Industrial & Commercial Water Treatment Systems Manufacturer | Stark Water

Equipamento de tratamento de água

- Soluções de engenharia à medida

Oferecemos sistemas de tratamento de água totalmente personalizados, concebidos para satisfazer os requisitos específicos do seu processo, restrições de espaço e normas regionais. - Garantia de 18 meses e suporte técnico vitalício

Cada compra inclui uma garantia de qualidade de 18 meses e assistência vitalícia. - Formação gratuita sobre a instalação no local

As orientações de instalação e colocação em funcionamento são oferecidas gratuitamente. - A embalagem de exportação é padrão

Todos os equipamentos são embalados com estrutura de madeira de acordo com as normas de exportação, sem custos adicionais. - Serviços abrangentes de exportação e entrega

Oferecemos apoio total para envios LCL e FCL, incluindo serviços gratuitos de carregamento de contentores nas nossas instalações. Para encomendas domésticas dentro da província, está disponível a entrega gratuita. Toda a logística é apoiada por documentação adequada e coordenação atempada. - A nossa promessa: Parceria a longo prazo

A sua encomenda marca o início - não o fim - do nosso compromisso. Crescemos com os nossos clientes, a cada passo do caminho.

Porquê escolher a Covna Stark

Peças para tratamento de água

Mais de 200 certificados de patente

Ver mais produtos

Guias de tratamento de águas industriais

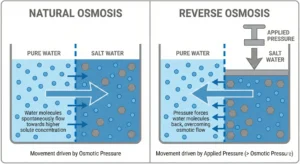

Beyond Filtration: The Engineering Logic and Working Principle of Industrial Reverse Osmosis Systems

Ler mais "

Dezembro 23, 2025