Industrial & Commercial Water Treatment Systems Manufacturer | Stark Water

Water Treatment Equipment

- Tailored Engineering Solutions

We offer fully customized water treatment systems designed to meet your specific process requirements, space constraints, and regional standards. - 18-Month Warranty & Lifetime Technical Support

Every purchase includes an 18-month quality warranty and lifetime support. - Free On-Site Installation Training

Installation and commissioning guidance are offered free of charge. - Export-grade packaging is standard

All equipments are packed with wooden frame in accordance with export standard free of charge. - Comprehensive Export & Delivery Services

We offer full support for both LCL and FCL shipments, including free container loading services at our facility. For domestic orders within the province, free delivery is available. All logistics are supported with proper documentation and timely coordination. - Our Promise: Long-Term Partnership

Your order marks the beginning—not the end—of our commitment. We grow with our clients, every step of the way.

Why Chosse Covna Stark

Water Treatment Parts

200+ Patent Certificates

View More Product

Industrial Water Treatment Guides

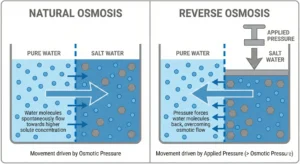

Beyond Filtration: The Engineering Logic and Working Principle of Industrial Reverse Osmosis Systems

Read More »

23 December, 2025