Kami menawarkan dukungan penuh untuk pengiriman LCL dan FCL, termasuk layanan pemuatan kontainer gratis di fasilitas kami. Untuk pesanan domestik di dalam provinsi, tersedia pengiriman gratis. Semua logistik didukung dengan dokumentasi yang tepat dan koordinasi yang tepat waktu. - Janji Kami: Kemitraan Jangka Panjang

Pesanan Anda menandai awal-bukan akhir-dari komitmen kami. Kami tumbuh bersama klien kami, di setiap langkahnya.

Mengapa Memilih Covna Stark

Bagian Pengolahan Air

200+ Sertifikat Paten

Lihat Lebih Banyak Produk

Panduan Pengolahan Air Industri

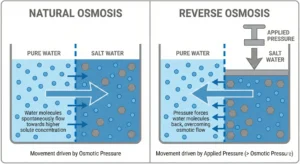

How to Improve Reverse Osmosis System Durability: Practical Methods and Best Practices

Baca Selengkapnya "

Januari 19, 2026

Panduan Pengolahan Air Industri

Beyond Filtration: The Engineering Logic and Working Principle of Industrial Reverse Osmosis Systems

Baca Selengkapnya "

Desember 23, 2025